Froilabo products for the food and drink industry

Explore how Froilabo’s range of ultra-low temperature (ULT) equipment can help ensure product quality and safety within the food industry

10 Nov 2021

The food industry is subject to increasingly strict regulations. Freezers from Froilabo are manufactured to meet food safety legislation enabling users to track data with complete confidence. Froilabo’s ultra-low temperature (ULT) equipment is manufactured under ISO 9001 and ISO 13485 standards.

This article provides an overview of Froilabo’s products which are beneficial for those working in the food and drink industry.

Applications of ultra-low temperature freezers for the food and drink industry

An ultra-low temperature (ULT) freezer typically has a temperature range of -45°C to -86°C and is usually used for the storage of drugs, enzymes, chemicals, bacteria, and other samples. ULT freezers are also required for a range of different applications within the food and drink industry.

1. Freezing fish at ultra-low temperatures

It is becoming increasingly common for chefs in restaurants to use ULT freezers for deep freezing fish. This includes general fish such as cod or hake, as well as more specialist fish dishes including sushi.

It is estimated that the water content of raw fish is around 70% and when frozen, these molecules of water turn into crystals. In a conventional freezer (around -18°C), this crystallization process can take long periods of time, during which more crystals join together to form larger crystals which can often puncture the cells of the flesh. An increased amount of liquid will therefore be released when it is eventually defrosted which has a negative effect on the texture of the fish.

By using a ULT freezer instead, the fish is frozen at a much faster speed, minimizing the crystallization process and avoiding the risk of puncturing the cells. As a result, this preserves the original texture of the fish and leads to improved taste when the fish is defrosted for consumption.

2. Storing fish at ultra-low temperatures

When shipping and storing fish or any other type of food product, the method of freezing can be a significant influence on how the finished product tastes and looks. Fish can be stored in a ULT freezer between -40°C to -60°C, which helps to preserve the organoleptic qualities of the flesh and allows storage for much longer periods of time.

Fish such as plaice and sole can be stored for 9 months at -18°C, but can be stored for 2 years if frozen at -30°C. This benefits restaurants as it allows them to better manage their supply chains as they can bulk buy or stockpile certain types of fish at different times of the year when supply is good, ensuring a good supply of all types of fish all year round.

Froilabo’s Ultra-Low Temperature Freezers

At Froilabo, we offer a wide range of both ultra-low and low-temperature freezers, reaching -86°C and guaranteeing maximum protection of samples in all circumstances. Our freezers have capacities ranging from 175 liters up to 1,000 liters.

With unbeatable value for money, the Trust low-temperature range of freezers is ideal for long-term sample storage. The proposed volumes range from 340 to 690L.

Ideal for everyday use with regular door openings, the Evolution range offers many innovative solutions to ensure the safety of your samples and simplify your life. The proposed volumes range from 340 to 690L.

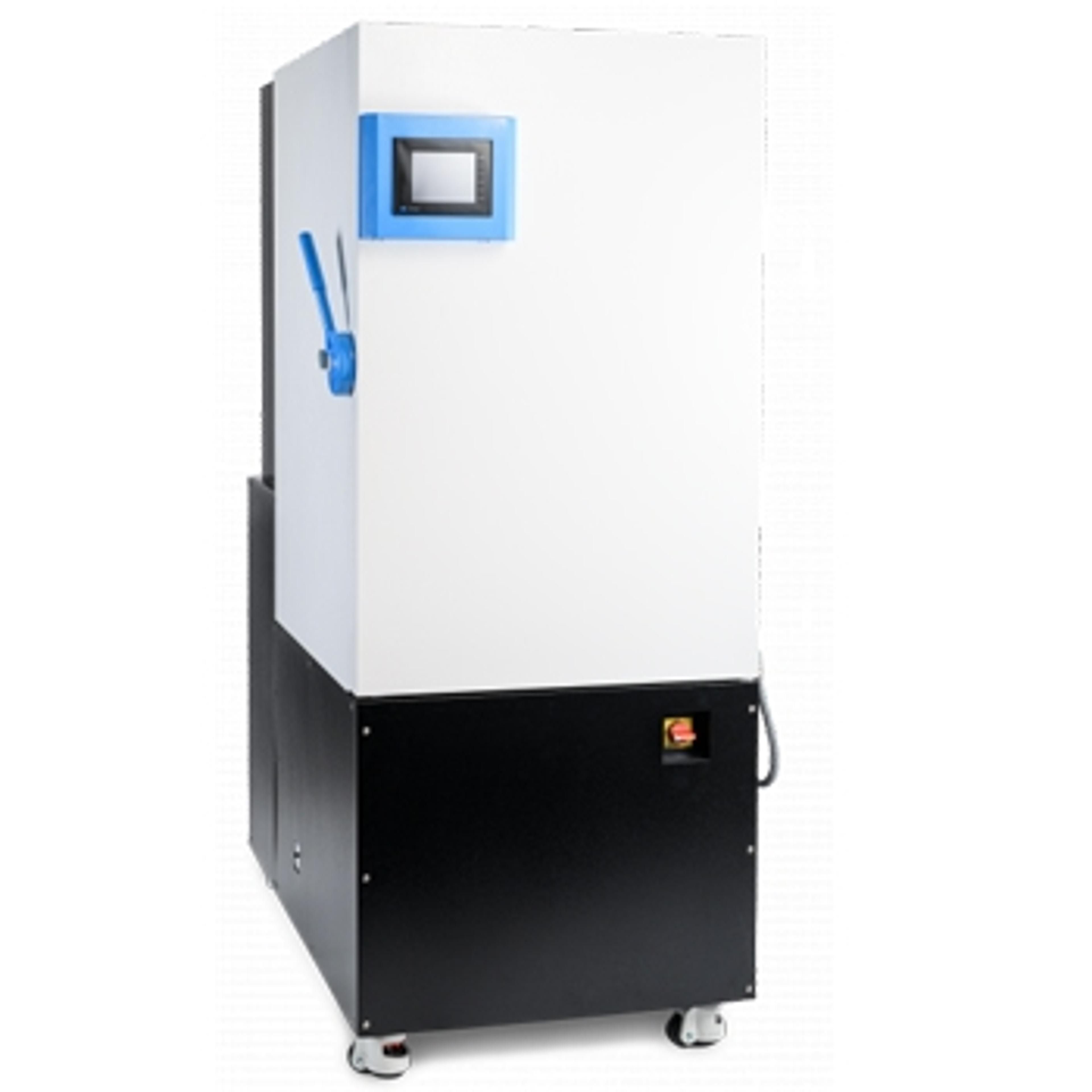

The BM/BMT ranges are available in 2 volumes: 175L and 1000L. The unique design of these devices delivers unparalleled reliability and performance. These ranges are available with standard controller (BM) and touch screen (BMT).

The BMH range of Froilabo horizontal freezers are designed on the same basis as the BM range and are available in 3 volumes.

Applications of Blast Freezers for the food and drink industry

A blast freezer, which is also known as a shock freezer, is designed to very rapidly bring down the temperature of the contents being stored. Blast freezers are used for a range of applications in the food industry, including in commercial kitchens and for fresh produce, ice cream, pre-prepared meals, and vegetables or fish.

Current food legislation requires that all food must be cooled as quickly as possible, which means that whenever food is frozen, it must be in the ‘Danger Zone’ for as little time as possible, which is between +8ºC and +68ºC where bacteria multiply fastest. The much lower temperature allows for a longer shelf life, as blast freezers can store food for up to 18 months, depending on the type of food and ingredients. A standard freezer can store frozen products for an average of just 3 months.

Blast freezing is one of the most versatile methods of food preservation, and for seafood, blast freezing provides a level of taste, texture and presentation unlike any other method. This is due to the speed at which the product is frozen, with the process involving pushing cold air across the produce at a very high velocity and a very low temperature.

1. Agriculture

Blast freezers have been revolutionary for the agricultural industry, as farmers are no longer limited to only selling seasonal varieties of produce. By using the process of blast freezing, seasonal fruits and vegetables can be sold year-round, which prevents food wastage and the over-growing of crops.

2. Meat and fish

Fresh meats and fish especially run the risk of containing a large amount of bacteria and microbial residue. From oily fish such as mackerel to hardier meats, a blast freezer can help to extend shelf life substantially whilst not compromising on flavor or safety.

For seafood, blast freezing provides a level of taste, texture and presentation unlike any other method. The high water content, which can be anywhere from 60 to 80% water, makes it especially susceptible to the cell-damaging parts of the freezing process.

3. Restaurants

The use of blast freezers is very common in restaurants. Blast freezing of meat and fish allows cooks to make use of seasonal produce throughout the year, meaning that they can significantly cut costs by stockpiling produce and buying in bulk.

Certain high-end restaurants use blast freezers to prepare ultra-smooth ice cream and sorbets. The fast freezing process ensures that smaller ice crystals translate into smooth creamy textures that melt in your mouth and bring out the sweetness and flavour.

4. Sushi

Many restaurants freeze clams, oysters and mussels and then allow them to cool in the refrigerator. The Japanese have been using blast freezers for years to preserve the quality of freshly caught fish for making sushi, because it maintains its quality and texture so well.

5. Commercial Catering

Poor quality food can be highly damaging to catering businesses and reputations. Many catering companies therefore use blast freezers because they allow the freezing of larger volumes of food at a much quicker rate than when using a conventional freezer, saving time and money. They often prepare food at a central production unit, before blast freezing it for transport.

Blast freezing products is ideal for transportation and moving to other locations for regeneration, and is often used for transporting food to airlines, prisons and schools.

6. Bakeries

Industrial-scale bakeries use blast freezers to cool butter-rich doughs to help reduce the wait time between mixing, shaping, and then baking. They are useful for quickly cooling down baked goods after they have come out of the oven. This helps the food to retain the crisp texture of the crusts and allows them to be eaten at their optimal temperature.

Blast freezing of finished products also helps large bakeries to better prepare for unusual high demand peaks, by preserving produce and stockpiling to store and sell at a later date. This is also beneficial for transportation and storage from factories to external bakeries, where they can be proofed and baked.

Froilabo’s Blast Freezer

At Froilabo, our blast freezer (CRP100) performs a fast, homogenous and reproducible temperature drop that is suitable for a wide range of applications. The CRP100 is available in a single volume, 270L, and is suitable for the fast freezing of a variety of food and medical products used within a laboratory. It has the capacity to freeze 100 bags of 280mL and the different versions available (water condenser, remote air condenser, remote cooling unit) allow adaptation to installation premises as well as usage constraints.

Froilabo blast freezers guarantee a fast temperature drop and can reach -11°C in 60 minutes and -30°C in less than 90 minutes.

The product has an intuitive interface with a colored touch screen installed on the door. This screen allows the user to manage the programming as well as the visualization of the temperatures, the time taken, and the current freezing cycle.

The operating temperatures are tracked and displayed continuously. At the end of the freezing cycle, a color code efficiently displays how the cycle went. Products can be loaded quickly and safely with a trolley on wheels. Once the freezing cycle is complete, the cart can be taken out and emptied without coming into direct contact with cold parts and therefore avoiding the risk of burning due to the cold.

Learn more about the Froilabo CRP100 Blast Freezer today.

For more of the latest science news, straight to your inbox, become a member of SelectScience for free today>>