The trick(s) to brewing quality beer: A microbiology perspective

Explore the importance of quality control in beverage analysis and discover top tips to optimize your beer production workflow

20 Dec 2021

The food and beverage industry is highly regulated, and rigorous quality control (QC) testing provides confirmation that good production standards are being met and confidence that the end-product adheres to regulatory criteria. Skipping essential QC testing can result in off-flavoring and reduced potency of the product, as well as negative brand impact for the manufacturer. In this SelectScience® article, beer quality experts Tricia Vail and Wayne Garafola explain why QC has the potential to make or break a beverage.

Global considerations for beverage QC

According to Tricia Vail, Regional Business Manager for Microbiology & Lab Filtration at Sartorius, releasing a beverage product without quality control is difficult in many countries worldwide. “The quality considerations that go into testing differ not only by different beverage types, but also by local restrictions,” shares Vail. “It is important to know how the beverage will be classified from a regulatory standpoint, and then adapt the QC testing procedures to meet these set regulatory requirements.”

For example, for sparkling water, the regulations and testing requirements differ regionally. In Europe, the Middle East and Africa, sparkling water is regulated the same as still water. However, the US FDA regulates sparkling water as a soft drink, with standards different from those set for still water, as regulated by the US Environmental Protection Agency. Countries also differ in their ‘alcohol by volume’ requirements for alcoholic drinks such as beers, wines, and spirits. Not only must the drink labels carry this information, but the manufacturers must also adhere to the standard stipulated in each country where their product is marketed.

The importance of QC for top-quality beer

When it comes to brewing first-class beer, having a robust QC program helps brewers swiftly address any challenges faced during the brewing and manufacturing process. Such programs can help highlight issues with the production equipment, fluctuations with the water used for brewing, or even contamination from wild strain yeasts or spoilage microorganisms. Incorporating test methods to adjust the brew recipe before production begins can also be extremely useful in beer QC. “The presence of spoilage microorganisms can make the beverage skunky, off-flavor, and potentially hazardous to drink,” explains Vail. “This makes microbial QC testing a crucial aspect of beverage analysis. It is also an easy test to perform as it just requires filtration through a 0.45um membrane, followed by checking for growth by placing the membrane on a microbiology media surface.”

However, having a QC program in place is only half the battle won; you must also ensure it is adhered to. Vail highlights that a few crucial tests, such as testing for moisture in the raw materials or testing the water quality used for production, are still regularly overlooked. For example, dry goods (e.g., malt, hops or barley) are purchased and often stored within the brewery. Over time these goods pick up moisture in the air and this increase in moisture level can interfere with the yeast budding process, resulting in off-flavoring or even inaccurate alcohol by volume measurements, which incurs regulatory repercussions.

Optimizing the beer QC workflow

There are also manymeasures that microbiology and analytical labs can adopt to optimize the QC workflow for beer production. “Regardless of when the beer is being tested, always cool it down to 2 to 8°C before filtration, and unless the test is for determination of carbonation, agitate the beer to remove as much of the carbonation as possible,” Vail shares. “We have found that doing both of these steps makes the beer easier to filter and prevents the carbonation from interfering with testing, ensuring consistent results.”

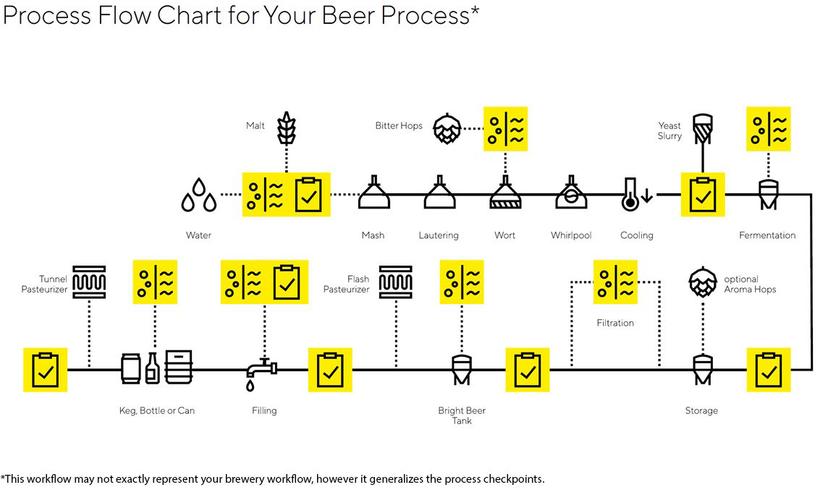

Having the best testing setup and products to aid the beer production process can help ensure optimized QC during brewing. Leading laboratory production equipment suppliers, like Sartorius, offer a wide range of products to help breweries adhere to the required quality standards throughout the production process. For example, “The Sartorius Jumbo Star Sartopure®clarification filter works to reduce the time between the fermentation tank and bright beer tank steps in brewing,” elaborates Wayne Garafola, Food & Beverage Account Manager at Sartorius. “As compared to the plate and frame design in standard filtration systems, the Jumbo Star setup can reduce time by 50% between steps, while also minimizing beer loss. The filter can also be easily regenerated using water and cleaning agents commonly found on the brewing operations floor.”

Garafola elaborates, sharing some of the other tools that the beer quality experts consider to be must-haves when brewing, including weighing balances to check weights on the production line, moisture analyzers that allow quick and multi-sample analysis, microbiology testing filters such as membrane filters for spoilage microorganisms, as well as yeast titers and filters that test for sterile water.

A collaborative future for flavorful brews

The brewing industry has transformed in recent years due to increased communication between research and manufacturing. Not only has the production process benefited from various enhancements due to this collaboration, but new beer flavors have also been introduced, with some movement towards non-alcoholic beer. “A stronger relationship between research and industry has solidified our ability to understand how yeast ferments,” says Garafola. “This has provided more insights on the different variations of yeast, therefore increasing the number of brewing methods to choose from.”

Looking to the future, Vail predicts an increased research focus on understanding and testing raw materials such as water, hops, malt, or barley. The impact of microbiology on the production process is also attracting a lot of research attention. “Making sour beers is becoming very popular and it requires the addition of microorganisms such as Lactobacillus, Pediococcus and even Brettanomyces,” Vail shares. “However, breweries do not have the ability to have a dedicated ‘sour’ production line, posing the risk of cross contamination when moving from sour beer production to any other beer type. Understanding the scientific principles involved in sour beer production is likely to provide a potential solution to this issue.”

Waste reduction and process improvement is also a focus in the brewing industry, evidenced in the efforts dedicated to maximizing the performance of filtration steps and reducing the replacement frequency of filter pads. “The innovation we are seeing has and will continue to enable brew masters to excel in creating unique beers with more flavor and nutrition than ever before,” concludes Garafola.

Click here to read more tips and tricks that can optimize your lab production workflow and ensure beer quality control.

Want to learn more about solutions Sartorius can support for the beer industry? Explore here >