Select the Right Water Purification System for Your Lab

Written by Dr. Stephane Mabic, Worldwide Application and Training Manager, Millipore S.A.S.

24 Nov 2015

Select the right water purification system for your lab

Choosing a water purification system for a laboratory can sometimes seem like a complicated process. However, by taking the time to thoroughly evaluate your situation at the beginning of your search and considering a few key parameters, you can make the selection a little easier and have greater confidence in your final choice.

Figure 1. Parameters considered in the selection of a solution for purified water in the laboratory

1. List your water quality needs

First of all, it's important to know that several types of laboratory water exist. These water grades are defined by standards, which help ensure not only that the correct water type is used for a specific application, but also that cost considerations are taken into account, as Type 1 ultrapure water is more expensive to produce than Type 2 or Type 3 pure water.

With this in mind, identify the different situations in which purified water is used in your laboratory and for which applications. Type 1 water is required for critical laboratory applications, including mobile phase preparation for HPLC or IC; preparation of blanks; standard and sample dilution in HPLC, IC, GC, AA, ICP-MS, etc.; buffer and cell culture preparation for mammalian cell culture; reagent production in molecular biology applications; and preparation of solutions (electrophoresis and blotting).

Type 2 water is used in more general applications such as buffer and microbiological culture media preparation, as feed to other laboratory systems (Type 1 water systems, clinical analyzers, dish washers, cell culture incubators and climatic test equipment.) Finally, Type 3 water is the lowest laboratory water grade and is used in glassware rinsing, heating baths and autoclaves, or also as feed to Type 1 lab water systems.

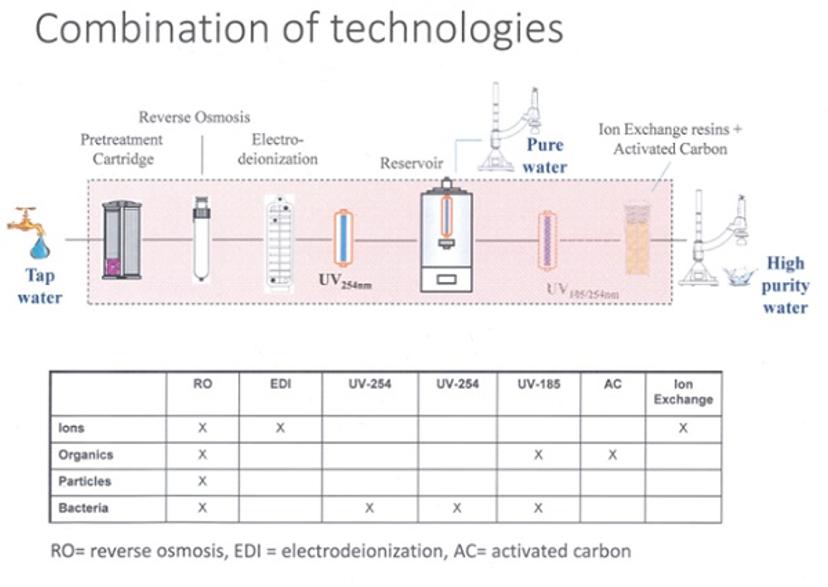

Depending on your situation, you will need to select a system that can remove water contaminants and produce pure or ultrapure water, or both. As no one technology can remove all contaminants, several purification technologies are generally combined to produce pure and ultrapure water. During your evaluation process, pay careful attention to the technologies used by the systems to make sure you will be able to consistently achieve the water quality needed over time, while also minimizing operating costs.

Figure 2. Different technologies commonly used in advanced water purification systems and the contaminants they remove

2. Evaluate your total water volume requirements

Based on the list of your purified water points of use and applications, now calculate approximately how much water you require per day for each water type. This will provide you with the basic information you will need to discuss recommended installation possibilities with your water purification system vendor. In your estimate, don't forget to take into account days when greater volumes of water may be required.

3. Understand the importance of monitoring and traceability

It is essential to know that your lab water purification system is continuously able to meet the specifications for your water quality needs. Monitoring tools, such as resistivity monitors, which measure the ionic purity of water (a 18.2 MΩ·cm reading means that the product water is ion-free) and total oxidizable carbon (TOC) meters, which indicate the total amount of organic material present in water, are commonly used for this purpose. Depending on the application, both resistivity and TOC values may be required, so these criteria should be considered in your choice of water purification system.

Being able to trace and record water quality is also important, especially for labs working in regulated environments. Millitrack® e-Solutions now provide the means to do this for many EMD Millipore systems, with enhanced data management control, remote access capabilities to the system dashboard, and long-term electronic archiving.

4. Consider certification and compliance

As part of the system selection process, you may also wish to investigate aspects concerning quality assurance. Look for systems that are produced in an ISO® 9001- and ISO® 14001- registered manufacturing site and which are delivered with the necessary quality documents, such as certificates attesting to conformity, quality, or calibration, for example.

In addition, keep in mind that water purification systems must comply with regulations that govern efficiency and safety throughout the lifetime of the equipment: look for equipment with CE, UL, and FCC-certification.

The laboratory water produced by water purification systems is also subject to standards that define the quality required for specific applications, such as those published by ASTM® and ISO® 3696 for laboratory applications, the Clinical and Laboratory Standards Institute® (CLSI®) guidelines for clinical labs, or those provided by pharmacopoeial bodies. If the water used in your labs must comply with standards from these organizations, be sure to check this point, too.

5. Strive for sustainability

It is true that the operation of any laboratory water purification system has a certain impact on the environment. However, manufacturers have made great progress in the development of sustainable solutions, and water systems on the market today reflect these changes in their reduced use of potable water, electricity, and strong chemicals, and in the availability of purification cartridges with longer lifetimes. In addition, excessive packaging has often been reduced and documentation is usually provided as electronic files, rather than printed documents. In the case of EMD Millipore, a recycling program has been introduced in the U.S. to help customers dispose of their exhausted purification cartridges economically and efficiently, allowing a reduction in environmental impact by approximately 10-12%, compared to landfill, and a reduction in cartridge waste by about 25-40%.

In addition to the points above, check that your vendor's systems follow European Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives.

Keeping your system in good condition with periodic preventive maintenance is also another way to reinforce sustainability and to ensure optimum operation throughout the equipment's lifetime. Check with your vendor to make sure that they have a professional service organization to meet your needs.

6. Don't forget design

By now you have determined where and when you need pure and ultrapure water, for which application(s), and in what volume and frequency. The actual design of the lab incorporates this information with other important criteria that should be discussed with your lab water purification vendor.

A larger lab may opt for a solution that involves distributing pure water through a loop, or implementing a floor-by-floor set up in response to volume or water purity needs, while smaller labs may prefer to use individual systems providing pure and ultrapure water on demand. In environments subject to regulatory requirements where full system control and complete traceability is needed, lab configuration may be determined by the need to install a number of point-of-use systems using Millitrack® Compliance software.

Finally, don't forget that other stakeholders, such as members of building/ facilities management or the purchasing department may need to be involved in the decision. Several criteria should be considered to guide the discussion with the water purification system vendor and select the solution.

Thank you to Dr Mabic for this interesting article - to learn more about water purification, download our editorial buying guide or read 10 Ways to Improve Your Lab's Water Quality.