7 Steps to Safe Animal Transfers in Your Vivarium

Here are 7 key considerations before and during an animal transfer to provide you maximum protection and an ergonomic experience

13 Nov 2017

In a vivarium facility when transferring animals to a different cage or during basic housekeeping, it is important for the handling scientist to protect themselves from animal fur and dander, as well as contaminated bedding material. Biosafety cabinets are designed to safeguard scientists from such allergens and also to minimize cross-contamination between animals. Listed below are 7 things to consider before and during an animal transfer to provide you with maximum protection and an ergonomic experience during long vivarium procedures:

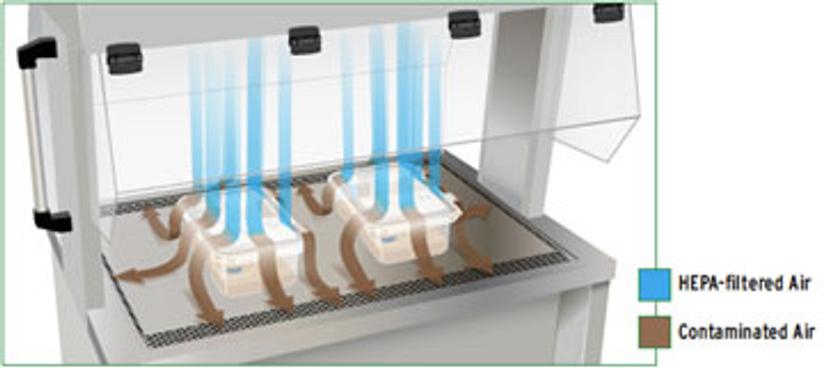

1. The flow of air in your biosafety cabinet

The airflow pattern — starting from the ambient room air to the HEPA-filtered air blowing into the cages, to the disposal of contaminated air from the cages — is an important consideration to protect both the scientist and the animals.

In the NuAire AllerGard biosafety cabinet, the airflow pattern moves in a uniform vertical pattern providing particulate-free air in the working zone. The air from the cages is then pulled into the vacuum slots around the work surface through the exhaust pre-filters and the exhaust HEPA filter.

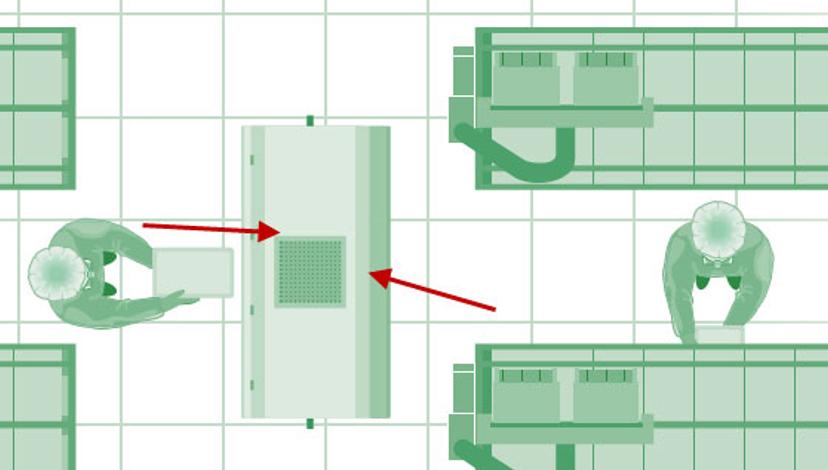

2. Dual access for easy aisle navigation

When multiple team members need to work in the same vivarium space, it helps to have a biosafety cabinet that provides dual access. This becomes particularly important when handling cages across narrow aisle spaces or for a workflow that requires walking back and forth between the cabinet and the cage space.

As a dual sided cabinet, multiple researchers can use the AllerGard NU-620 at the same time. An optional polycarbonate shield can be quickly installed in one side to modify the cabinet into a single-access unit, if required.

3. Expanded visibility through the front window

The front window, if designed poorly, can block one’s view across the cabinet. When handling pups or performing genotype tagging, a clear, expanded vision becomes critical. Poorly designed front windows that don’t offer a sufficient access opening can tempt users into risking several violations in safety protocols.

The front of the cabinet in the AllerGard NU-620 is designed to offer a clear, broad view of the workspace, ensuring nothing escapes your vision when in the vivarium cabinet.

4. An ergonomic setup for sitting or standing at the cabinet

Genotype tagging or experimental procedures that involve time-lapse intraperitoneal injection require extended periods of time at the cabinet. It helps to ensure that your cabinet is compatible for sitting and offers an ergonomic design for error-free workflows.

Proper ergonomics is a key feature of the AllerGard NU-620, where a ‘user knee space’ in the bottom half of the cabinet offers space to tuck in when seated.

5. A large work area

To avoid unsafe practices such as cage stacking while maintaining the need to deal with multiple cages at a time, it is always better to choose a cabinet that offers a large work surface. With an access opening of 14 inches, and a working surface area of 36 to 42 inches, the AllerGard NU-620 maximizes usability.

6. An in-built hand sanitizer

Hand sanitizers are no longer limited to the entrance/exit of a vivarium facility. The AllerGard NU-620 offers an in-built hand sanitizer as an add-on option to the biosafety cabinet to encourage hygienic practices immediately after your gloves come off.

7. An embedded shelf for storing cleaning sprays

Between different cohorts or in a facility shared by different labs, cleaning the cabinet is of prime importance to avoid cross-contamination. An embedded storage shelf, offered by NuAire as an add-on, that stores sprays, alcohol, bleach and all the necessary cleaning supplies makes it convenient. Plus, when in plain sight, you’ll never forget to clean your surface area after use.