Fume cupboard technology as a combination of resource conservation, cost reduction and safety

23 May 2023

Laboratories provide a controlled environment for experimentation and analysis. Working safely is the top priority here to protect laboratory staff. But another focus of laboratory service providers and companies is now on sustainable operations. Is it possible to design, plan and operate laboratory environments that are both safe and sustainable?

The results of research work and processes are ultimately sustainable. After all, they form the basis of all developments. Innovations - like the sustainability of the future - are created through experimentation, and laboratories provide the space that enables this in practice. But in terms of work and consumption, laboratories use considerable amounts of energy and resources. Waste is produced and materials are used that can have a negative impact on the environment. Although the services provided here are indispensable, the facilities are increasingly subject to sustainability audits. Particular attention is paid to the materials and equipment used. Products are considered sustainable if they use resources responsibly, save costs and offer safety. Starting with the raw materials, continuing with the production and use phase and ending with disposal. The effects on the environment and economic efficiency are considered over the entire life cycle.

Energy consumption for safety and future

What about the energy used in laboratories? It is conceivable that laboratory work requires a lot of electricity. Nevertheless, the average electricity consumption for a single microbiology laboratory calculated by the University of Natural Resources and Applied Life Sciences in Vienna is an impressive figure. Around 228,000 kilowatt hours per year are consumed here1. This is 65 times the average yearly power consumption of a single-family house with four people. Harvard University has taken a closer look: Their research rooms occupy about a fifth of the space, but consume almost half of the total energy. 44 per cent of this is directly related to ventilation, which in turn is significantly influenced by the fume cupboards.

This once again enclosed working space in the laboratory room is essential for the safe use of volatile organic compounds, acids or solvents.2 However, these devices in particular draw conditioned air from the laboratory, the treatment of which is energy-intensive and thus expensive as well as environmentally harmful. It is therefore important to pay particular attention to the ecological and economic effects of fume cupboards.

Tested safety

The topic of sustainability can also be viewed in terms of a social component: Responsibility towards people. This results in the core requirement of fume cupboards, safety. Fume cupboards must protect people during their daily work in the laboratory. To this end, three protection goals are defined in the professional association guidelines and the European fume cupboard standard (EN 14175 Part 2): "Fume cupboards must be designed in such a way that, due to their construction and air ducting, in the operating condition

- gases, vapours or dusts in dangerous concentrations or quantities cannot enter the laboratory from inside the fume cupboard,

- no dangerous explosive atmosphere can form inside the fume cupboard and

- insured persons are protected against splashing hazardous substances or flying glass fragments".3

Two components must be considered with regard to the retention capacity of the fume cupboard - described in the first paragraph of the fume cupboard standard: The structural design of the fume cupboard and its required exhaust air volume. If the constructional design is fixed, the empirical formula applies: The larger the exhaust air volume, the better the retention capacity, the safer the fume cupboard. Thus, economy and safety are inversely proportional to each other: Higher safety is achieved through higher operating costs.

Reducing air consumption while maintaining safe working conditions is thus one of the most important requirements in the development of fume cupboards. The power consumption of a fume cupboard operated at maximum level with the sash open can reach a sum equivalent to the operation of three houses combined - calculated by Evan Mills and Dale Sartor of Lawrence Berkeley National Laboratory.4

Saving energy with the sash

Exhaust air control systems are the keyword for fume cupboards in terms of power consumption, because they reduce the exhaust air flow when the sash is closed without jeopardising the safety of the fume cupboard. The exhaust air volume flow is controlled by a motor-driven damper depending on the sash opening. For each operating state of the fume cupboard, just as much air is extracted from the laboratory as is necessary for the safe operation of the fume cupboard. With the sash closed, the volume flow of a fume cupboard can be reduced by around 50 percent compared to the open state. With Köttermann fume cupboards, the sash opening is effortlessly adjusted via the TouchTronic electronic control unit using the controller on the display - precisely by sliding or selectively by tapping.

The automatic protection mechanism EXPLORIS AutoProtect® automatically closes the sash as soon as the work in the fume cupboard ends. This saves energy and at the same time minimises the potential danger. If something should ever protrude from the fume cupboard, EXPLORIS CloseGuard® uses a light grid to ensure that the sash stops automatically.

A fume cupboard as a sustainability ace

In addition to the sash position, the reduction of operating costs while complying with safety requirements can be achieved by a well thought-out product design. An example of this is the Köttermann fume cupboard EXPLORIS EcoPlus®, which requires a low air volume flow due to a special air technology and design.

With a recommended constant volume flow of 275 m³/h per metre of fume cupboard width, the EXPLORIS EcoPlus® consumes an exhaust air volume that is about 30 percent less than a standard fume cupboard on the market. This saves up to 1,000 euros in operating costs per year. Especially on the basis of energy savings without the installation of exhaust air controls, the EcoPlus® is the ideal choice for laboratories.

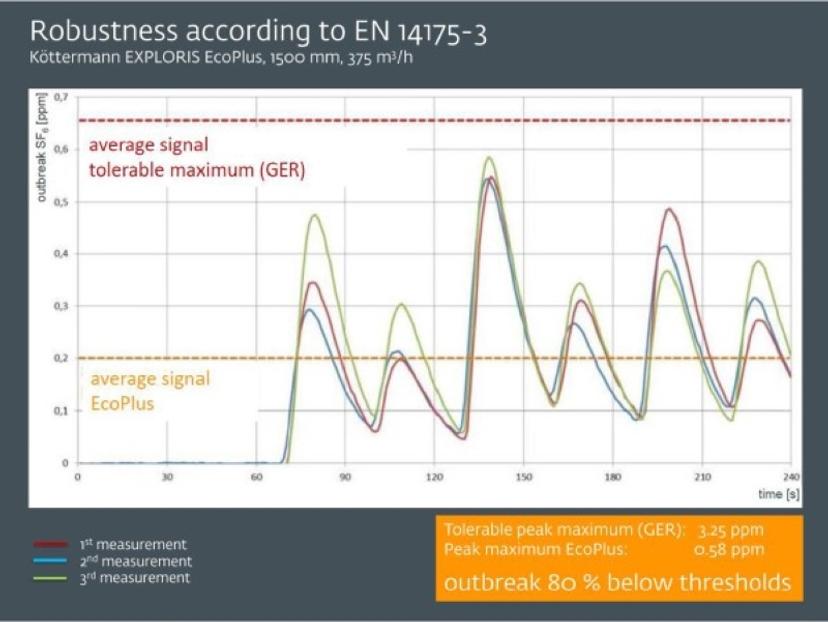

The core of the EcoPlus® is its unique flow technology: This reduces the air volume flow while simultaneously meeting all safety requirements. The standard is correspondingly high: in the robustness test for evaluating the performance of fume cupboards, the test gas burst of the EcoPlus® is 70 percent below the limit value for fume cupboards required by the BG RCI.

In summary - as stated in the fume cupboard standard in the second and third paragraph - a fume cupboard is considered safe if it corresponds to the state of the art, has been tested according to existing standards and complies with the prescribed limit values with large safety reserves. In practical laboratory use, the fume cupboard is always part of a process chain. Its safety is determined by many parameters that are influenced not only by the design of the fume cupboard but also by its use. Examples of these are:

- Is the air flow of the fume cupboard disturbed by external influences at the installation site?

The greater the danger from the processes carried out in the fume cupboard, the more important it is that the airflow is not influenced by people passing by or draughts in the laboratory.

- Who works on the fume cupboard? Is the staff sufficiently experienced to be able to carry out the work without danger?

- Are there operating instructions and do the employees live by them in everyday life?

- How is the handling e.g. storage and disposal of hazardous substances organized?

- What emergency measures are setup in case of spillage of chemicals ore accidents?

Therefore, the fume cupboard is always a centrepiece of a safe and sustainable working environment, but it must be accommodated with other essential and safety-related features in the laboratory like eye-showers or safety cabinets for flammable chemicals.

It all depends on the material

Laboratory fume cupboards on the one hand and the type of laboratory furniture on the other hand are the basis of occupational safety for laboratory staff. Short and ergonomically planned paths, sufficient work surfaces and safe storage space are one important factor, another is the material of the furniture. Here, Köttermann's steel furniture produced in Germany has a clear advantage: steel is durable, long-lasting, water-repellent and easy to clean.

In terms of sustainability, steel is 100 per cent recyclable. In every recycling stage, the properties are retained while the quality remains the same. Even multi-recycling capability can be attributed to the material, because steel can be recycled over several life cycles and thus saves 50 percent of the original CO2 emissions.

References

1. Source: https://greenlabsaustria.at/. 27/04/2023

2. Source: Quentin Gilly: Validating cost and energy savings from Harvard's shut the sash program. In: https://green.harvard.edu/sites/green.harvard.edu/files/FumeHoodWhitePaper.pdf. 27/04/2023

3. Source: Deutsche Gesetzliche Unfallversicherung (DGUV): Handlungshilfen. Working Safely in Laboratories Basic Principles and Guidelines. 04/2017. p. 142. https://downloadcenter.bgrci.de/resource/downloadcenter/downloads/DGUV-Information_213-851_Gesamtdokument.pdf. 27/04/202

4. Source: Mills and Sartor: Energy Volume 30, Issue 10, July 2005, Pages 1859- 1864