Innovation in aluminum: How to achieve flexibility and efficiency for global success

Discover the X-ray diffraction system that helps a leading provider of sheet aluminum provide high-quality materials and product advances

26 Apr 2020

Aluminum and its alloys make attractive materials, for use in a range of industries, from packaging to transportation. The inert metal is lightweight, corrosion-resistant, and ductile, as well as being the most abundant metal on earth. As one of the leading suppliers and recyclers of rolled sheet aluminum, Novelis is a company at the forefront of this industry, aiming to provide high-quality products and expand the use of this versatile metal.

In this exclusive interview, we speak with John Ho, an engineer at Novelis, about how the company ensures flexibility and efficiency in its research and strives to offer innovative solutions to its customers across the world.

Q: Tell us a little about your background and the work you do at Novelis

JH: I was originally hired by Novelis as a technologist to run and manage X-ray diffraction (XRD) at our site, but I have expanded my role to include project management, internal quality auditing, and laboratory management of the optical microscopes as well. I now work in the R&D headquarters as an engineer in the Surface Science team, who are responsible for the analysis and research of how our metal’s surface can impact performance on surface aesthetics, coating response, and adhesive performance.

One of my current projects uses line profile analysis of the Empyrean system from Malvern Panalytical to quantitatively measure the dislocation densities within highly strained aluminum, which is difficult to capture with other techniques in a statistical manner. These measurements will allow us to design aluminum sheets for can ends with high strengths without losing formability in the process.

Q: How do you use the Empyrean system in your work?

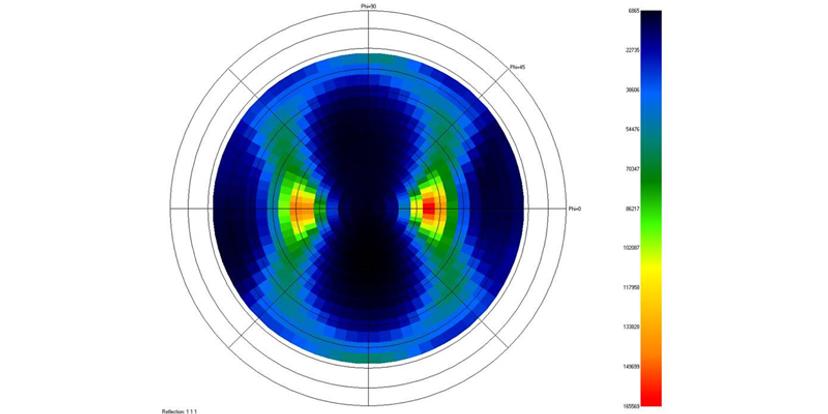

JH: The main application of our Empyrean is to determine the crystallographic texture in our materials, whether as part of new alloy research and development, or as support for our plants to understand an underlying issue on a production material. The XRD measures texture from crystal orientations on a broad area of the surface of a sample and plots the orientations as contours of magnitude on what is described as a pole figure. Several pole figures are measured per sample to account for the many different crystal orientations, and these are analyzed together to give a statistical representation of which crystal orientations are preferred in the material. The Empyrean is one of several characterization instruments we have at our facility. It helps to complement our other analytical tools such that we can provide project managers with information quickly and efficiently, allowing us to be flexible and adaptable in our research.

Q: Would you recommend the Empyrean system?

JH: I have used Malvern Panalytical systems for many years, I believe 12 years now, and I have had great results with them. The systems I used as a student at the Georgia Institute of Technology are still in operation, and the improvements made for the Empyrean have helped make the system more flexible and streamlined. They even reached out to me last year for a one-on-one discussion on how I felt about the system and what I would want to improve on it. This gave me a good sense that they listen and want to listen to their users. They have a good technical team as well, and they are always willing to answer questions I send them. Although the response times can vary, depending on the question, the representatives are always willing to help out. The available service plans can offer prioritized scheduling as well, allowing for next day on-site responses for emergencies in some situations. One of the main reasons I chose to stay with Malvern Panalytical over one of their competitors was the apparent knowledge their technical team had on texture and metals, as many other XRD companies are very focused on the pharmaceutical applications.

Q: What do you see for the future of Novelis’ work in the aluminum industry?

JH: Novelis is the leading supplier of aluminum sheet to the automotive industry, and I see more innovative applications of the metal to be brought out in the future. When Ford introduced a redesign of its best-selling Ford F-150 pickup truck, replacing its steel body panels with lightweight aluminum, Novelis provided the product innovation and technical expertise to increase the amount of aluminum on the vehicle, which ultimately served as the catalyst for greater aluminum adoption in the automotive industry more broadly. I think that type of innovation is what we want to continue to bring – increasing the footprint of what people see aluminum as being capable of. I am hoping to help keep the quality of our material high and to bring new ways of increasing what we can do with what we have.

Learn more from the experts:

- Laser diffraction used to improve coffee flavor and quality >>

- NIRS reveals hidden information about plant-water relationships >>

Do you use Malvern Panalytical products in your lab? Write a review today for your chance to win a $400 Amazon gift card>>