T Cell Engineering for Breakthrough Immunotherapy Research

Discover the world’s only fully automated, GMP-compliant, CAR T cell manufacturing system

3 Jul 2017

Immunotherapy is one of the most exciting areas of cancer research today. Metastatic cancer, in particular, remains particularly challenging, as a systemic treatment approach is required. T cells play a vital role in the immune response against cancer and scientists are now looking at ways to harness the body’s own immune response against tumor cells.

The adoptive transfer of T cells expressing genetically engineered chimeric antigen receptors (CARs) has shown great potential in the treatment of certain leukemias. In CAR T therapy, T cells are removed from the patient and modified to express tumor-specific CARs on their surface. The T cells are then reintroduced to the patient, where they can recognize and kill the targeted cancer cells.

Dr. Katharina Winnemöller, Marketing Manager, Miltenyi Biotec explains: “Engineering T cells is a booming area for cell therapy manufacturers, hospitals and centers of excellence around the world. The data has shown this to be a breakthrough treatment for cancer, and so a lot of money is being invested in the technology.”

Manufacturing challenges

The preparation of CAR T cells for clinical application is a complex process, not least because national and international legislation and regulations must be rigorously followed. Manual production of engineered T cells is extremely labor intensive, each processing step must be stringently controlled. Miltenyi Biotec has developed the world’s only available all-in-one solution for cell processing, in a closed GMP-compliant, fully automated system. The CliniMACS Prodigy® enables the entire workflow for the manufacture of CAR T cells, from T cell selection right through to cell formulation.

Each processing step is automated to ensure a highly reproducible and standardized manufacturing process. T cells are enriched by specific selection on Day 0 during the T cell transduction process (TCT process). On Day 1, T cells are transduced with a lentiviral vector. The transduced T cells are then expanded to the desired cell number for final cell formulation. The fully automated nature of the system means that the end product is completely standardized. This high level of quality is crucial for manufacturers, but it also saves money and materials, and eliminates the possibility of user error.

The CliniMACS Prodigy®

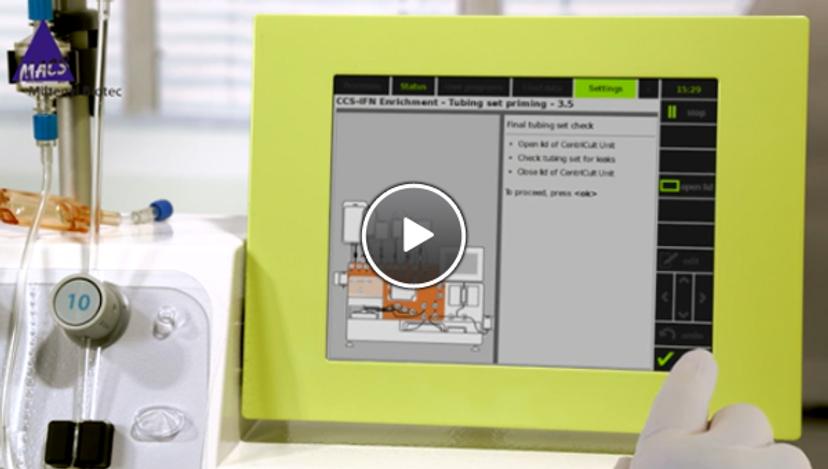

The CliniMACS Prodigy® enables the magnetic separation of different cell types as well as customized cell processing protocols. This flexible platform automates the washing, fractionation and cultivation of cells. A layer detection camera automatically determines the optimal cell fractionation endpoint by discerning the macroscopic layers of the source cell product.

The Miltenyi Biotec team is on hand to help their customers throughout the entire implementation process, starting with a thorough three-day training course on running the instrument. Customers can change the settings to adapt the process to suit their needs. There is also a large team of technical support available to support all users. “The support service that we offer to all of our Prodigy customers is a crucial part of the package that you purchase with your system. We provide training and technical support to our users, and we have developed fantastic relationships with our customers as a result,” says Dr. Winnemöller.