How to achieve the Lab of the Future with expert insights from industry, academia, and manufacturing

Explore how experts from three different sectors envision the Lab of the Future and gain insights and strategies to stay ahead in an ever-changing scientific world

31 Oct 2023

The vision of the Lab of the Future (LoF) encompasses the evolution of labs into highly advanced, digitally integrated, and more efficient spaces for scientific research. This transformative shift is expected to enable scientists to maximize productivity and data quality, and ultimately enhance scientific innovation. Nevertheless, realizing the full potential of the LoF is not without its challenges, and labs must proactively adapt to the ever-changing landscape of scientific research and technology.

In this article, three experts across biopharma, academia, and manufacturing provide a comprehensive overview of the LoF concept, exploring its potential impact on various sectors, the challenges involved, and the critical steps that labs must take to align themselves with this transformative vision.

(L to R): Dr. Matthias Zimmermann (Executive Director of Bioprocess Development at CSL), Dr. Joshua Kangas, (Assistant Teaching Professor and Co-Director of the M.S. Automated Science Program at the Computational Biology Department of Carnegie Mellon University), and Dr. Hansjoerg Haas, (Senior Director and General Manager of Laboratory Automation at Thermo Fisher Scientific) share their thoughts on LoF.

What the LoF looks like

The LoF is inherently flexible and adaptable, there is no rigid blueprint that prescribes a one-size-fits-all model. Instead, it embraces the idea that each lab will have unique requirements when it comes to the optimal setup, and what works for one organization may not necessarily work for another.

“The LoF represents an innovative transformation from traditional labs into more efficient, automated, and data-driven facilities,” summarises Dr. Hansjoerg Haas, Senior Director and General Manager of Laboratory Automation at Thermo Fisher Scientific. “LoF will entail a holistic approach with key elements that work together to create a connected and intelligent research environment.”

Key LoF components include:

- Automation and robotics to reduce manual tasks and enhance accuracy

- Internet of Things (IoT) devices for real-time data collection and process optimization

- Artificial intelligence (AI) and machine learning (ML) for data analysis and decision support

- Cloud computing for collaborative data access

- Augmented (AR) and virtual reality (VR) tools for training and equipment interaction

- Sustainable practices to reduce waste and environmental impact

While the LoF is designed to drive workflow efficiency and accelerate scientific advancement, Haas points out the considerations this transformation needs in terms of safety and security. “AI and ML insights will play a significant role in transforming lab operations and they are already proving valuable in aiding decision-making and assisting with data analysis, pattern recognition, experiment planning, and suggesting new steps,” says Haas. “However, the increasing digitization of lab processes also increases vulnerability to cybersecurity threats. Therefore, controlling accessibility and authorization is crucial and security measures must be put in place to safeguard sensitive data and operations effectively.”

“LoF represents an innovative transformation of traditional labs into more efficient, automated, and data-driven spaces.” Dr. Hansjoerg Haas, Thermo Fisher Scientific

Importance of an integrated ecosystem in the biopharma LoF

Striving for a LoF is of particular importance for the biopharma industry. The formidable challenges posed by highly complex drug candidates and the industry shift towards personalized treatments requires confident and timely handling of vast and intricate data sets. Additionally, LoF components are paramount to achieving cost-efficiency, speed, regulatory compliance, and scalability in drug discovery and development.

“Our pipeline is witnessing robust growth both in volume and complexity, as we anticipate launching numerous drug candidates across diverse modalities in the upcoming years,” shares Dr. Matthias Zimmermann, Executive Director of Bioprocess Development, CSL, Australia. “This pipeline expansion comes with an unequivocal expectation to streamline project delivery in the future.”

In 2020, CSL launched its BPD2030 Innovation framework, which includes a LoF initiative that focuses on advancing data and technology. The team at CSL has also laid the groundwork for its LoF with a paperless lab and manufacturing ecosystem which it aims to integrate into clinical manufacturing and release testing by mid-2024. These initiatives aim to increase digital workforce equivalents (DWE), amplify full-time equivalents (FTEs), simplify processes, optimize costs, reduce time to results, and ultimately accelerate innovative drug delivery to patients with severe medical conditions.

“I envision the biopharma LoF will involve an integrated ecosystem where internal cloud labs are supplemented by external resources,” shares Zimmerman. “Our journey began with the introduction of robotic lab automation for high-throughput processes, as well as the launch of digital skill-enhancing programs. Currently, the analytical robotic system has already cut down FTE time by over threefold and by 2025 I aim for our DWE to double our FTE figures, targeting a quadruple increase by 2030.”

“I envision the biopharma LoF will involve an integrated ecosystem where internal cloud labs are supplemented by external resources.” Dr. Matthias Zimmerman, CSL

LoF requires robust computation

In line with the highly automated and data-driven future of science, the M.S. Automated Science Program at Carnegie Mellon University is primarily focused on preparing the next generation of scientists to thrive in the LoF.

Dr. Joshua Kangas, Assistant Teaching Professor and Co-Director of the M.S. in Automated Science Program at the Computational Biology Department of Carnegie Mellon University, emphasizes the importance of incorporating computational and ML training into the program, as these skills are increasingly essential for understanding large complex datasets generated by automated processes.

The Automated Science Program in the Computational Biology Department of Carnegie Mellon University is designed to train students to use robotics, ML, and AI to generate, analyze, and interpret data effectively.

“Robotics, AI, and automation all contribute to the improvement and advancement of complex and large-scale research scientific research,” says Kangas. “However, these tools can also generate enormous data sets that require computation to be able to understand what's happening. Consequently, computation needs to be considered from the very beginning.”

A significant challenge for the program is establishing the necessary digital infrastructure for data transfer when creating automated science pipelines. Kangas points out that while the industry is improving its data management practices, these systems were not originally designed with the concept of AI-driven experimentation in mind, particularly for education purposes.

"To overcome the challenges of resource limitations in academia, we are launching the CMU Cloud Lab, providing students with remote programmatic access to various hardware for conducting experiments,” shares Kangas, “We have also set up an automation lab in collaboration with Thermo Fisher Scientific that features an integrated robot capable of performing a wide range of tasks that are usually done in undergraduate molecular and cell biology labs.”

Technology’s role in advancing the LoF

With long-standing expertise in the robotics and automation industry, Thermo Fisher Scientific and its products are in a leading position to play a vital role in the journey toward the LoF. For example, Momentum™ Workflow Scheduling Software enables users to define, execute, and monitor scientific processes and workflows in a powerful yet easy-to-use visual environment. Its intuitive scheduling interface, intelligent data-driven decision-making capabilities, superior connectivity, and flexible simulation modes are designed to help achieve new levels of lab automation performance. “The new SmartCart docking solution are a part of the robotic system, and can be used independently, or in conjunction with other robotic platforms, providing the flexibility for customers to quickly adapt automation and use instruments online or offline,” Haas adds. “We are also introducing Autonomous Mobile Robots (AMRs) for material transfer within labs to streamline operations, and an upcoming mobilizer software will also support the scheduling and orchestration of both online and offline resources.

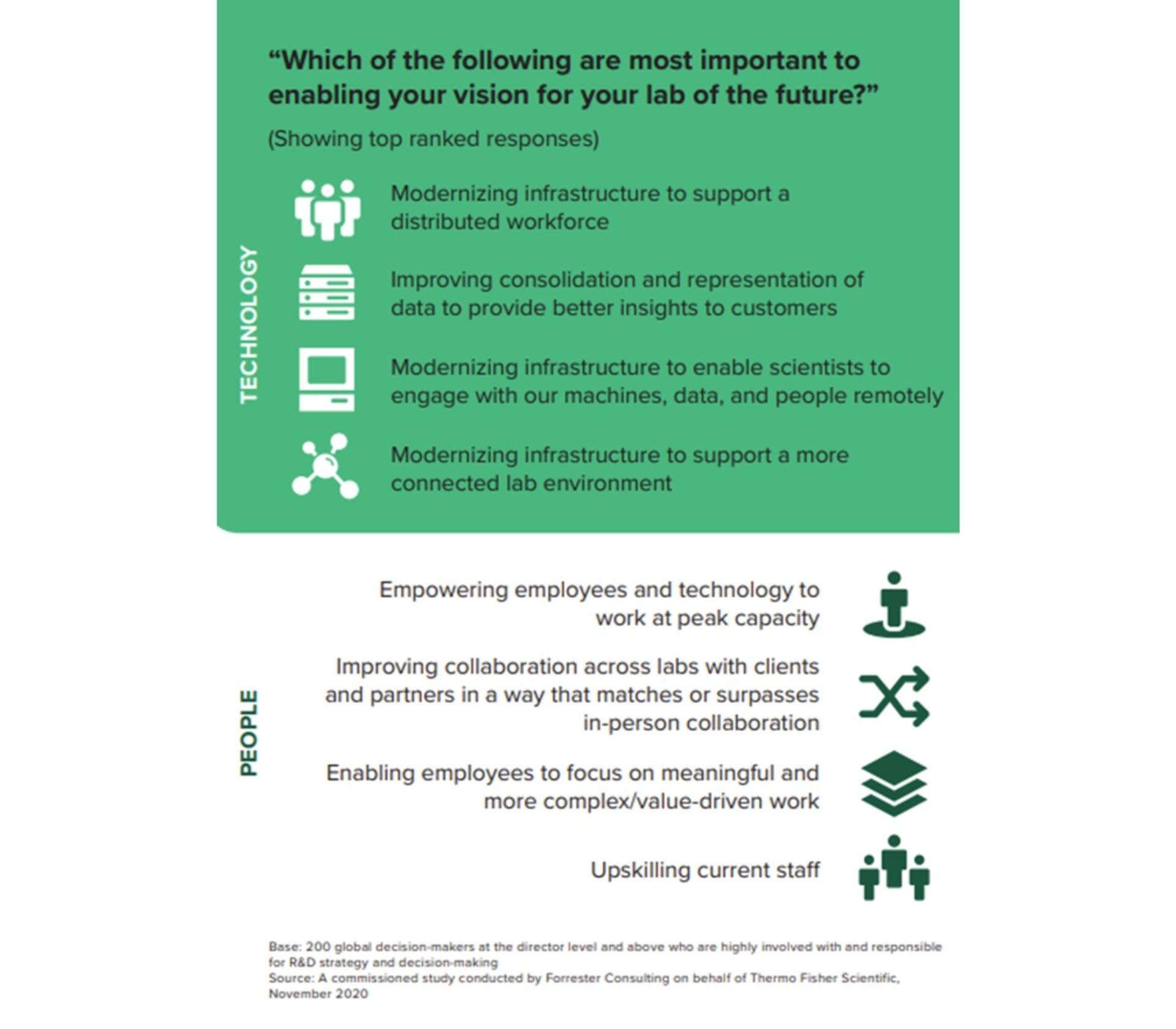

Thermo Fisher Scientific commissioned Forrester Consulting to survey more than 200 executive strategy leaders to explore the Lab of the Future in 2021. Overwhelmingly, they felt finding the right strategic partner to support their integrated strategy is as critical as the hardware and software components.

As well as providing state-of-the-art technology, Thermo Fisher Scientific also serves as a solid industry partner to help organizations progress toward the LoF. Every year, students of the Automated Science Program at Carnegie Mellon University work with Thermo Fisher Scientific on their capstone projects. “This collaboration has proven highly beneficial for the student’s results and fosters a mutually beneficial and ongoing partnership,” says Kangas. “As we are constantly pushing the boundaries of automation, we often seek technical support and ideas from Thermo Fisher Scientific, who are always on hand to offer expert valuable advice.”

Similarly, CSL recognizes Thermo Fisher Scientific’s profound domain expertise and prominent position in the industry and so has selected Thermo Fisher Scientific as a go-to strategic partner for lab automation. “Collaborating with strategic partners like Thermo Fisher Scientific in the digital and automation realms can provide access to specialized expertise and resources,” states Zimmerman. Following collaborative workshops, an automation blueprint was created and initiated and CSL is currently partnering on instrument and software integration projects to ensure seamless sample and data transitions.

Advice for labs looking to become ‘future-ready’

In the ever-evolving landscape of scientific research, labs seeking to maintain their competitiveness and future readiness should consider the following:

“Investing in ongoing development for existing team members and recruiting fresh talent with expertise in lab automation and data science is essential,” shares Zimmerman. “In addition, close engagement with the IT department is crucial to establish robust foundational support.”

Kangas seconds the requirement for highly skilled and specialised personnel. “I would recommend that you hire computational people, perhaps even at the pace that you hire your lab people, and get them involved in experimental planning as early as possible,” advises Kangas. “This ensures the integration of computational thinking into experimental design.” He adds: “My last bit of advice for students specifically is to expect unexpected changes in the field and to embrace continuous learning throughout their careers.”

“Expect unexpected changes in the field and embrace continuous learning throughout [your] careers.” Dr. Joshua Kangas, Carnegie Melon University.

The process of digital transformation in a lab involves three crucial steps:

- Integrate people, equipment, consumables, systems, and data to eliminate siloed data and enable data availability.

- Establish end-to-end workflows using digital technology to optimize processes.

- Implement advanced analytics to allow AI solutions to analyze data and address critical challenges.

Haas concludes: “Labs should be designed with the adaptability to accommodate automation, mobile robotics, with future developments in mind, shifting from a human-centric to an automation-enabled approach. Building a technology stack that allows for scalability and long-term support from vendors is crucial, and processes and procedures must be well-documented, up-to-date, and forward-looking.”

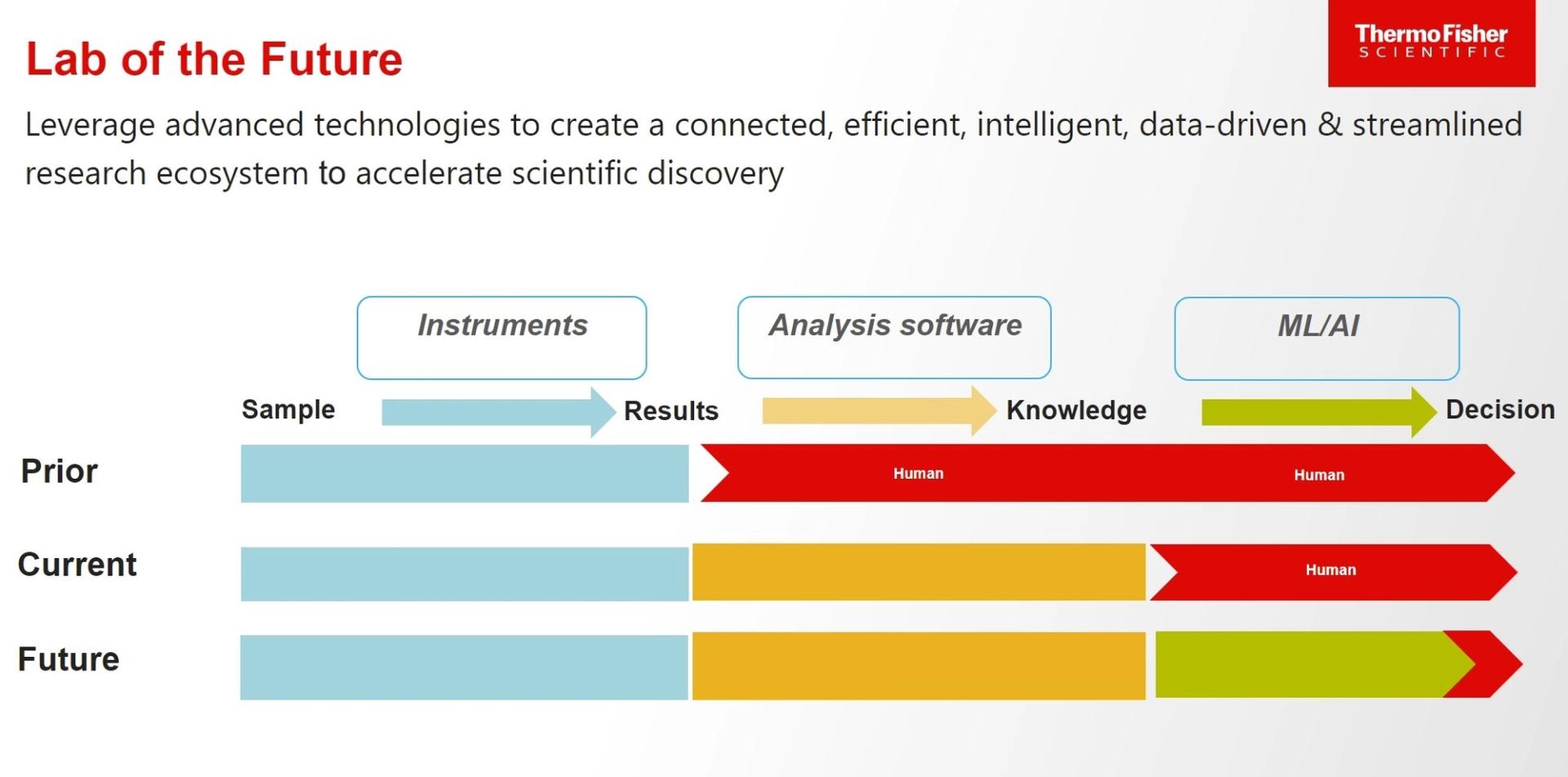

Evolving towards the LoF: Leverage advanced technologies to create a connected, efficient, intelligent, data-driven, and streamlined research ecosystem to accelerate scientific discovery