Compliant solutions: How to choose the right balance for your laboratory

Discover the latest analytical weighing solutions helping users remain compliant for the development and testing of cosmetics and personal care products

25 Apr 2022

In an ever-changing world of cosmetic and personal care innovation, formulators are facing huge pressures to remain compliant and meet increasing consumer expectations. Innovation in the cosmetics, personal care, and drug industry is dominated by the advancement of research and development in formulation chemistry. Formulating cosmetic and chemical products can present a range of challenges, including retailer and consumer demands, product safety and performance, media scrutiny, ingredient quality, technological and time limitations, and the need to comply with strict regulations.

In the case of cosmetics, every ingredient contained within the product must be scientifically assessed and approved, whether that be preservatives, emulsifiers, thickeners, and coloring agents, to name but a few. In the pharmaceutical industry, formulators must repeatably perform accurate weighing to prevent devastating consequences, such as patient overdose.

In this article, we provide a collection of essential resources to help users improve their weighing processes, and present key information on data storage, compliance, and the latest weighing technologies. We also explore checkweighing and outline how this method is essential for any manufacturing business wanting to optimize their workflows and protect consumers. Plus, meet the laboratory balance must-have, delivering precision, repeatability, and reliability.

Principles of checkweighing: Meet the perfect weighing solution

To protect consumers and patients, the filling weight of finished goods and drugs must be checked gravimetrically. Checkweighing is an important method used for safeguarding food, pharmaceuticals, and packaged goods. A checkweigher can either be an automatic or manual machine designed to check the weight of a given product, which will reject any product weighing over or under a specified limit via removal from the production line.

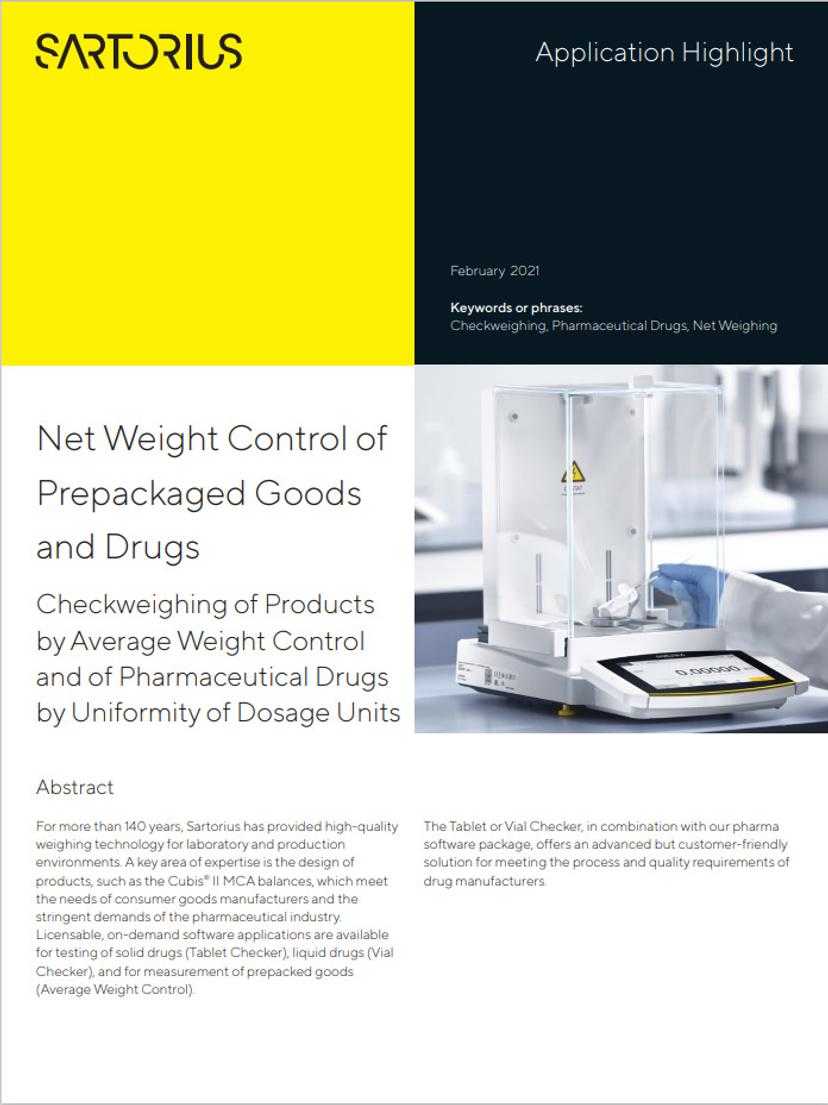

Sartorius have provided high-quality weighing technologies for over 140 years, supporting users working within both laboratory and production environments. This application note explores the Cubis® II MCA balances, a range of balances designed to meet the needs of manufacturers producing consumer goods and pharmaceutical drugs. This resource outlines the important guidelines set in place by the European Union to protect consumers, and highlights two key checkweighing applications, termed average weight control and uniformity of dosage units. While both approaches check if a sample weight is within allowed tolerances, they have a different scope. For average weight control, the lower tolerances are mandatory, while for pharmaceutical drugs, the lower and upper tolerances are mandatory. The software applications offer process specific controls for compliance to the specific guidelines or monographs. The results are calculated directly on the balance and displayed well arranged on the large touch screen interface. The aim of uniformity of dosage units testing is to prevent under- or overdosing of drugs.

This application note also explains the importance of data integrity, and how to effectively ensure users remain compliant. We also highlight how the Cubis® II MCA combined with the Pharma software package from Sartorius enables users to easily meet strict regulations by ensuring tests are carried out in a timesaving, precise, and regulation-compliant manner.

Data storage in the digital era

Technological advancements have enabled us to transition from traditional paper-based data storage to digital storage systems. Data is a valuable asset to many businesses, and the safe and effective storage of data is vital, particularly as security and regulatory compliance becomes more complex and changeable overtime. It is essential that companies have access to a robust data storage system for storing information, such as client data, analytical data, and financial data. Databases also provide a central storage place for data, and help deliver easy integration into different software systems, such as enterprise resource planning (ERP) and laboratory information management system (LIMS).

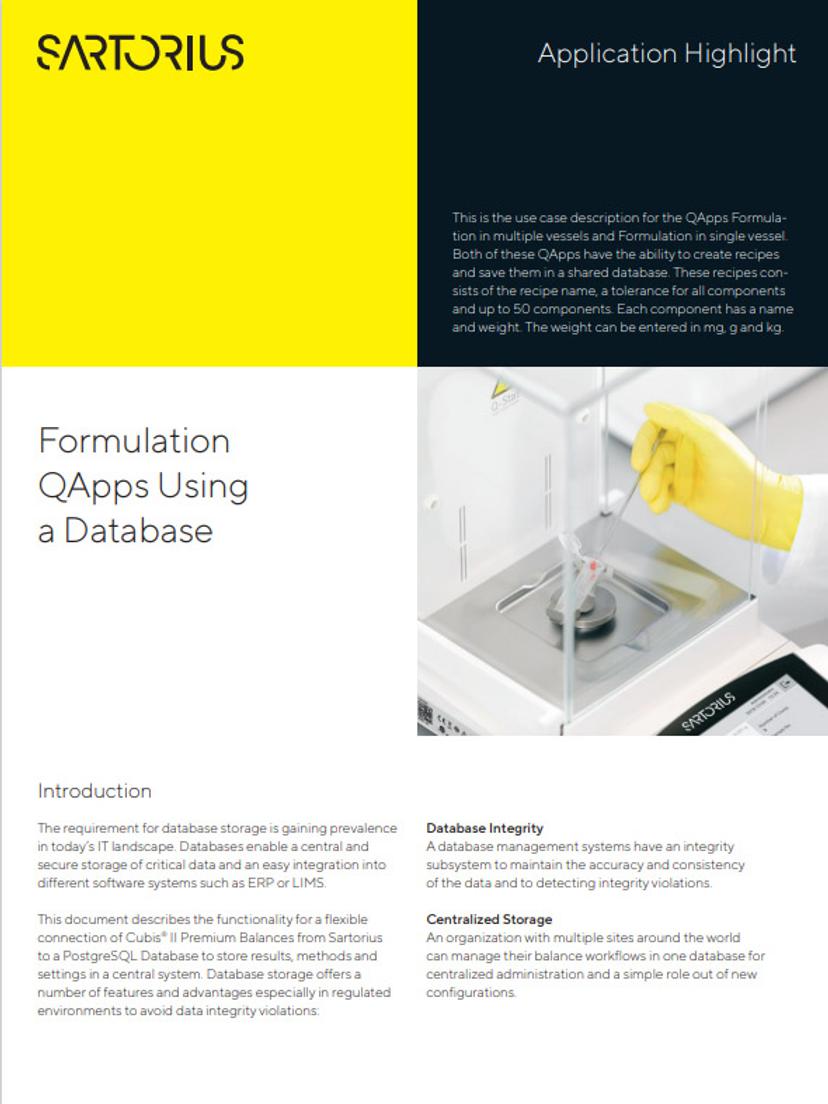

This application note explores the functionality for a flexible connection of the Cubis® II Premium Balance to a PostgreSQL database, to effectively store results, methods, and settings in one central and secure system. This system also includes integrity violation detection, unauthorized access restriction, backup and recovery facilities, and also enables organizations with multiple sites around the world to manage their balance workflows in one single database. This resource also discusses the importance of formulation in the product development and production process, and explains why global companies must have a specific formulation produced identically at all sites, so changes to a recipe can be effectively rolled out. Moreover, you’ll find out how to manage recipes in a local or central database located on the Cubis® II balance to ensure a specific recipe is produced correctly on all balances within a company.

Learn how to increase safety and efficiency with the latest software solutions for the Cubis® II balance, including QApps and Fireware. This software has been specifically designed to automate weighing workflows for maximum performance and compliance. This free download explores the latest software updates for QApp and Fireware, including task creation, role management extensions, optimized memory usage, timer-controlled actions, and average weight control, which allows users to select between single tare, tare mean, tare mean (individual measurements) and enter tare, facilitating reliable, safe, and stable product quality to build consumer trust.