Correlating Structural and Mechanical Properties Over Time: The Fourth Dimension of Materials Science

Find out how X-ray and focused ion beam microscopy are helping researchers to characterize the structure of materials

2 Jan 2018

Nikhilesh Chawla is Fulton Professor of Materials Science and Engineering (MSE) at Arizona State University, Tempe, USA, where he studies the mechanical behavior and modeling of advanced materials. In this exclusive interview, SelectScience® speaks to Prof. Chawla to find out more about his work.

SS: Please describe your work and the need for your current projects in 4D materials science

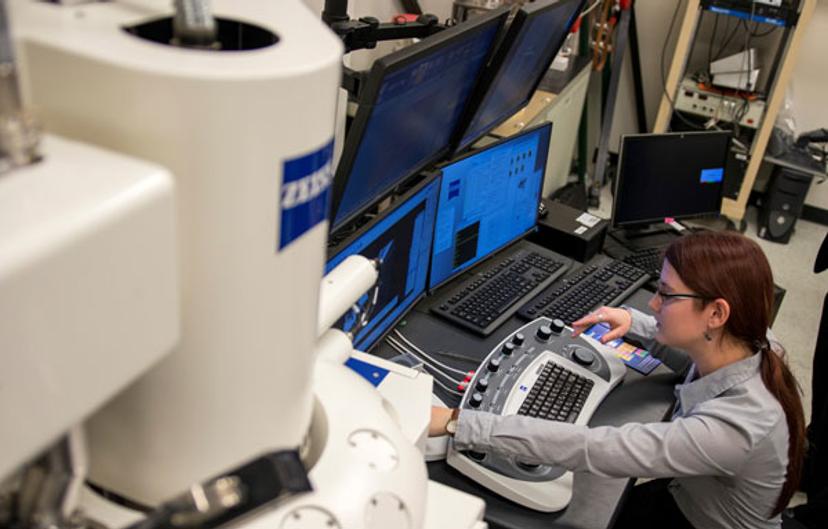

NC: My work focuses on correlating the structure of materials to their mechanical properties. This involves studying how materials behave under different loading conditions, whether it be cyclic loading, corrosion, mechanical loads or even electro-migration – things you’d see in interconnects in computers, laptops, phones and those kinds of devices. With our ZEISS instruments, and the community in general, we have a variety of different instruments that we can use to characterize the structures of materials in 3D, whether with X-rays or focused ion beam (FIB) techniques. With the technology available to us, we can now correlate those structural features with mechanical properties, which is really a game changer.

SS: Which ZEISS microscopes do you use and why?

NC: We use ZEISS Xradia 520 Versa for X-ray microtomography. We can use this system for imaging at fairly high resolution. The nice thing about this particular instrument is that we also have a diffraction contrast tomography system, LabDCT, so for metallic materials we can obtain information about the crystal orientations and the crystallography of the material. If we couple that with the imaging, this combination of technology is very powerful for correlating datasets.

We also use a ZEISS Auriga FIB-SEM to get down to the nanoscale, from there we can do cross-sections and compositional analysis, or even carry out destructive serial sectioning at the nanoscale. We use this instrument so that we can take a correlative approach, linking datasets from the X-ray realm, which is more on the micrometer scale, to the FIB realm which could be close to 10s of nanometers. We’re also using software called ZEISS Atlas 5 that ZEISS has developed. You can actually go to the X-ray system, find a region of interest, and then go back to the FIB and mill a very small region that you’re interested in. It is almost like going out to a football (soccer) field and then zeroing down on the penalty spot, something like that.

SS: How do you work with ZEISS to achieve your research objectives?

NC: ZEISS is a very forward-looking company, I would say, in terms of their engagement in science: they’re very interested in the kinds of applications that we are looking at. We work with the scientists at ZEISS on troubleshooting issues that are relevant to our particular applications, or on solving particular problems we’ve encountered. Often times, between us, we come up with new ideas and new approaches to getting the answers that were looking for.

SS: What is the future of your research?

NC: I think the future really lies with something we’re just starting to look at now: time dependence. Time dependence, or the dynamic evolution of the structures of materials, is really pushing the state-of-the-art, in terms of how these structures are changing and over what timescales. One of the big challenges now is that when you start to incorporate the fourth dimension as we call it, which is time, datasets become very large, and handling those datasets becomes difficult. Being able to archive that data and find the little needles in the haystack that we’re looking for is going to become quite a challenge in the near future.