Optimum Pipette Tip Alignment with Hamilton’s PerfectTouch Tip Technology

27 May 2013

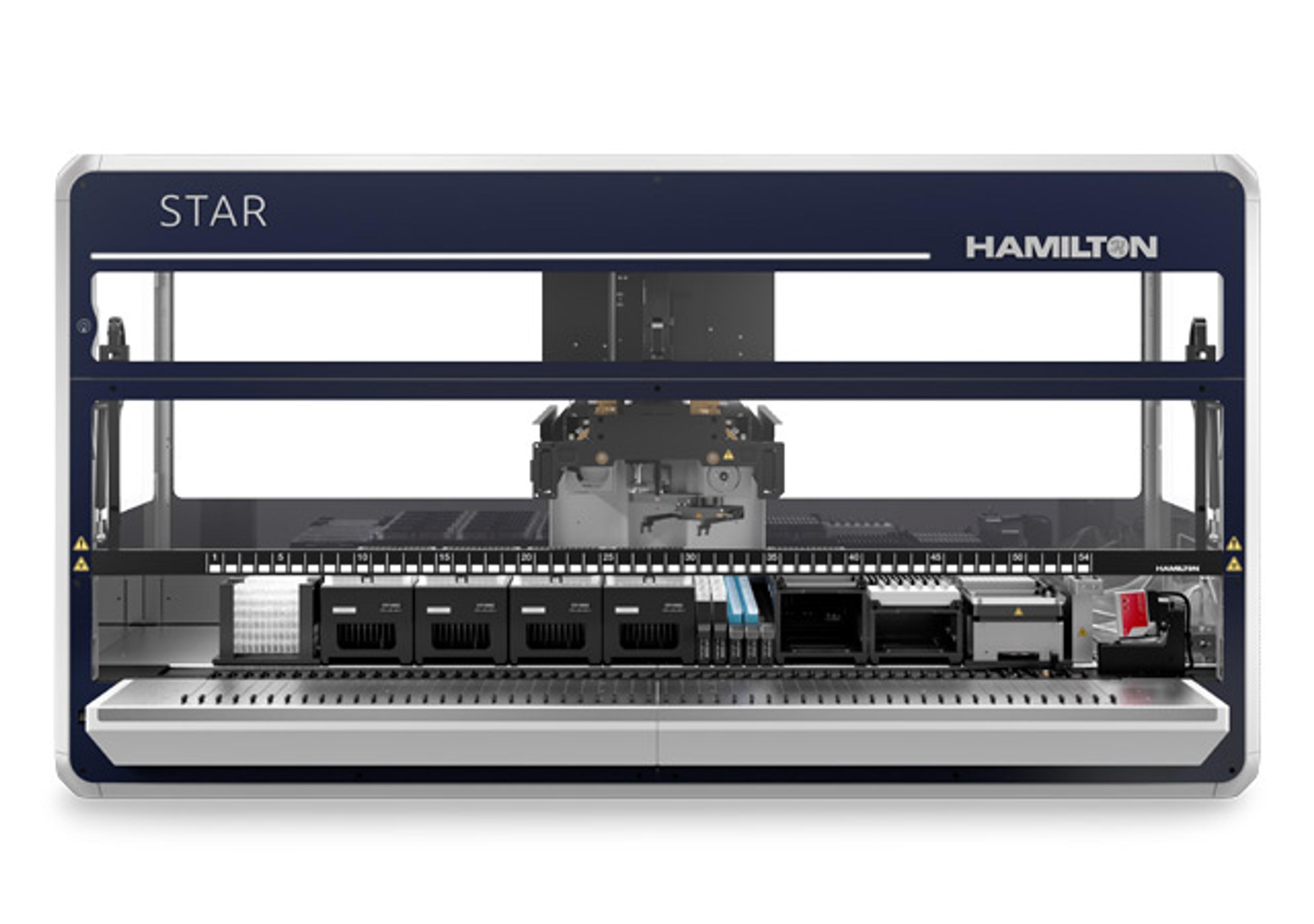

Hamilton developed the STAR and NIMBUS lines to meet the demands of the most flexible and reliable automated pipetting solutions in genomics, proteomics, cellomics, forensics, drug discovery, diagnostics and biobanking.

We designed a superior pipette channel which locks on (lock-and-key fit) to the special Hamilton disposable tips rather than the standard method of forcing a tip on a mandrel. Each Hamilton tip features inside the attachment orifice an annular groove, which ensures an air-tight seal between the tip and the pipetting channel.

This new design, patented as CO-RE (Compressed O-Ring Expansion), leads to unrivalled advantages in regard of optimum tip alignment, eliminating tip distortion, and minimizing the risk of aerosol contamination by aerosol-free tip drop-off. We call it simple the “PerfectTouch Tip Technology”.

Tip alignment is critical for positioning the orifice of the tip at the correct height of the liquid for accurate pipetting as well as locating the tip precisely within the horizontal plane of the labware. The annular groove design of the Hamilton tip allows the exact seating of the locking O-ring within the tip for proper vertical and horizontal alignment.

Hamilton tips are dropped off by relaxing the O-ring and allowing gravity to pull the tip down. This way tips are gently released in a controlled fashion with the least vigor and vibration thus minimizing the potential for liquid remaining on the tips to become airborne and contaminate the pipetting workspace.

With Hamilton CO-RE PerfectTouch Tip Technology consistent sample pickup of all channels provides excellent reproducibility and accuracy. Improved system reliability by minimized mechanical stress for tip attachment/tip ejection supports an optimized workflow.

With skilled personnel and fully automated ISO Class 8 clean room production we enable contamination-free manufacturing of our disposable tips. Our CO-RE tips get the superior “Biological purity tested” certificate.

Hamilton PerfectTouch tips are digitally inspected by vision systems during the production process to make sure that the orifices and concentricity do not vary. To further minimize variation, only tips from one cavity are packed in a SBS tray (24, 96 or 384 tips).