Organoids, Disease Models and 3D Printing: The Challenges and Opportunities for 3D Cell Culture

We explore the advantages of culturing cells in three dimensions over traditional methods and look at the exciting new developments for the technology behind 3D cell culture

27 Aug 2019

Historically, cells used in research have been grown in two dimensions, as it makes the cells easier to grow and is much more convenient. But consider mammalian cells used for research and where they come from in the body. They live, and grow, in a three-dimensional structure, with surrounding partners. When you go from two dimensional to 3D structures, you have a more in vivo-like environment for your cells and therefore generate more relevant data not only for research, but for the development of drugs to treat diseases such as cancer, where you can replicate the tumor structures, or even regenerative medicines. That's why more and more researchers are now growing cells in three dimensions.

Corning has been producing flasks and vessels to grow cells in three dimensions, along with the necessary reagents and media, for decades. Now, it focuses its efforts on designing systems that enable scientists to apply 3D cell culture methods easily and reproducibly. Here, we talk with Dr. Nicolas André, scientific applications and business development manager at Corning Life Science, to discover the applications of 3D cell culture for modeling disease, its benefits over traditional cell cultivation in two dimensions and the exciting new opportunities and challenges facing cell culture. We also hear from Dr. Tram Ngo, Senior Associate Scientist at the Sanford Burnham Prebys (SBP) Medical Discovery Institute to see how 3D cell culture opens up new avenues for cancer and Alzheimer’s research.

Organoids, disease modeling and personalized treatments

Scientists are looking to improve disease modeling and create more personalized treatments using organoids, small 3D structures derived from stem cells that mimic the complexity of an organ. Taking cells directly from a patient, and growing organoids based on these cells, an ‘organ in a dish’ can be created and used to test different drug compounds. “Science is based on models. You start with a simple model, and then see what you can do to increase the complexity,” says André. “Using organoids, you can test your compounds in vitro before going in vivo, and in a much more personalized way.”

While organoids have been developed that represent most organs, such as the heart, liver or kidneys for example, researchers are looking to expand into new models. Pulmonary organoids that can replicate the interface between the air and liquid may be next on the list and would be valuable for research and drug testing.

Pre-clinical research

Being able to identify toxic compounds as soon as possible within a drug discovery workflow is highly beneficial, reducing development costs and improving safety. A newer function of 3D cell culture is its application to in vitro toxicity assays on organoid structures. André tells us that, “the use of three-dimensional cell culture and organoids have helped people to test for toxicity in a safe way and to identify compounds that are toxic in advance, to either dismiss them or modify them to reduce or decrease toxicity.”

3D printing of cells

Recent developments in cell culture technology have looked to combine the latest fabrication and 3D printing technology with cellular biology to create 3D printed organoids that bring us closer to in vivo conditions. “You can create a model system in a dish that is very similar to what you can see in a body of a patient. Therefore, you can test drugs and try to understand the actions of compounds or pathways,” says André.

We try to bring high-quality standard products that help people to jump easily into the 3D world, and be able to reproduce data to go further.

Dr. Nicolas André Corning Life Science

Method harmonization

When talking about 3D cell culture and organoids, there's a large variety of methods that are used. Sometimes the conditions that are described are difficult to reproduce and that makes it difficult to go further and faster. It's the question of having very robust methods, robust tools and clear ways of analyzing the results. One of the challenges is to be able to get some more harmonization in the way people do their work.

Scalability

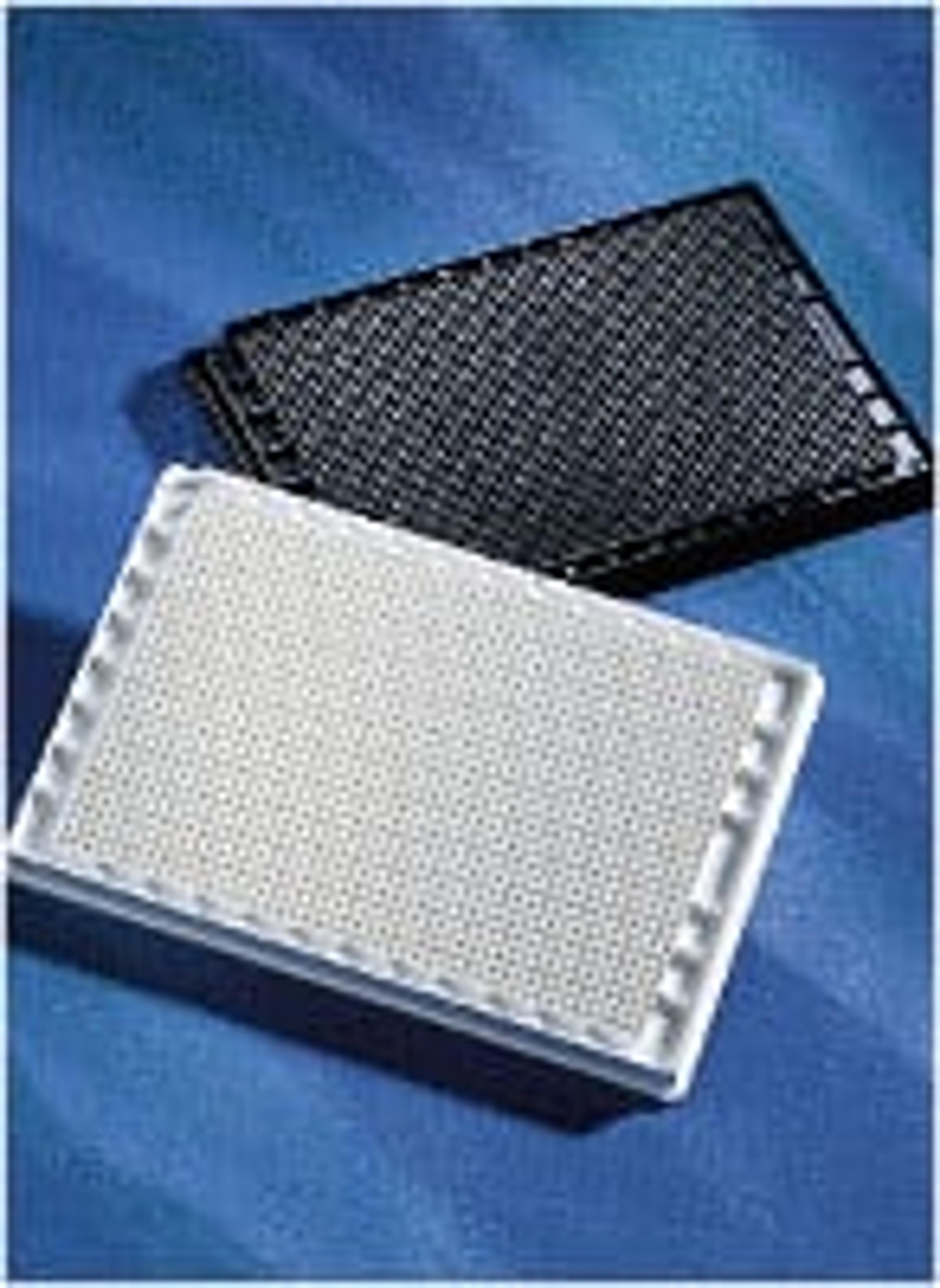

To go from a small-scale experiment where you have one person doing a single experiment in a dish, to someone who can do thousands, or even hundreds of thousands of tests very rapidly isn’t easy but is one of Corning’s goals. “We have the spheroid plate, which is a plate which goes from 96-, 384- and 1,536-well formats, where you can grow individual 3D cell structure in a well,” explains André. “Using automation, you can test compounds on those. You can do a hundred or millions of compounds in just a few days."

What does the future look like for 3D cell culture?

André tells us that one of the next steps could be to apply this approach to regenerative medicine: "Would scientists be able to recreate organs, to transplant them based on your own cells and grow them in a dish, to be able to develop cures or replace organs? That's far away from where we are today, but this is one of the goals.” 3D cell culture will be at the heart of this mission, for both pre-clinical development and toxicity testing, but also afterwards, for originality of medicines.

We asked Dr. Tram Ngo, Senior Associate Scientist at the SBP Medical Discovery Institute, about her work and the importance of efficient cell culture:

Please introduce yourself and tell us about your role at the SBP Medical Discovery Institute

My name is Tram A. Ngo, I have a MS in Health Sciences from George Washington University and around 24 years’ experience of working in the biotechnology and pharmaceutical industries. I’ve been working at SBP Medical Discovery Institute as a Senior Associate Scientist since 2009 and primarily focus on assay development and high-throughput screening for projects that aim to find lead compounds for cancer and Alzheimer’s research.

Tell us about the importance of efficient cell culture to your research

Most of the assays that we develop for cancer research are cell-based assays, therefore it is important to choose the best cell line for our research. To keep these cells healthy, the right culture techniques are also very important. We also do a lot of high-throughput screening and high-content screening, so the conditions of the assay must be optimized at a higher level for the screen.

Where do you see the challenges and opportunities for your research in the future?

The challenges for high-throughput screening and high-content screening when you work with cells are:

- Avoid contamination

- Must get good attachment of cells to each well of the microplate

- Avoid edge effect, where medium evaporates from the perimeter of the plate during incubation and skews your results

- The most important factor is often to reduce the costs involved

In terms of opportunities, we have been working closely with vendors to improve our research goals by improving the equipment and products that we use. We’re doing this by getting better, more suitable plates (coated vs non-coated plates), better plate washers and readers, and more sensitive reagents. All these factors are collectively improving the way we do our research.

For what applications do you use the Corning 1536 Well White Polystyrene TC-Treated Microplate?

We use a lot of Corning tissue culture products, including a lot of Corning 1536 Well White Polystyrene TC-Treated Microplates for high-throughput screening, and biochemical and cell-based assays.

Do you have any top tips or expert insight to get the best cell culture results?

- To detach adherent cells, I prefer to use TrypLE Expess instead of Trypsin

- Check for Mycoplasma contamination every two weeks

- For both high-throughput screening and high-content screening, always filter the media and avoid cell clumps by putting cells through a cell strainer before dispensing them.