Top tips for increasing reproducibility in the lab

From biopharmaceutical advancements to Egyptian dye identification, learn how scientists are using Gilson IoT solutions to enhance their research

19 Mar 2020

Labs are becoming more and more connected, bringing scientists increased comfort in the knowledge that their work is both traceable and highly repeatable. Here, Tiphaine de Jouvencal, Product Manager at Gilson, tells SelectScience about the various benefits of the Gilson IoT range of products. Additionally, we also hear from Yun Zhao, Director of the Biopharma Services Department at Admera Health, whose group is making the most of this cutting-edge technology in its biopharmaceutical research.

In early 2018, Gilson launched the first of its Internet of Things (IoT) products — Gilson Connect, a cloud-connected platform that powers a line of Bluetooth®-enabled, smart liquid handling devices including the TRACKMAN® Connected and PIPETMAN® M Connected, each designed to help scientists achieve verifiable science.

Learn more about how to connect your lab >>

SS: How does this product line help customers?

TJ: We created the PIPETMAN M to follow what happens at the bench. Currently, when performing manual liquid handling, you have no traceability because it's just the researcher, the pipette, and their draft, or a similar combination to that.

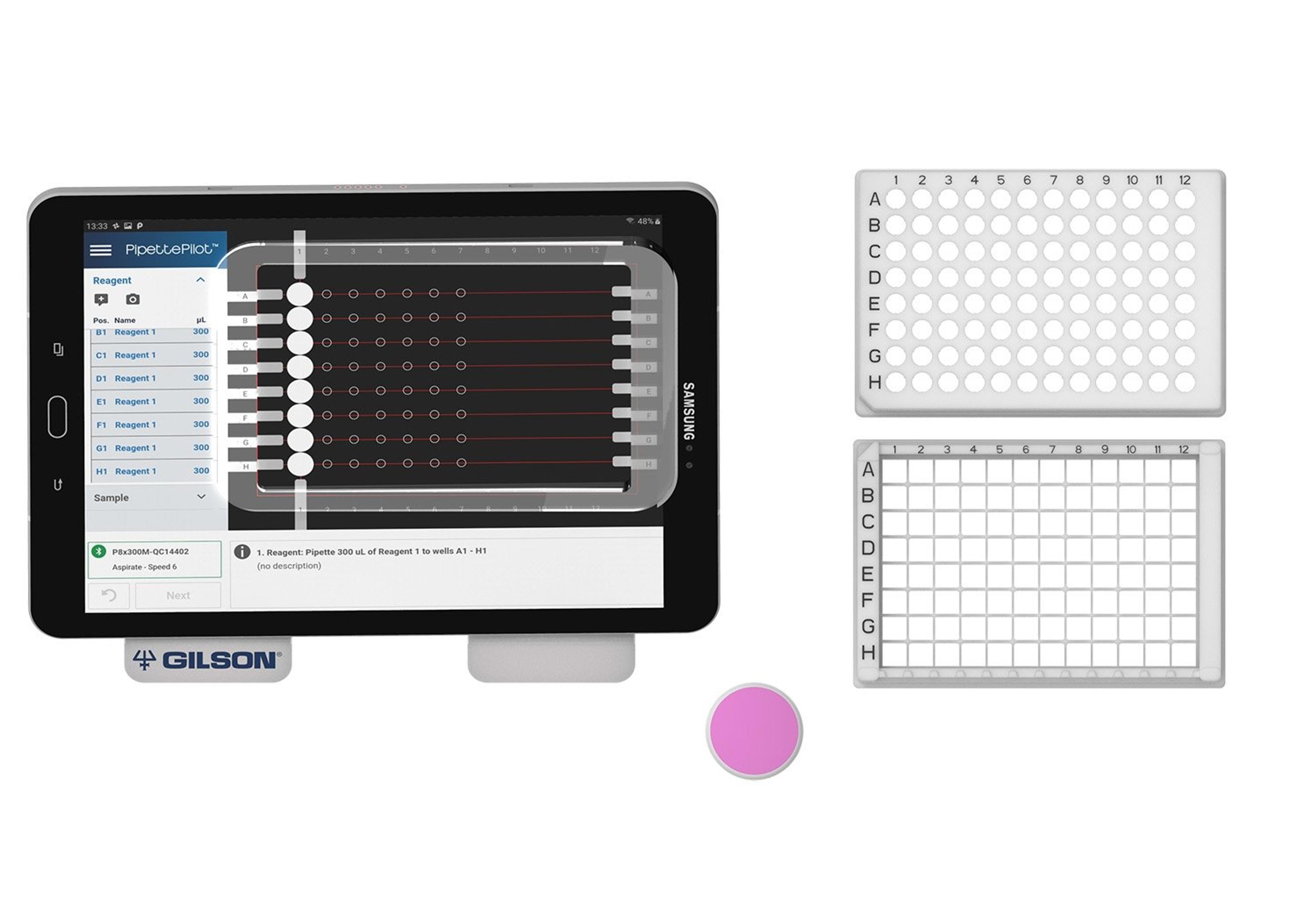

Because of these reasons, we created the PipettePilot® app, which helps follow and execute workflows, so our customers can create an experiment or load an existing one. Once their pipette is connected to the app, it allows researchers to perform the experiment and all of the data is automatically tracked on the application. The app also has many reporting features. We can save customers time because, at the end of an experiment where they are using PipettePilot, we automatically generate reports based on their actions. This means the researcher does not have to rewrite their notes during or after a protocol, reducing the risk of errors and saving time.

The point of using our system is not to say, "Hey. We're able to connect our pipette by Bluetooth," but more importantly to bring traceability to the bench.

SS: What sort of labs do you see using this product?

TJ: We are finding that the most prominent area is biotech, and more specifically, start-ups that arise from academia. They want to have traceability and follow the rules of their preferred industry in order to be more attractive for the customer when providing certain services. The fact that we record and report on pipetting actions is really important because it adds better traceability and reproducibility to their research.

SS: How easy is it to use Gilson IoT solutions?

TJ: We’ve made the application intuitive so that the researcher can use it without having to understand everything or add additional steps in comparison to manual liquid handling.

We mustn’t add extra steps, causing the customer to lose time while performing their experiments. What we have done is manage all of the day-to-day, repetitive steps for them.

For example, when you connect the pipette to the tablet and application, PipettePilot automatically sends the volume to the pipette, and then the pipette sends back the information communicating that the pipetting has been done. The researcher does not have to worry about which volume to set the pipette to because this is something the system can manage itself. So, if there were multiple different volumes to aliquot, the system changes it automatically, and we let them concentrate on other aspects of the experiment.

See TRACKMAN Connected video tutorials >>

SS: Have you found that this has increased the reliability of their results?

TJ: Yes. First, the systems help our customers become more efficient and save them time while also bringing greater traceability and reproducibility to the bench. Additionally, our other app, PipetteScope®, allows users to check their pipette to make sure everything is up-to-date and calibrated correctly. Both of our apps, PipettePilot and PipetteScope, communicate with each other through this information to ensure our customer’s pipette is in working order before beginning an experiment. We want to be sure they always have everything they need right at their fingertips.

CASE STUDY: Insights from the lab, with Yun Zhao, Director of the Biopharma Services Department at Admera Health.

Zhao is a researcher using TRACKMAN Connected and PIPETMAN M Connected. The Biopharma Services Department at Admera Health produces in vitro diagnostics in the form of pharmacogenomic testing, next-generation sequencing of solid tumors, liquid biopsy for cancer, and genetic tests for cardiovascular disease prediction and differential diagnosis. It also has a research sector, which partners with biopharmaceutical companies, biotech companies, and academic researchers to provide sequencing and bioinformatic services.

Zhao uses the TRACKMAN® Connected system to automate the group’s protocols and processes. Zhao states: “The system takes the guessing out of our pipetting protocol. We can track all of our pipetting activities and then look back at the data to see where we made a mistake, helping us to catch our errors before they cause problems down the road.” This system, plus the step-by-step reporting features within the PipettePilot app, allows Zhao to manage his pipetting activity in an easy and trackable way.

Zhao adds that the reduced impact of pipetting errors has led to a noticeable improvement in his group’s efficiency: “Before we adopted TRACKMAN Connected, our group all did an outstanding job. However, compared to our previous work, I have noticed that we need fewer people to run a protocol, allowing our team to be more efficient.”