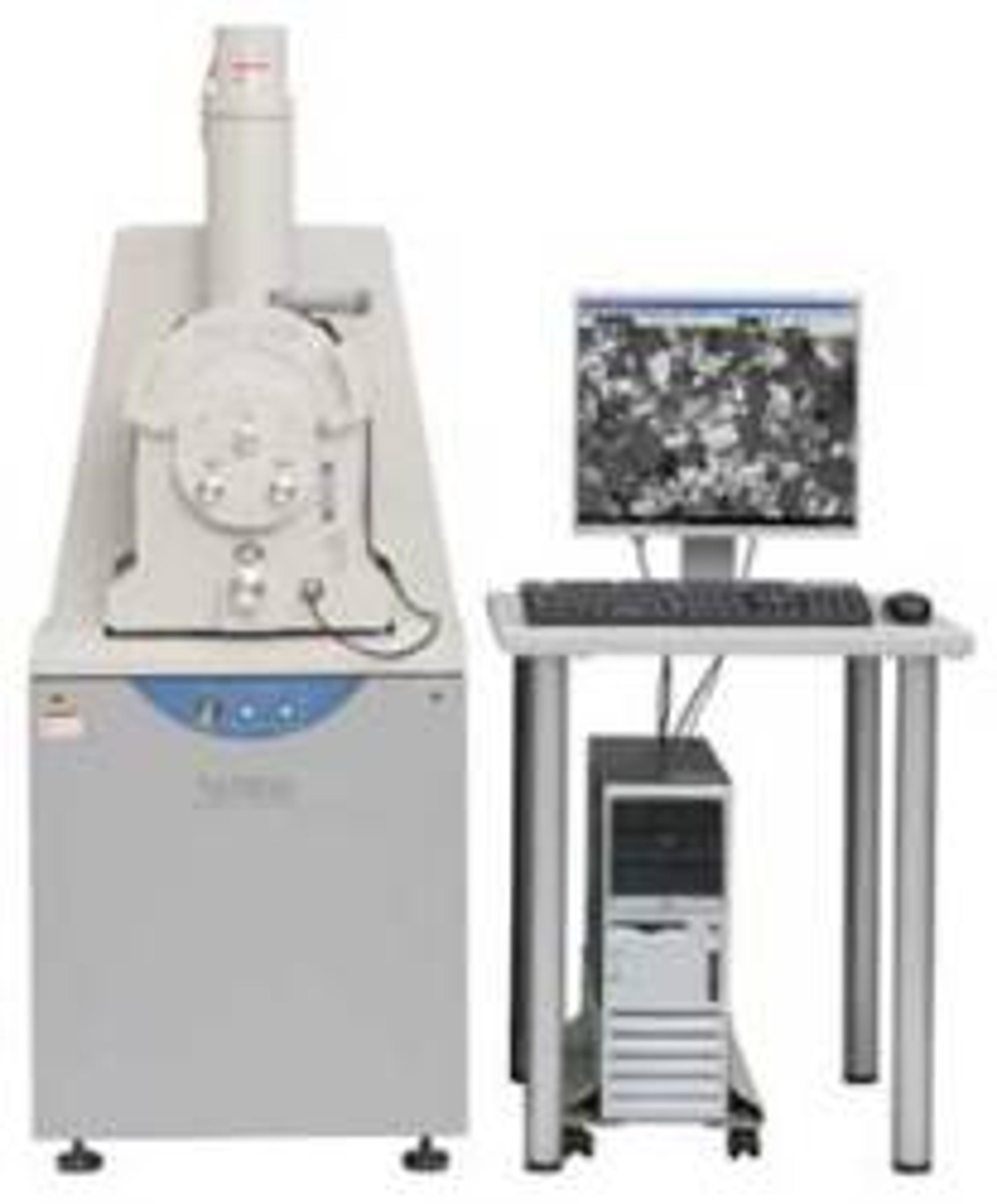

New Ion Milling system for SEM Sample Prep

1 Sept 2011Hitachi High-Technologies has launched the IM4000 Ion Milling system. Used to prepare specimens for scanning electron microscope (SEM) imaging and analytical studies such as EDX and EBSP, the versatile IM4000 is capable of both pin-point cross-section and flat surface ion milling. Cross-section milling provides smooth cross-section specimens for high resolution imaging of subsurface structures, with the cross section position accurately controllable by fine positioning of a beam-shielding mask edge. Flat milling provides uniform polishing of surfaces of 5 mm diameter or more with variable angle milling, to either flatten surfaces or to selectively enhance specimen surface features (relief milling).

The two IM4000 applications, cross section and flat surface milling, are realised via 2 different removable sample stage units, allowing for convenient specimen setting and cutting edge definition using an external optical microscope.

The IM4000 ion milling system features a new high-current Argon ion gun that delivers cross sectional milling rates of 300$)A&Lm/hr in Silicon for dramatically reduced cross-sectioning times. The wide Argon ion beam can define sharp cross sections even on samples of dissimilar materials with different hardness that cannot be cut or broken without causing material deformations or dislocations. Sensitive materials like polymers or papers can be processed by freely selecting proper lower ion beam energies between 0 and 6kV, without need for special sample cooling.

Wide and smooth flat milled surfaces of approximately 5mm in diameter or more can be achieved within minutes by shifting the centre of the defocused ion beam from the sample rotation or swinging centre. The beam irradiation angle to the specimen surface is selectable from 0$)A!c to 90!c. This makes the IM4000 useful in a multitude of different fields and applications such as materials, semiconductors, research and quality control.