Experts discuss the importance of sample preparation in dissolution testing

SelectScience speaks with sample preparation, dissolution testing, and filtration experts on how to improve the robustness of your dissolution methods

14 Nov 2022

Filtration is one of the most critical parameters of the dissolution process, with the selection of the right filter central to avoiding retesting. There is a broad range of filter types available on the market with different membranes and chemical compatibilities, as a result choosing the optimal filtration for challenging samples can be difficult.

In this article, Bryan Crist, President of DissoAssist Consulting, Dan McElroy, Senior Global Product Manager, Syringe Filters, at Cytiva, and Jakub Koceba, Global Product Specialist – Lab Filtration at Cytiva, discuss how to evaluate and select the right filtration tools for even the most challenging samples to improve the long-term robustness of your dissolution methods.

How can I ensure I am using the optimal choice of filter for my dissolution testing?

JK: There are many factors to consider when choosing a filter for your application. When choosing a good membrane, the first thing to consider is its chemical compatibility with your sample type. Think about the hydrophobic or hydrophilic nature of the membrane and any potential solvent absorption. You want to choose a membrane that will have the lowest level of solvent absorption as this absorption makes the material swell, reducing pore size and affecting the performance of the filter. Some solvents might also chemically attack the material, releasing extractables into the filtrate which should be avoided. You also don't want to clog the filter, so consider a prefilter if you have messy samples.

What are the potential implications of choosing the wrong filter for dissolution testing?

DM: Dissolution is used to determine the amount of drug in solution at a certain time point. We need to remember that these drugs are going into living beings. The drug needs to work as it was designed and dissolution testing is part of the verification process before drug release. Getting that wrong could be detrimental from a human health perspective.

BC: The filter needs to ensure there is no undissolved material and clean up the sample for analytical measurement. Dissolution is one of the few tests where you have an elaborate preparation, which is why dissolution itself is often automated because it is a very technique-laden test. The filter must properly clean up the sample for measurement without jeopardizing the integrity of the filtrate.

What are the biggest misconceptions when it comes to dissolution testing sample preparation?

By optimizing your filtration you’re ensuring the quality of your analysis.

Dan McElroy

Cytiva

DM: The general view of the sample filtration step is that it's not an important part of the process and that the choice of the filter to be used will have little impact on the results. This isn't the case; filtration plays a crucial role in dissolution testing. With an improper filtration step, the quality of your samples that you’re then going to do analysis on will be greatly affected. By optimizing your filtration you’re ensuring the quality of your analysis.

BC: Another big misconception is that filters can be reused. I want to reinforce that these are disposable filters. You can have carry-over and binding issues so it's not good laboratory practice to be reusing filters. Some people have looked at centrifugation as a method for cleaning up a dissolution sample. What you're doing through a centrifuge is putting the product into a solution, you're not separating it. You've just moved the analyte of interest to another place with a lot of vibration and some extra heat. In no way is the integrity of the filtrate preserved through this process.

Are there different filters available depending on whether you carry out manual or automated dissolution testing?

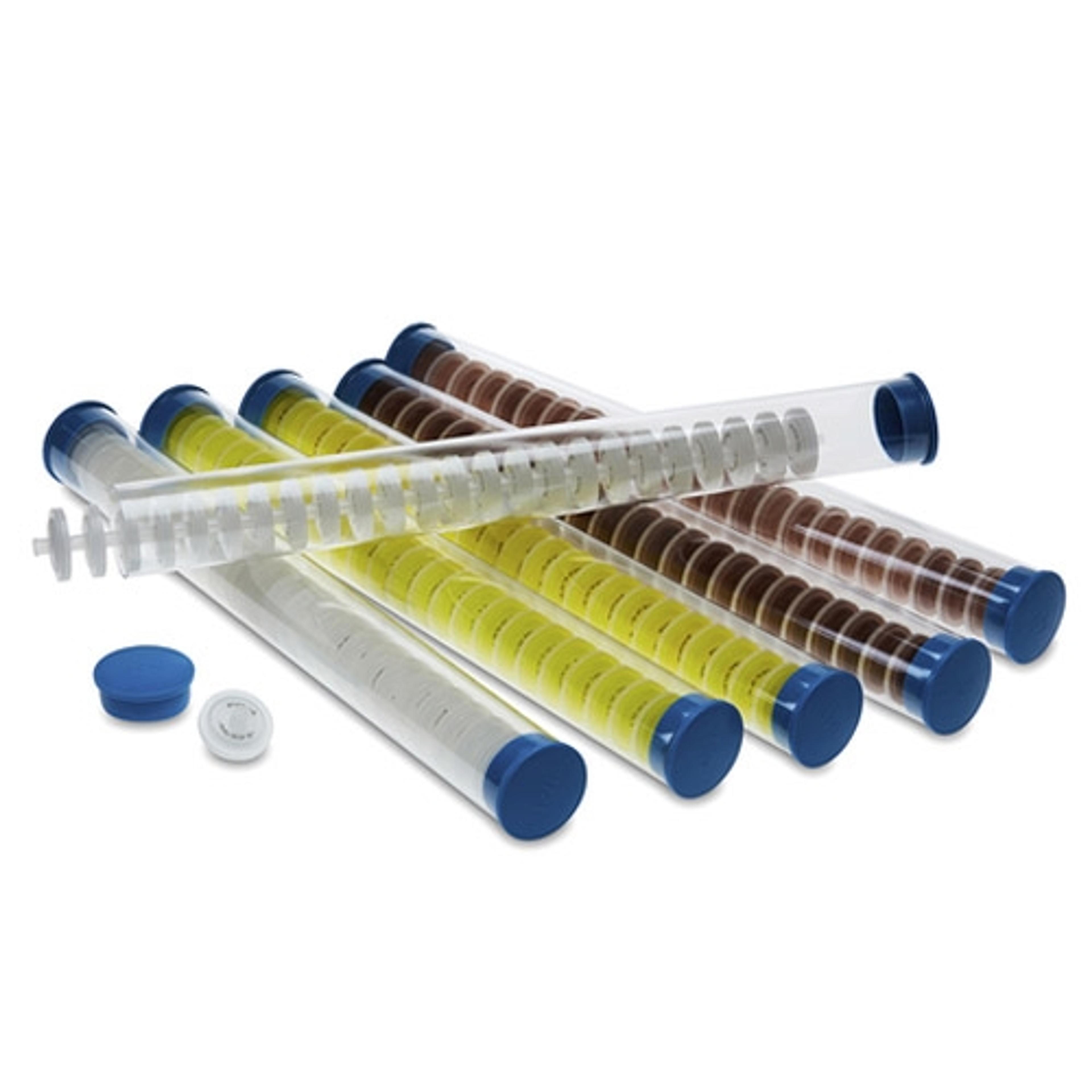

DM: There are filters specific for manual and automated dissolution testing. In manual testing, you have different diameter sizes of filter, and there's not much emphasis put on the shape of the filter. It's all about what happens at the membrane level. With automation, you have significant features that are built into the filters. We have several filters and filter kits such as the Whatman™ Roby Filter Validation Kit which have domed housings. The domed housing, as well as the inlet and the outlet, are designed to stack together. Whenever you're using an automated filter changer, you need to make sure that the filter can easily move through the changer. These domed housings and the ability to stack are just two of the main features that you would see in filters that are primarily used for automation.

Not only are Cytiva filters available in a traditional single syringe filter format, but we also have them in plate format. In dissolution testing there are often multiple dissolution baths, anywhere from six to eight. With automation, you can do all filtrations in multiple baths simultaneously.

JK: The main challenge with manual testing is repeatability. This process is often performed by different individuals and each person will use different force to press the sample through the syringe filter and take different amounts of time for this processing step. Whether this will have a significant impact on the result or be a significant source of error can vary, but removing the possibility of introducing this source of error is important to consider when developing your filtration method.

High-throughput laboratories tend to use a lot of syringe filters. Do you have any solutions to reuse plastic or improve the sustainability of the process?

DM: If you are using a very small filter and you're only getting limited material through it, and therefore, you're using multiple filters, I would potentially look at something with a pre-filter if viable for your work, or move to a larger diameter size. If you can use a larger diameter filter, you might be able to cut down on the number of filters you are using, and, therefore, you are going to save on the reduced plastics.

Cytiva also have filtration device recycling programs in seven countries in the world. We've partnered with an outside recycler and depending on what is being used, hazardous chemicals or non-hazardous, we have ways that we can help you recycle those filters. If there's any interest in that in your laboratory, I would contact Cytiva and a local representative would be able to walk you through your options.

What tools does Cytiva have in place to facilitate the choice of filter?

DM: Cytiva has an extremely broad portfolio of filters with many choices of membranes. Finding a membrane that is optimal for your test can be daunting. To help with this, Cytiva have the Whatman™ Filter Selector tool. This tool helps you make sure that what you need the filter to do is compatible with the materials that you are working with. The Whatman™ Filter Selector tool will easily walk you through which filter is optimal for your sample type and application in a decision tree-style format.

Learn more about selecting the right type of filtration in this on-demand roundtable discussion>>