Achieving end-to-end digital transformation: How a prolific diagnostics laboratory improved its overall efficiency by embracing automation

Get a closer look at how automation and digital solutions can transform clinical operations – from task-specific activities to operation-level workflows

16 Jun 2022

In a high-throughput, busy clinical testing laboratory, every minute matters.

Unexpected delays caused due to re-runs or tedious sample loading steps can have a direct impact on the time required to produce test results, in turn influencing the patient’s health outcome. As such, incorporating relevant automation platforms in clinical laboratories not only accelerates turnaround times but significantly improves the overall quality of testing.

In this SelectScience® article, we take you inside one of India’s most prolific diagnostic laboratories, Dr Lal PathLabs, offering over 5000 different diagnostic tests to patients spread across multiple metropolitan cities. Having experienced high sample volumes during the COVID-19 pandemic and gradual organic growth in recent years, the team has leveraged several automation systems to scale up its operations while keeping its high standards of accuracy.

Identifying opportunities for automation with a thorough review

To operate on a larger scale, the teams at Dr Lal PathLabs narrowed down the key challenges they were facing. First, the turnaround times needed to be more consistent, especially when samples were shared between instruments for different tests or were received during peak service hours. Reducing variance in turnaround times both in the company’s main reference lab as well as in its many satellite labs would make the overall operations more consistent and predictable, making it easier to scale things up if necessary.

Next, the analytical instruments on-site needed to be robust enough to handle the high sample load coming in daily. Equally, the technical staff processing samples and performing the tests also needed to have the capacity to handle higher throughputs during busy periods. “We wanted to increase our capacity to regularly manage high sample volumes,” says Dr. Reena Nakra, the Principal Director of Lab Management and Technical Excellence at Dr Lal PathLabs. “While we already had task-specific automation in place, we realized that as we continued adding more instruments to increase the throughput, we would also need to keep increasing manpower to handle these instruments. That is when we started thinking about bringing in integrated, multidisciplinary Total Lab Automation (TLA) configured to our workflow that can free up the hands – and minds – of our technicians so they can focus on higher-value tasks.”

Dr. Reena Nakra, Dr Lal PathLabs

Valuable time at Dr Lal PathLabs was lost on activities associated with sample-based checks, such as handling sample rejects, or workflow-based checks to examine the health of the instruments. Using advanced software to automate these time-consuming steps would result in improved operational efficiency throughout the company.

Working in collaboration with Siemens Healthineers, the core team at Dr Lal PathLabs zeroed in on the key issues they wanted to improve:

- Increase the volume of testing

- Eliminate time-wasting activities (no more “running around” to locate shared samples, reducing aliquoting steps, and minimizing sample touchpoints)

- Enable real-time status updates so that the location of each sample can be traced with accuracy

Leveraging automation at different levels: Task-based and operations-based

“We contracted Siemens Healthineers to design, implement, install, and support the Aptio® Automation on the ground floor of our national reference lab located in New Delhi,” shares Dr. Nimmi Kansal, Technical Director of Clinical Chemistry and Biochemical Genetics. “This automation solution connects four Atellica® Solution system lines to a single track that includes 15 analytical components – nine for immunoassay and six for chemistry – in addition to two non-Siemens Healthineers systems for specialized tests. This custom configuration supports the lab’s 1600 tubes/hour workflow.” Combining this multidisciplinary testing is part of the team’s total laboratory process automation (TLA) strategy where repetitive, routine tasks that had been performed manually by staff are also automated with pre- and post-analytical processing robots and coupled with digital intelligence.

While the Atellica Solution analyzers automate specific testing for immunoassay and clinical chemistry analyses, the Aptio Automation system provides operational automation to the workflows, connecting several individual instruments and accelerating sample handling. Additionally, to better manage the data generated by these instruments, the team also implemented a data management software, namely, the Atellica® Data Manager.

“The Atellica Data Manager helps us automate advanced sample processing and repeat testing workflows using data-driven rules and built-in functionality,” notes Dr. Saloni Khera, Principal Director at a satellite lab. “It provides a centralized management across multidisciplinary instruments and labs. Based on predetermined quality criteria, we’re able to evaluate and verify patient results automatically, and review flagged results that require further action. This adds objectivity and consistency to our review process and ensures that we bring added focus to abnormal results.”

Automating data management, at first, didn’t seem like a necessity. However, as the number of tests running on different instruments increased, the need for managing data became more apparent. “When we got our first Atellica immunoassay system, we didn’t use the Atellica Data Manager as we thought we would be able to manage without it,” says Khera. “But when we took on a second Atellica system, having the data manager enabled us to dynamically balance the testing loads as if the two systems were “talking” to each other. Without the Data Manager, we would have seen a lot of inventory wastage.”

Achieving faster sample turnarounds and higher revenue potential

Since automating specific tests and workflow operations, the overall efficiency, test quality, and business potential at Dr Lal PathLabs have seen significant improvement.

“By using in-built aliquoting algorithms, we immediately went from 4000 aliquots a day to only 1500 a day, and with Atellica Data Manger’s advanced sorting logic, we have now further reduced it to less than 250 a day,” says Kansal. “Consolidating the test menu has helped us to reduce aliquots as the maximum possible testing can be completed from a single tube. Moreover, automating the necessary aliquoting has eliminated the risk of manual errors and spillage. In being able to make the most of each sample with fewer aliquots, our sample rejection due to insufficient quantity has reduced. In turn, this has had a positive impact on reducing turnaround times - reducing cost and manhours spent in identification and probable sample recollections. We’re now able to provide better patient care while maximizing our revenue potential.”

Contributing to the new and improved patient experience offered by Dr Lal PathLabs, the facility has also enhanced the quality of its testing reports in addition to faster turnaround times. Reporting accuracy is now duly controlled using auto-verification settings. In addition, the lab monitors patient moving averages to proactively monitor instrument performance trends without the added costs of quality controls.

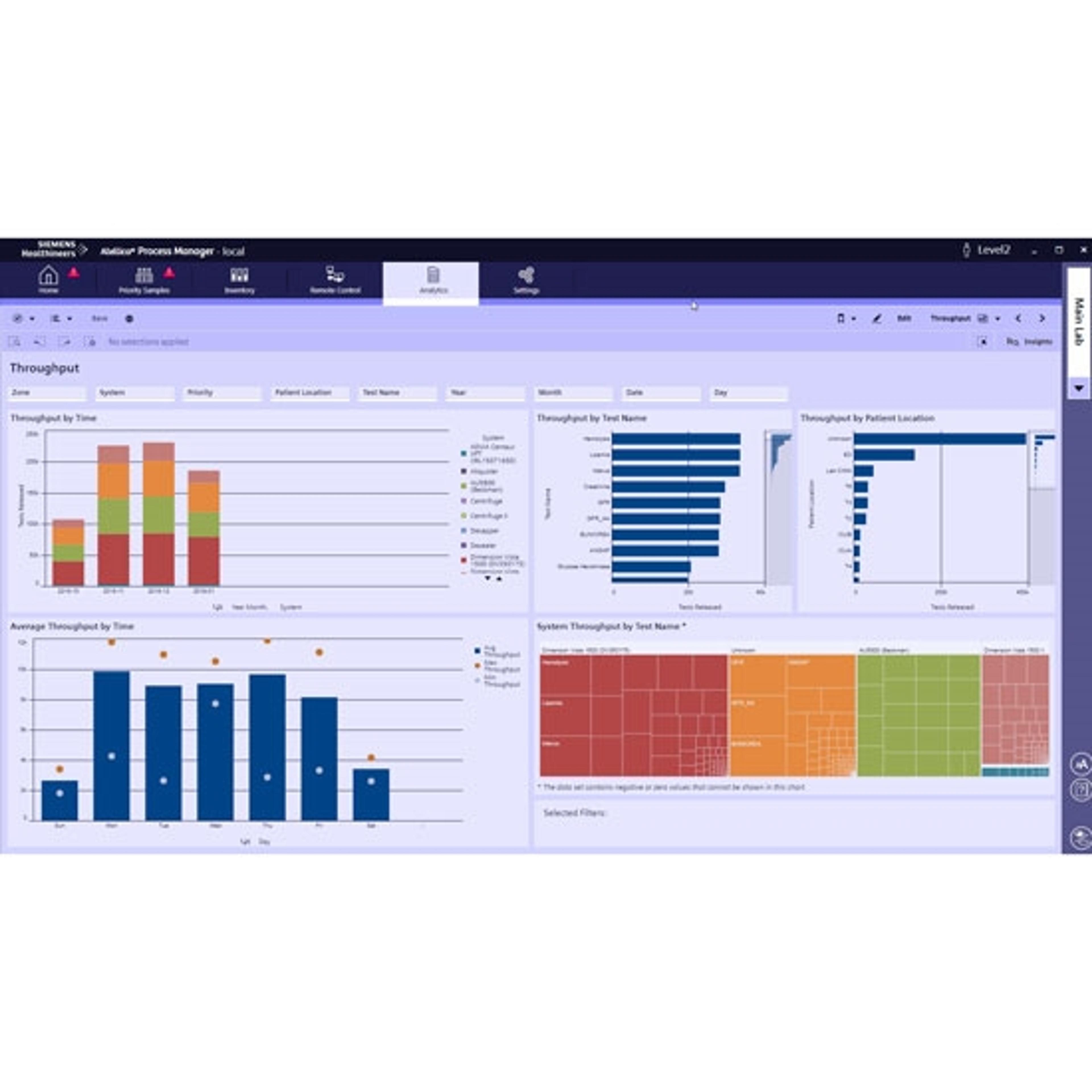

Many of these workflows have been optimized and standardized with the Atellica® Process Manager, a software used to control workflows in a centralized manner. By implementing “rules” and customizing alerts, the entire operation, including instrument status and inventory lists, can be monitored remotely. Having these real-time updates came in handy during the pandemic. “At the peak of COVID-19, there was a sudden surge in sample volume and testing. We had a huge number of tests of the same kind – requiring only a few test parameters,” recalls Nakra. “The Atellica Process Manager improved the visibility of the test requests arriving at the lab and helped us prioritize and plan our day better. By monitoring reagent availability remotely, we were able to handle high workloads without significant disruption in services. At one point, we pulled off four times the usual sample volume with only half the staff on site. This was only possible because we had process automation and data management systems in place.”

Learn more about automation based on the experience of different labs:

- Read how a hospital capitalized on the same instruments, automation, and IT as this reference lab. Download free case study >>

- Learn about the design and project implementation processes surrounding total lab automation. Watch video >>

“Going completely hands-free is the dream.”

“To help us scale even further and maintain high quality at every step, automation should ideally require minimal dependency on people and expertise. We often ask ourselves: Is there a way to completely fool-proof the system?” says Nakra who is currently responsible for driving automation and digitalization at Dr Lal PathLabs. “Atellica Solution is definitely a step in the right direction as it is an intuitive machine. Moreover, Siemens Healthineers provides education modules that make it easy to train users.”

“Our wish list for advanced automation would be to standardize the many consumables that a clinical lab encounters,” Nakra continues. “Tubes, barcodes, and other consumables will need to be standardized so they can seamlessly enter into the workflow track. Our company uses its own vacutainers to circumvent this variability. In any case, the Siemens Healthineers team was very flexible and agile in validating different tubes for the track.”

In being able to keep up with increased testing demands and stay at the top of its industry, Dr Lal PathLabs will continue to invest in modern automation. “Automation in clinical applications is not yet fully seamless. Going completely hands-free is the dream,” says Nakra. “In the future, it would be good to have an automated clinical decision system that can support fast, comprehensive, and smart testing with minimal human intervention.”

Aptio, Atellica, and all associated marks are trademarks of Siemens Healthcare Diagnostics Inc., or its affiliates. Aptio Automation is manufactured by Inpeco and is exclusively distributed by Siemens Healthcare Diagnostics Inc.