New Software Allows Wyatt Technology’s Automated DLS Instrument to be used in Labs Operating Under GLP and GMP

6 Mar 2017

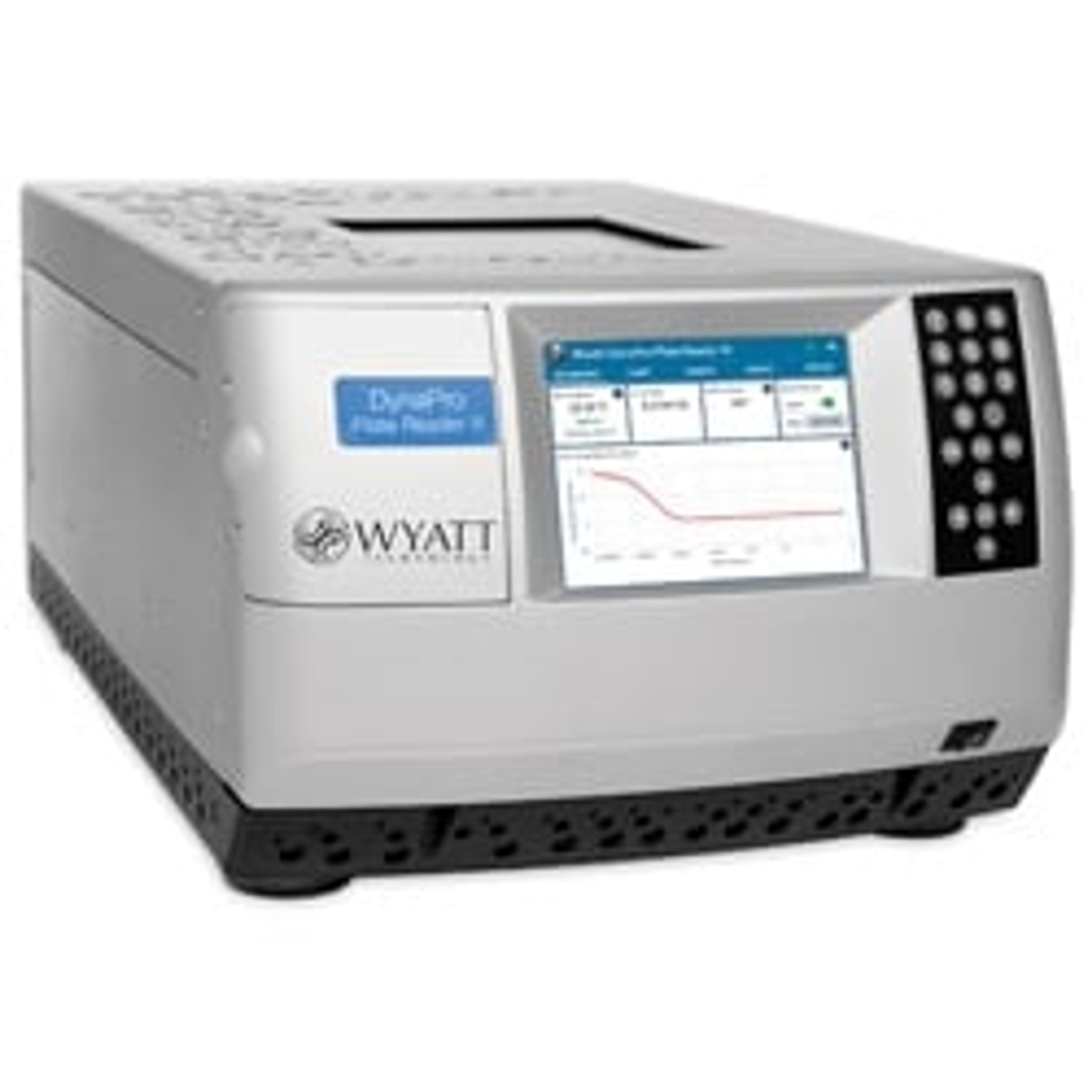

Wyatt Technology, a leader in instrumentation for absolute macromolecular and nanoparticle characterization, announces the release of its 21CFR11-compliant software for its groundbreaking DynaPro® Plate Reader II (PRII). The DynaPro PRII is the only high-throughput, automated dynamic light scattering instrument capable of measuring the size and stability of biopharmaceuticals and nanoparticles directly in microtiter plates, including the most popular 96, 384 and 1536 wellplate versions.

The DynaPro PRII is widely used in the biopharmaceutical industry to characterize aggregation as well as thermal, conformational and colloidal stability of biotherapeutics. It finds extended application in assessing the developability of candidate molecules with minimal sample consumption in order to identify promising therapeutics, and in the subsequent rapid development of stable, safe formulations.

The DYNAMICS® software for control, data acquisition and extended analysis of dynamic light scattering data, is included with each instrument. With the release of the 21CFR11-compliant Security Pack (SP) in DYNAMICS, labs operating under GLP or GMP regulatory requirements may now take advantage of the DynaPro PRII’s automation to measure dozens, hundreds or even thousands of samples per day.

Additional instruments for GLP and GMP labs

DYNAMICS SP supports additional advanced instrumentation from Wyatt Technology besides the DynaPro PRII. The DynaPro NanoStar, a traditional cuvette-based dynamic light scattering detector popular with protein scientists due to its high sensitivity and ultra-low sample requirement, has also seen early adoption into GxP labs, as has Wyatt’s Möbius zeta potential/dynamic light scattering instrument.

With the release of DYNAMICS SP, any GMP or GLP lab that requires determination of nanoparticle size, protein aggregation, or the zeta potential of a drug delivery or diagnostic nanoparticle is now empowered to reduce hands-on time and increase throughput, thanks to the automation made possible by operating the DynaPro PRII or the Möbius with DYNAMICS SP.