The Handheld Raman Technology Ensuring Biopharmaceutical Quality, from Start to Finish

Discover the handheld Raman spectroscopy analyzer advancing biopharmaceutical material identification

28 Aug 2018With an increasing demand for biopharmaceutical drugs, an efficient workflow that meets the required GMP and Pharmacopeia guidelines is essential for manufacturers. Quality control and quality assurance measures are important when meeting these guidelines and ensuring consistency of the biological products produced.

There are several important QC/QA steps in the biopharmaceutical manufacturing workflow including raw material inspections, water quality, sterility tests, and purity tests; the ability to analyze the molecular properties of these different samples accurately and rapidly is a key focus for the industry.

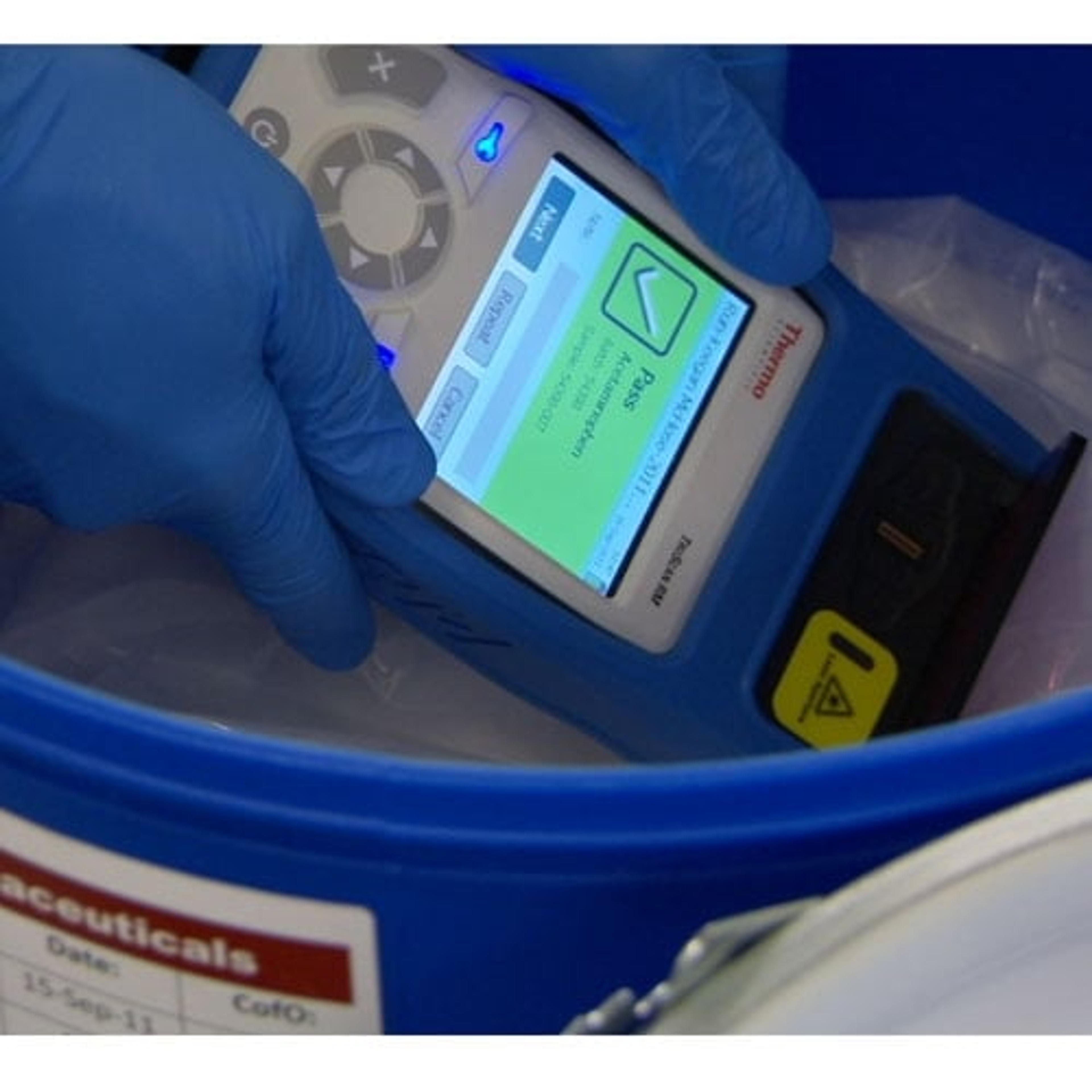

Biopharmaceutical manufacturers increasingly use handheld Raman spectroscopy technology for raw material, in-process materials, and fill-finish product QC/QA. With the ability to test materials at the point of need, they reduce the necessity for laboratory sample testing and enable manufacturers to make informed decisions faster, at-line.

In this SelectScience interview, we speak to Shailesh Karavadra from Thermo Fisher Scientific to learn about the Thermo Scientific™ TruScan™ RM analyzer with TruTools™ embedded chemometrics and how this technology is helping scientists in the biopharmaceutical industry to rapidly perform customized qualitative and quantitative analysis of complex materials.

SS: Briefly introduce yourself and tell us about your role at Thermo Fisher Scientific.

SK: My name is Shailesh Karavadra, I am a technical sales manager covering the UK, Ireland, and Scandinavia, and I have over 15 years of experience in the molecular spectroscopy industry. My work involves educating customers about implementing Thermo Scientific handheld spectroscopy devices in their manufacturing plants to improve quality, process workflows, and achieve compliance.

SS: Why is QC important in the biopharmaceutical manufacturing process and what are some of the critical steps and considerations?

SK: The active substances in biological products are often too complex to be fully characterized by utilizing physicochemical testing methods alone and may show a marked heterogeneity from one preparation and/or batch to the next. Consequently, special considerations are needed when manufacturing biological products to maintain consistency in product quality. Quality control is one of the most important attributes of GMP guidelines. All manufacturers must adhere to cGMP guidelines and additional requirements of various Pharmacopeias for quality control.

Demand for biopharmaceutical drugs is ever-increasing and manufacturers are making large efforts to keep up with meeting the needs for this space. To meet the production requests, manufacturers have to introduce rapid inspection/QC methods at various stages of upstream and downstream processing. Some of the critical steps in QC of biopharmaceutical products are raw material inspections, water quality, sterility tests, and purity tests.

SS: How do the TruScan RM handheld analyzer and TruTools help biopharmaceutical manufacturers to meet QC requirements?

SK: TruScan RM can now be equipped with TruTools chemometrics software, enabling biopharma manufacturers to complete identification tests of their various raw/starting materials like cell culture media, buffers, inorganic polyatomic salts, amino acids, polysorbates, and many others. Cell culture media may have batch-to-batch variance and a Principle Component Analysis (PCA) model deployed on the TruScan RM can identify such variance and reduce inconsistency in the final product formation. As the nature of cell culture media is a critical quality attribute (CQA) and has a strong impact on the outcome of finished products, robust material variance and stability testing is important.

In material stability testing the cell culture media is studied for any changes to properties during expected shelf life, within recommended temperature and storage conditions. TruScan RM with TruTools has had success in determining stability as well as identifying batch-to-batch variations in raw materials for cell cultures.

TruScan RM with TruTools can also be used as an offline analyzer to quantify critical components like glucose, lactate, glutamate, and glutamine in fermentation broth from a liquid reactor. Such quantification tests take less than a minute and give process engineers and operators good insight into final yields and faster reaction time with which to monitor the process.

In addition, TruScan RM with TruTools can help manufacturers to complete final product identification testing through their packaging, which again saves significant time and costs involved with traditional testing methods.

SS: Describe your work on custom qualitative and quantitative models you have built for TruTools and how this will help the industry.

SK:We have done various feasibility studies on final product identification and have worked with diverse manufacturers to demonstrate TruScan RM with TruTools’ capabilities. Our experience so far has proved to be successful. Pharmaceutical manufacturers can deploy TruScan RM to qualify or quantify their final products. We have developed methods based on PLS-DA (partial least squares-discriminant analysis) to monitor critical parameters of raw materials and raw material identification methods based on PCA to monitor batch-to-batch variations. In a recent real-world example, a pharmaceutical manufacturer sought to differentiate between several different biologic drug products and to distinguish between a protein product and its placebo. Using TruScan RM with TruTools the manufacturer was able to confirm the presence of a protein, that is, distinguish between a therapeutic protein product and its placebo. The testing also successfully differentiated all six different biologic drug products from each other.

TruScan RM has the potential to be faster, less labor-intensive, and less expensive (lower unit test cost) than conventional testing methods. It can also offer good reproducibility and comparability to chromatographic methods.

SS: What do you see for the future of biopharma and what part could TruScan RM technology play within that?

SK: As biopharma manufacturers are increasing the testing regimes and increasing their efforts to raise current production levels, TruScan RM with TruTools will play a vital role in quality control of incoming raw materials, in-process monitoring, and final product testing.