Efficiently manage your biorepository and maintain high-quality data

Watch this on-demand SelectScience webinar to learn about STARLIMS and how it can be used to support the entire life cycle of your samples

6 May 2020

There are multiple software solutions in the market to help manage biorepository sample information. However, many solutions are geared towards merely managing the inventory of your samples. True biorepository solutions need to go beyond inventory control, particularly for laboratories where process compliance is key.

In this on-demand SelectScience® webinar, Karla Paulson, of Abbott Informatics Corporation, explores the features of the STARLIMS integrated solution for biobanks to support the entire sample life cycle, which follow industry best practices.

Read on for highlights from the live Q&A session or register to watch the webinar at any time that suits you.

Register NowQ: What interface does STARLIMS support for nucleic acid extractions and quantification?

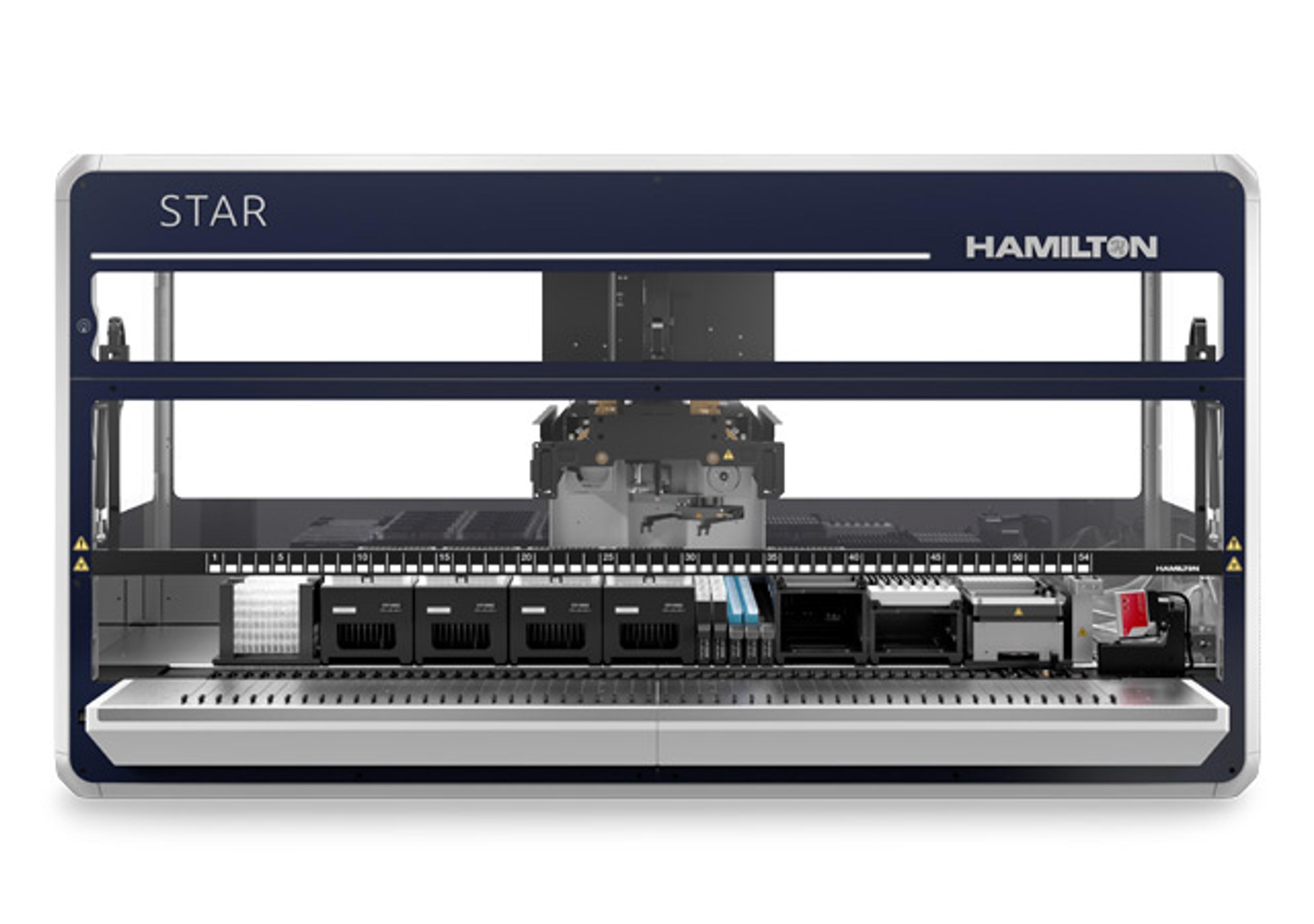

KP: For nucleic acid extractions, we've done interfaces with NanoDrop, Hamilton Liquid Handling STAR and just recently with BioTek Epoch. Since each customer uses different instruments for their nucleic acid extractions and quantifications, we aim to have different interfaces available. If a customer uses an instrument that we have done an integration on before, we don't want to start from scratch. We’ve already leveraged that integration. That’s another thing that we're building, an internal library for integrations with instruments in the STARLIMS.

Q: When using the mobile application at a collection site, is it possible to scan something associated with the patient information to that kit?

KP: Yes, we can scan patient information data associated with it. The example I had here in the content library for this sample kit collection shows that. If we know the subject ID or a patient ID, it can be scanned, and the information data will be loaded. If it doesn't recognize the ID, it gives the option to enter the information of the subject. When it comes to patient data and customer implementation, we need to check the customer needs because not all the customers have the same patient data collection requirements. It will vary. If it’s for research, it’s usually just an ID.

Q: On average, how long does it take to implement an external interface with STARLIMS?

KP: I can tell you that it varies, but it can be as fast as one week. I would say that 2-3 weeks would be the average, but it depends on the external system. For instance, when we had to implement an external interface with Hamilton, it only took one week. This is because the external system had a very good documented API which makes a big difference. If we have access to the vendor or the documentation of that external system, then implementation will not be complicated.

Q: Does the mobile application support all functionalities of the web version?

KP: We are currently in the process of adding more features in the mobile app and trying to prioritize certain transactions to be implemented. For instance, anything that helps the user to do real-time tracking of samples is a good candidate for the app. In some situations, there are storage locations that are inside freezers. In those scenarios, it makes sense to have a mobile app. There will also be some transactions that won’t be applicable for the mobile app, so we must prioritize the functionalities that provide more value. Right now, we are in the process of implementing manual aliquoting processes which could be a solution for laboratories that do not have facilities or space to have automated liquid handling instruments. User experience is very important to us, so improving the UX is what we are also focusing on.

Q: So how does STARLIMS handle aliquoting when it's done by an automated system such as the Hamilton?

KP: When it comes to aliquoting, we provide two options: manual and automated. The manual option is similar to aliquoting for the Hamilton. This is because Hamilton allows you to send all of the information. The LIMS will calculate and check all the different parent samples that are going to be used for aliquoting. This information that will be provided to the Hamilton will include specific positions that they need to go in, the destination containers, the volumes of the aliquots, etc. The Hamilton system is expected to execute this according to that plan. The plan that we typically provide is manually fed into the Hamilton. When the Hamilton finishes, it will try to aliquot whatever the LIMS tells it to do. If the Hamilton couldn't aliquot certain samples, there needs to be an additional check such as a quality control check. Since the interface will be bidirectional, we must obtain these aliquots and log them into the system. We also need a user to be quality checking because we could have a situation where a tube is empty after being aliquoted by the Hamilton. Having a solution for addressing those exceptions is important when it comes to automated aliquoting.

Learn more about STARLIMS integrated solutions: Watch this webinar on demand >>