Get The Best Out of Your Centrifuge

Find out all you need to know to keep this essential piece of kit running efficiently and effectively, and avoid unnecessary difficulties in your laboratory

12 Feb 2018Centrifuges are fundamental components of life science and clinical laboratories. Reccurring operational errors and repair costs take away valuable time and budget from research. While some maintenance procedures require experienced technicians and third-party services, there is a lot that users can do to maintain centrifuge performance.

In this article, we look at the top tips to help maintain your centrifuge and help extend its efficiency and lifespan.

Centrifuges are high-precision, high-speed instruments. This is vital for proper function, but leaves the equipment with some inherant vulnerabilities to dirt, dust and particulates that can lead to abrasion and wearing of rotating parts.

If left unchecked, this can:

- Cause damage to your centrifuge that can result in equipment failure over time and shorten its effective lifespan

- Reduce processing capacity due to non-functional equipment

- Present a hazard to health: failure in the lid spring mechanism could allow the cover to slam closed, and harm the user; it may also be possible to accidentally open the centrifuge when in operation

- Lead to breaks in tubes and the potential release of biohazardous or radioactive substances

Inspection for signs of damage or wear

When inactive, look over the entire centrifuge for:

- Wear, corrosion or pitting of parts that may require replacing

- Physical damage, including surface scratches or cracks

- Current lifecycle counts vs. maximum for the centrifuge

Indications of potential problems during use:

- Shaking of the centrifuge suggests an unbalanced load, problems with the buckets or trunnions, or shock absorber issues

- The sound of air being released could indicate a break in the lid gasket

- Buckets that don’t swing up correctly might indicate the need for lubrication or a mechanical issue

- Discharge of unusual or oily substances during operation is a sign of either improper lubrication or a leak

- Failure to operate or achieve full operating speed is also a clear warning sign

In the event of any of these issues during operation, you should:

- Shut down the centrifuge to avoid damage to the equipment

- Contact the lab or equipment manager

- Arrange an immediate repair

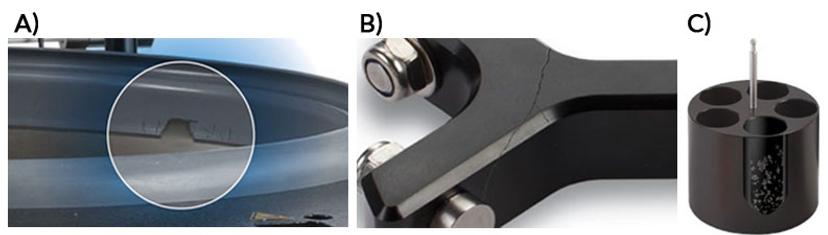

A) Damage to lid gasket; B) Crack in a centrifuge rotor; C) Corrosion in a hard-to-see area

Regular cleaning and lubrication

Cleaning

When inactive, follow this process:

- First, check what cleaning materials are appropriate for your model

- Consider decontamination steps if the centrifuge has been used with biohazards or radioactive samples

- If your centrifuge is temperature controlling, depending on the kind of heat exchange used, there may be surfaces that should be wiped to remove dust and dirt and allow more efficient transfer of heat

Lubrication

Regular lubrication allows components to move unhindered, reducing friction, increasing performance, and minimizing the potential for damage from ordinary operation. When lubricating your centrifuge, you should consider:

- Lubricants appropriate for your model

- The frequency of lubrication required

- Common components in need of lubrication, such as the drive shaft and buckets/trunnions

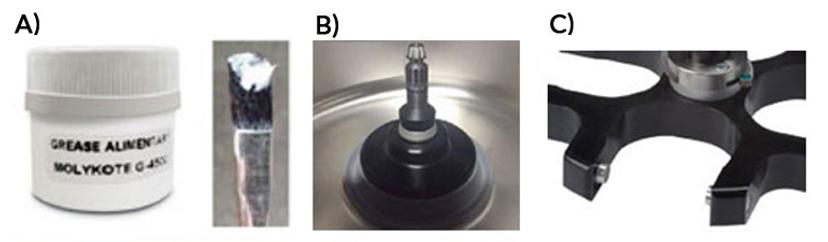

A) Lubricant; B) Drive shaft; C) Buckets/trunnions

Create a maintenance culture

In addition to creating and implementing a maintenance plan in your lab, a strong maintenance culture helps ensure effective equipment.

- Education - users should be made aware that maintenance tasks are a fundamental part of running a laboratory and should not be considered a distraction from their work.

- Training - proper training expands on education and includes demonstrations and follow-up sessions to strengthen users’ skills and validate processes.

- Maintenance schedule - keep work interruptions to a minimum by establishing a schedule for performing maintenance tasks.

- Maintenance logs - record maintenance tasks and note duty cycles: this will become important in managing overall maintenance and ensuring tasks are completed to schedule.

Ultimately, ongoing maintenance is a minor burden when done correctly, and a boon for budgets because machines run efficiently and effectively for longer.

Do you use NuAire products in your laboratory? Write a Review Today for the Chance to Win in our 12 Reviews of Christmas Competiton