From explosive detection to routine analysis & biological research: The evolution of the ion mobility spectrometer

With near 30 years dedicated to the advancement of IMS, Excellims founder Dr. Ching Wu shares the story behind the first high-performance systems

23 Sept 2020

Excellims founder and CEO, Dr. Ching Wu is a man on a mission. In this exclusive interview, we sit down with this pioneer of ion mobility spectrometry (IMS) technology, to find out more about the journey that took him from the security industry to the very frontline of scientific advancement.

Before setting up Excellims in 2005, Dr. Wu served as a research leader for GE Security’s Chem/Bio Center of Excellence, where he worked closely with government agencies and provided many IMS-based solutions that are vital throughout critical chemical and explosive detection fields, including the airport security screening we all know today. Excellims initially came to fruition as a technology development company for the security sector, acting in a similar way to an academic group working on a research contract basis.

Dr. Wu led a team that built on his research interests from his graduate study to advance IMS and mass spectrometry (MS) technology and develop cutting-edge instrumentation. In addressing the key challenges within the security sector, Dr. Wu and his team realized the commonalities with other applied markets, including the ever-increasing demand for high-quality QC in the pharmaceutical industry. Since then, Excellims has been revolutionizing IMS systems for a range of applications and has rapidly evolved into the advanced instrument manufacturer it is today.

How has Excellims and the industry changed over the past 15 years?

CW: Ion mobility instruments began to move from a handheld in-situ detection device for chemical warfare agents to the common research lab in the mid to late 2000s. Not long after this, we started showing researchers how combining IMS with MS technology can be used for biological sample analysis with high resolution and orthogonality to mass spectrometry. Now, every mass spec company has hyphenated ion mobility instruments, and its applications are being expanded to omics research and other fields where MS is commonly used. Excellims’ HPIMS technology has not only been used to enhance MS performance in the laboratory environments, but also emphasized in moving the laboratory analytical capability to where the chemical analysis is needed, such as in chemical and pharma, food and beverage, petrochemical, and other such markets – that’s where we focus our innovative efforts today.

What are the key challenges with analytical and separation technology?

CW: Within life science applications, particularly for human samples, we’re seeing the sample getting more and more complex. No matter what complex sample you are analyzing, you are looking to quantify those target molecules among millions of others. This requires analytical technology that can separate the targeted compound from the others. Traditional liquid or gas chromatography combined with mass spec has limitations on resolution – our technology fixes this. These traditional technologies are separating molecules based on the molecular polarity or weight of the molecule. However, IMS can separate molecules from a different angle, the molecular size (collisional cross-section) which gives you another powerful tool to separate molecules in a complex mixture.

High-performance IMS in the field

Another aspect to consider is that many of the traditional high-performance analytical instruments are lab-scale instruments. They are cumbersome when trying to take a measurement in the field and are often fixed to one research site only. A key strength of Excellims is that it is now able to bring the laboratory instrument to where the measurement is needed, the point of analysis, with Excellims’ GA and MC series of instruments.

Clearly a higher performance instrument was needed in the field. That’s why we developed the high-performance ion mobility spectrometer - we’ve set the industrial standard for the commercial fieldable IMS for point-of-analysis type of instrument.

Dr. Ching Wu Founder & CEO of Excellims

Quick and easy chemical analysis

Excellims is currently offering three high-performance ion mobility spectrometers (HPIMS). The first of these is its GA2200, a standalone HPIMS which incorporates an electrospray ionization source. It features a superior resolving power (70+) to more traditional IMS systems, and, with the electrospray ionization, it can be used to analyze non-volatiles and large organic molecules within a sample. Excellims has seen great success within pharmaceutical quality control, for example, in the cleaning verification process. This can be attributed to the GA2200’s reduced sample analysis time, from around 12 minutes per sample with typical HPLC systems to less than a minute per sample.

The second addition to its lineup, the MA3100, involves a collaboration with Thermo Fisher Scientific to deliver an HPIMS that incorporates the Orbitrap Mass Spectrometer. This paired system allows you to pre-separate the sample mixture in the ion mobility spectrometer, and then put it into the mass spectrometer to do your routine study. Or, you can combine this IMS operation with mass spec through a linked scan operation mode and identify every molecule in the mixture based on two properties. One is the molecular size and shape, and the other one is the molecular weight, so it becomes a powerful research tool in the place of traditional HPLC-MS.

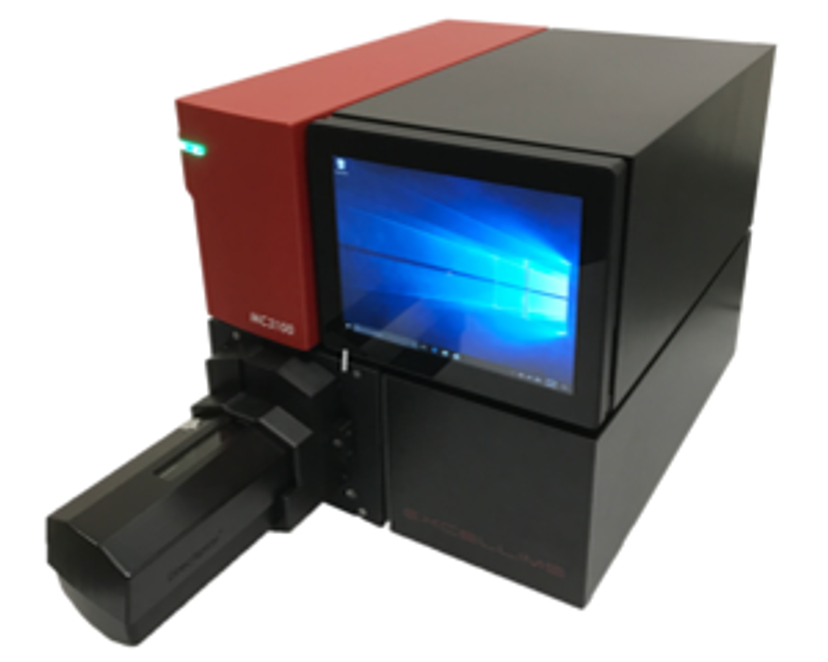

Excellims’ third and most recent product, the MC3100, is the first compact IMS-MS available to the market. This small benchtop system promises to provide access to the same breakthrough IMS technology found in the HPIMS-Orbitrap MS system and its laboratory-level performance mass analyzer, enabling high performance and two-dimensional chemical identification at the point of analysis. The new tool can be used at the chemical research bench, on the pharmaceutical manufacturing floor, as well as for point-of-care clinical diagnostics.

What do you see for Excellims in the future?

CW: I think the future for the company will focus on point-of-analysis instruments, a term that we created. We want to bring the laboratory performance instrument into the field – that’s the overall goal. In terms of the application areas, we are really focusing on the pharmaceutical and chemical manufacturing process, as these industries are really adopting our technology. Of course, we will continue to advance our well-established technology in the security sectors, enabling them to reduce the false alarm rate and achieve better detection. A very new area we are pushing into is medical diagnostics. In this field, there are strict regulatory requirements, as you are now dealing with human samples, so the goal is to identify chemicals and biomarkers in those complex samples and develop IMS applications for patient diagnostics.

Do you use Excellims' products in your lab? Write a review for your chance to win a $400 Amazon gift card>>