A starting guide to customization for laboratory processes

An unbiased buyer's guide to automating your laboratory written by John Woodford, Kbiosystems

16 Oct 2023

In these changing and challenging times, the need to understand where and why to automate research and laboratory processes is becoming more critical than ever. Finances are stretched and the cost of just about everything is higher than ever before and spending valuable capex funding has to be considered at the highest level of benefit.

Kbiosystems and its UK based facility offer the highest level of expertise in concept, design and technology packages. It offers an open discussion process to design method and always involves the client throughout the process. Here, Kbiosystems provides an unbiased buyer's guide to automating your laboratory that will help with the solution finding process, whoever your end vendor is.

STEP 1: Do I really need automation?

This is the most critical and biggest question you should ask, before you start any conversation with a salesperson.

The need for automation and the processes that are and are not automation ready are two very different things. Firstly, assess the time it takes to manually run the process, how often do you carry out this process, and is it possible to maintain this manual step with other more critical automation for the surrounding processes.

This can often be simple tasks like moving plates racks or solutions from A to B one or twice a day – does this justify the expenditure to automate?

Maybe the overall process is environmentally critical, then a controlled process may mean this answer is yes, this must be automated. If no, then does the expenditure give the value added or would the funding be better spent elsewhere? There is no point in poorly placed automation.

Always enter the conversation with the mindset that you are the scientific lead and they are the automation lead, together you should be able to reach a solution.

STEP 2: Choose your expert

Automation companies globally all have their own levels of expertise and solutions that will be vying for the opportunity to supply you with their equipment. Consider the equipment carefully and listen to the vendors’ experts on what they can offer.

Take time to engage with several vendors offering the same solution. In reality they rarely are the same, that is of course unless you find resellers of OEM equipment, then you could be listening to the same thing over again. Due diligence in this area will help you avoid repetitive conversations.

You should be able to tell quite quickly into the conversations if they know what you need or not. If not, move on.

STEP 3: Understanding your user requirements specification (URS)

This term will often be used to list a formal process requirement. This essentially is your shopping list, you should detail every little fact no matter how small, even the simplest of process steps can be the difference between a successful automation project and failure at the acceptance stage.

The URS process at Kbiosystems usually starts with the overview, this details what you want to achieve from the automation and should cover hardware, process, and software requirements. Ensure that any operational validation or process compliance is clearly stated, for example, UL, IVD, FDA, etc.

The URS is a document that both you, the client, and Kbiosystems, the vendors, heavily rely on as the key to project success and delivery of the correct equipment you are expecting.

The final stage of any URS is the completion of project in a large-scale automation system. This should follow two significant steps to sign off against:

Factory Acceptance Test (FAT): this where the vendor will demonstrate the operational aspect of the system in guidance with the URS. Mechanical, operation and sometimes scientific process can form this process test. Once signed off the automation is ready for shipment and installation on customer site.

Site Acceptance Test (SAT): This is basically a repeat of the FAT in a live situation. This is where any transit or installation errors become very apparent. Always try to have the same people attend the FAT and SAT, as they know what to expect.

A URS is not required for every automation acquisition, but the principle of this document remains the same for your thought process before purchasing any equipment:

- What do I want it to do?

- Does it fulfil the requirement?

- Is it fit for purpose?

STEP 4: The build

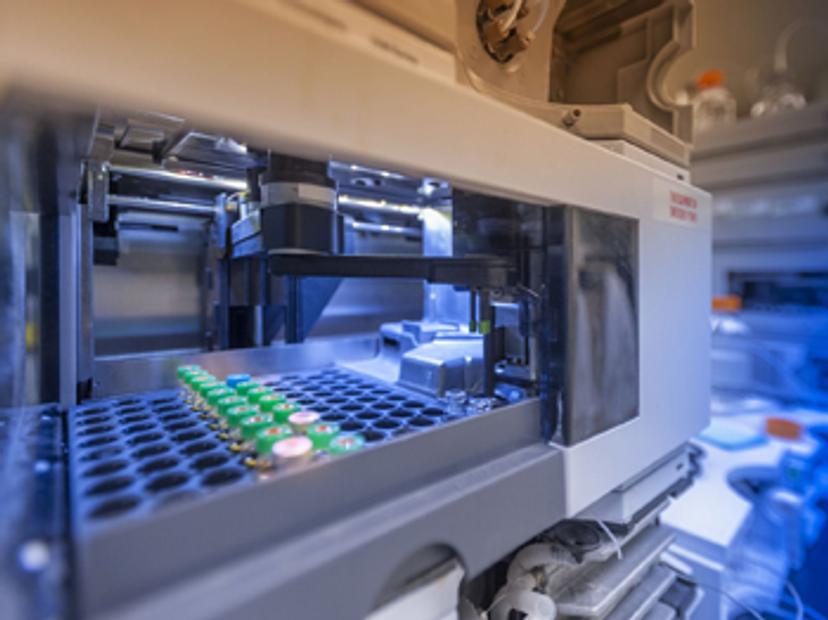

All vendors should embrace your input and interest in the build process. Make sure you have regular meetings and conversations regarding the process and working methods being used, especially if the project is 100% customized for your needs and applications. The automation is an engineering event and must adapt and work with your scientific applications – make sure you educate your vendor with the scientific reasons and requirements. It is the vendor’s role to make sure you understand the engineering capabilities and limitations.

Remember automation loves consistency and repeatability – that is its key benefit to the science research process.

Once the build is over, if an FAT is offered, make sure you have, supply, or take all the relevant items to be processed. Sometimes chemical or biological elements cannot be simply sent or even used, so make sure that the test protocols to sign off with are robust and close enough to your operational process. These will be what you are accepting the equipment on, unless there are more specific tests to help during SAT.

FAT and SAT are like mini insurance policies for both parties. Never deviate from the URS at this stage as this will only cause problems later, make sure nothing is misinterpreted and the FAT and SAT match your process as a minimum.

Solutions from Kbiosystems

This guide is only an overview into the world of purchasing automation solutions and is by no means exhaustive in the overall process, this largely depends on the size of project – the bigger the project the bigger the documentation.

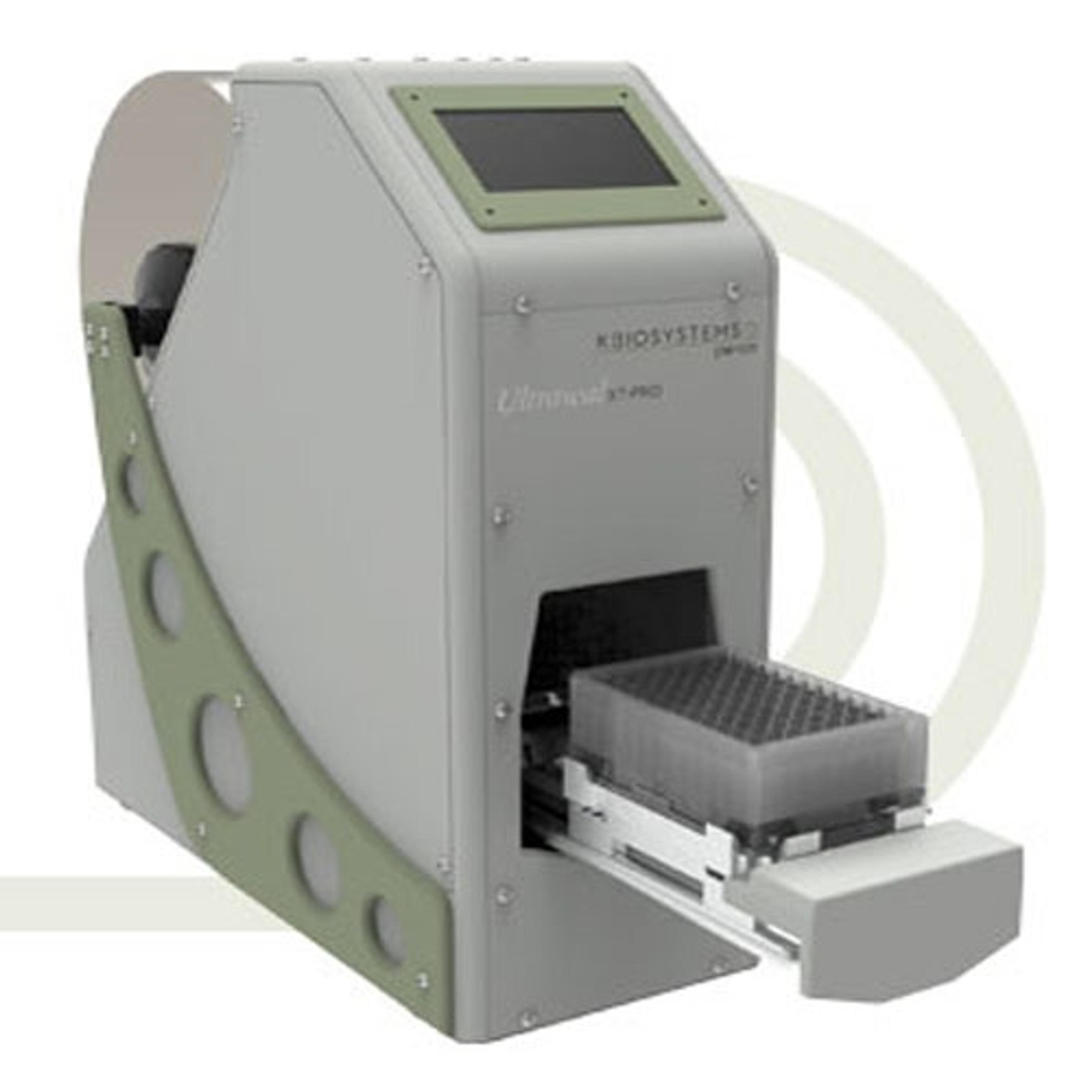

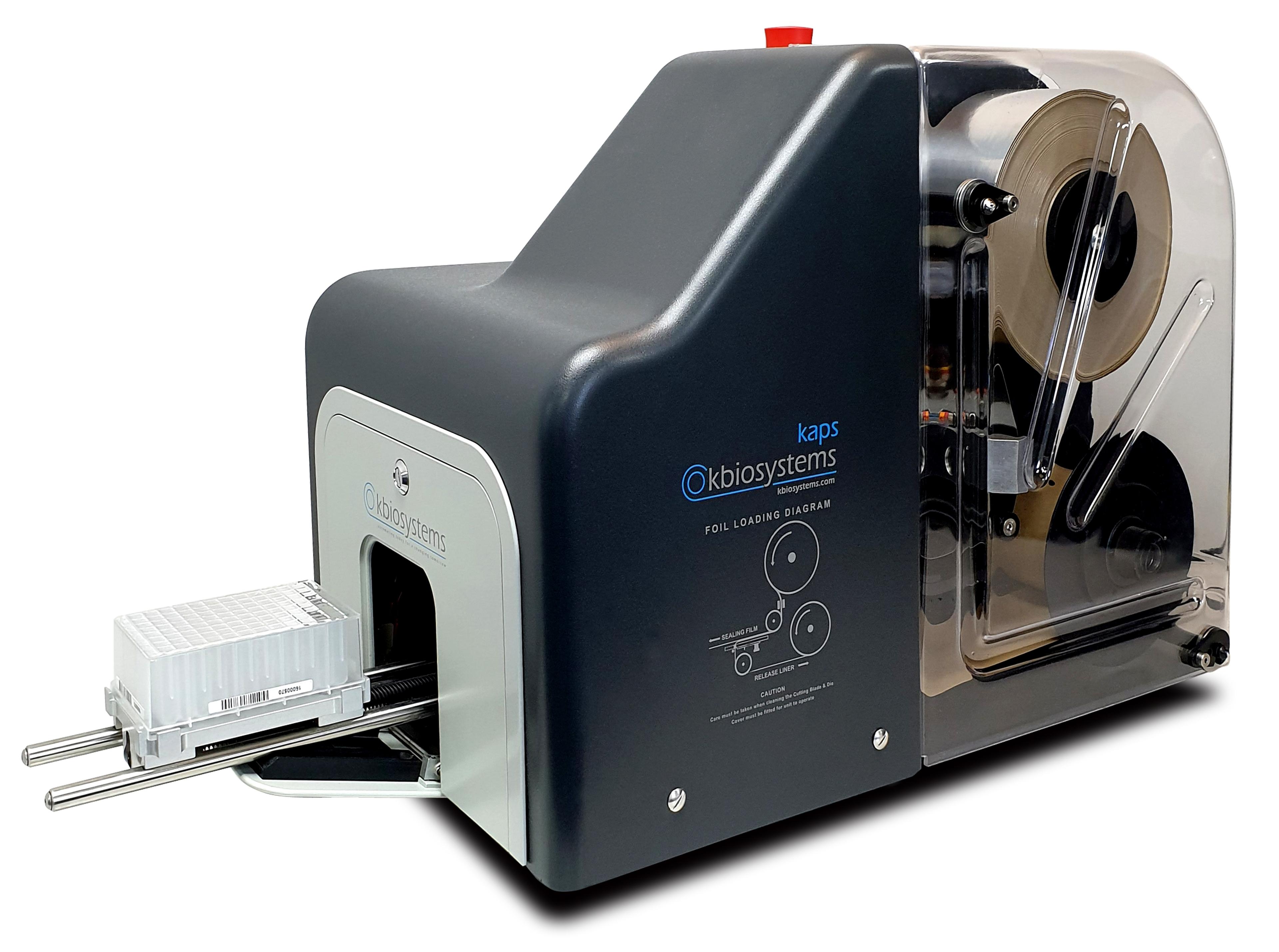

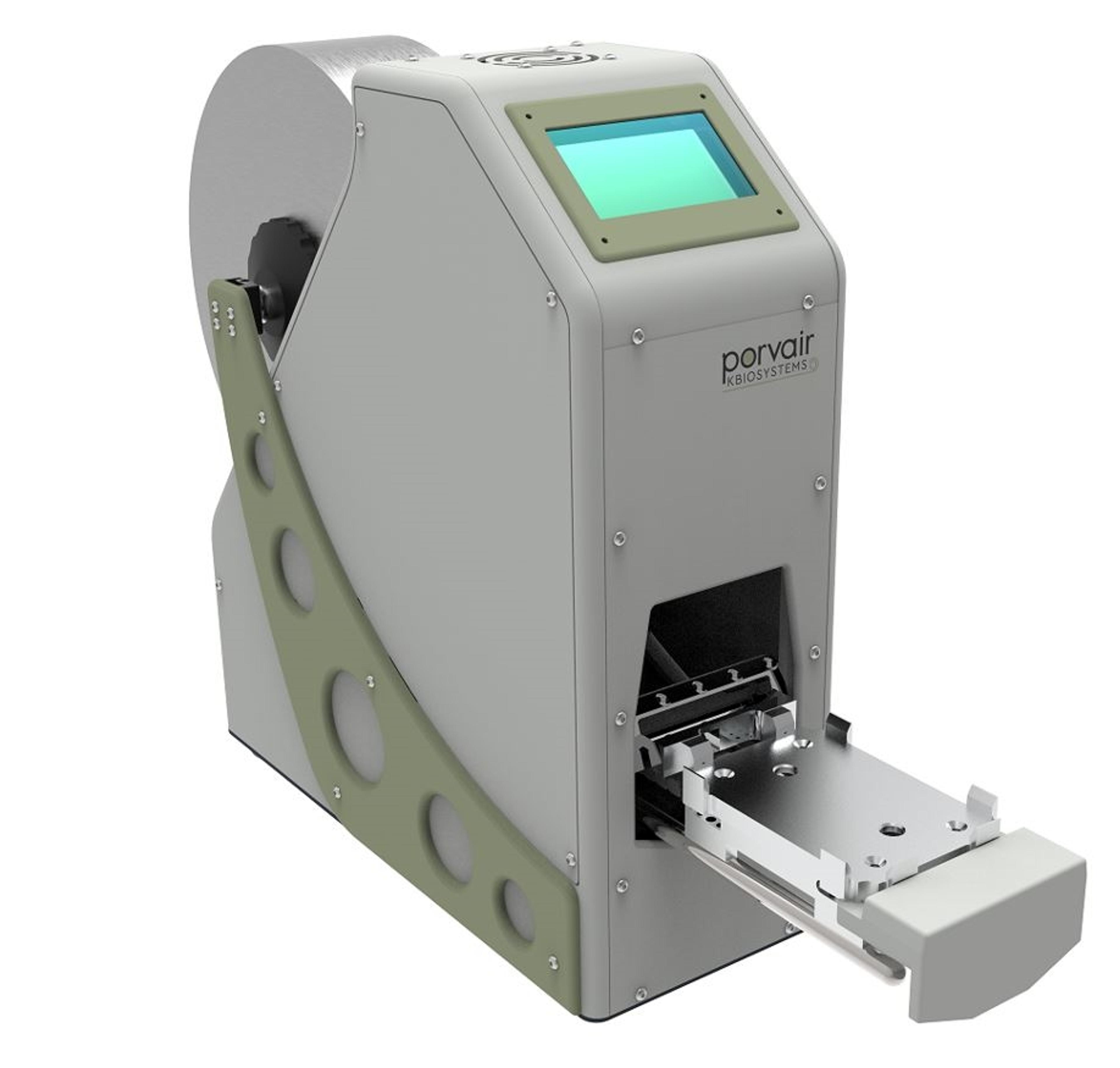

Kbiosystems offers an extensive range of services, conceptual discussion, pre-design 3D modelling, formal electromechanical design, manufacture and assembly and to complete the loop, post-sales service and support.

As part of a large UK PLC, (Porvair PLC), Kbiosystems forms part of a group of companies that service the scientific marketplace. Alongside automation, Kbiosystems supplies and manufactures plastic and glassware consumables, custom design consumables, and environmental test equipment.

Kbiosystems and its sister companies (Porvair Sciences, J.G. Finneran, Ratiolab and SEAL Analytical) work closely together and can offer a wide range portfolio of products.