Webinar Highlights: Get Automated - Achieve Your Automation Potential for Released N-Glycans

Discover a new rapid, efficient and reproducible solution for a traditionally complicated method: released N-glycan profiling.

19 Dec 2017

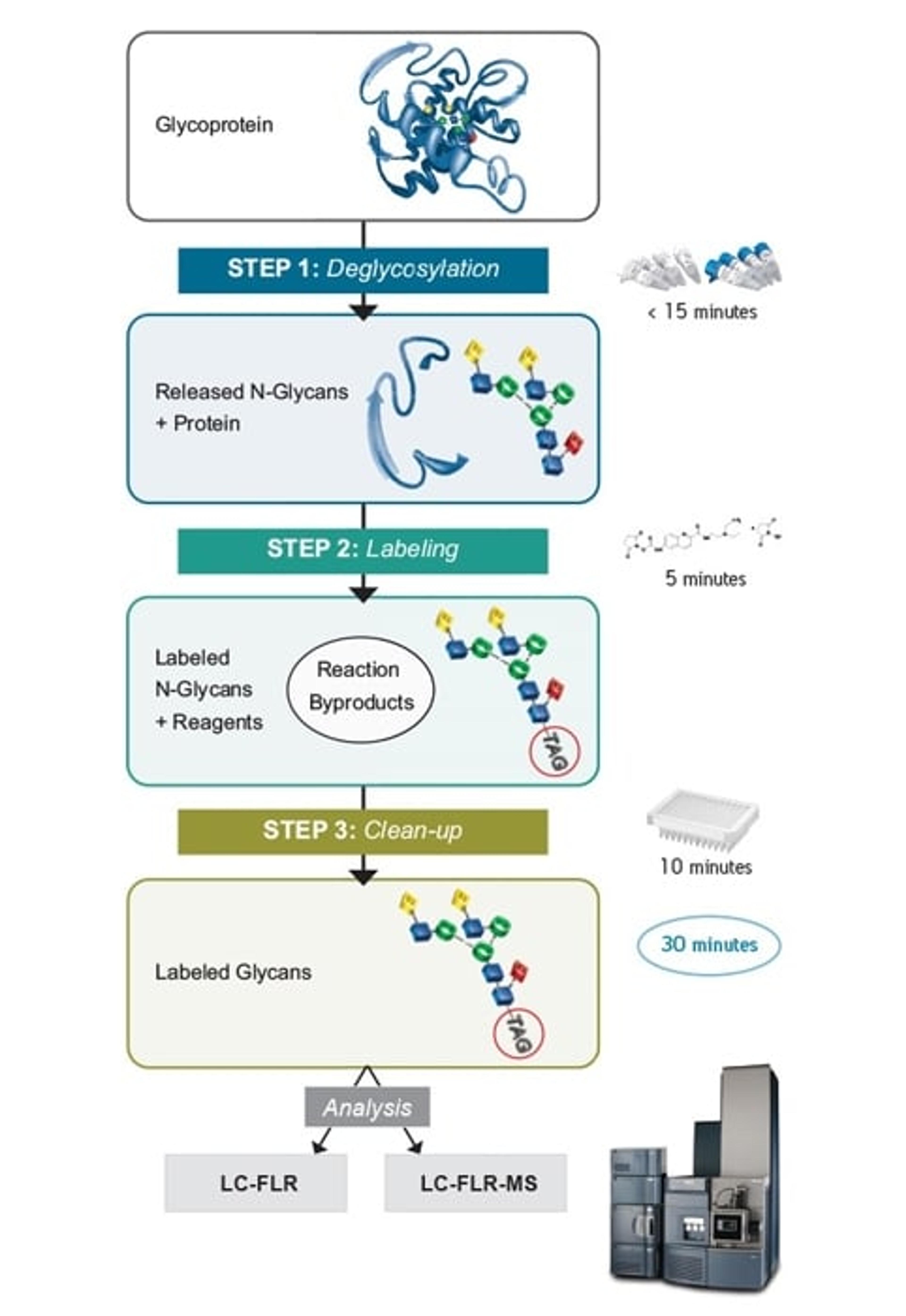

In a recent webinar, Danielle Cullen, Phillip Lambert & Jennifer Fournier from Waters Corporation discuss the automation platform-compatible GlycoWorks RapiFluor-MS N-Glycan kit for released N-Glycan analysis, a historically complicated and laborious process. A rapid and new protocol for the kit is presented and is aligned to various automated robotic platforms, such as Andrew Alliance and Tecan platforms, for highly reproducible results and drastically reduced method timescales to help streamline lab workflows at high sample density throughput.

Read on for highlights from the webinar Q&A session or watch the webinar on demand here.

Why did you need to create a brand new kit for automation?

JF: The answer is really volume. Outside of the Andrew Alliance, no matter what robotic platform you use, you need more liquid than is typically in most of the sample preparation kits available. What we wanted to do was to make sure that our users had enough residual volume, so that they wouldn’t have to order more than one kit to run through an automated workflow. Also, when you think of automation, really you want to do things faster. That includes not spending a lot of time at your bench making up all the reagents to go onto the platform. So, we now cover that within our automation kits.

Why and how are you providing the scripts?

JF: The fact is we did not sell an automation platform at Waters but we needed one.

We realized most of our users were probably conducting automation on platforms already in their labs. Therefore, we wanted to make sure that we provided them with flexibility to use their robotic platforms in their lab. As we were going through the verification and validation work that we put into the design of this kit, to make sure that it was reproducible, we realized that it could be very valuable to our users. The scripts therefore are great at giving you a head start. One of the key pieces in there are the liquid classes. Chemistry can be half the battle when scripting, so this is like gold dust when you’re automating a workflow. All of that is now included.

What is the biggest difference between the Andrew Alliance (AA) offering and the high-throughput automation options?

JF: That really comes down to how many samples you are running at a time. If you have say 6 -24 samples running through your lab, the AA is a great platform to use as there’s not a lot of prep needed. It’s easy to set up, you can use the existing kits by just loading the deck and the domino and press go. It’s simple and great for low sample numbers. But it is single channel so it’s not going to give you that added advantage of being faster. If you do have more than 48 samples that come into your lab at a time, that’s when a high-throughput robot such as a Tecan or Hamilton provides you the advantage of timeliness.

Shouldn't the automation results be better than the manual?

JF: We found that the manual method is actually very robust. Really the variability of the method is with the analyst doing the pipetting. One advantage that automation can provide, whether it’s the AA or a high-throughput robotic platform, is that some of those critical attributes, such as pipetting, heating as well as the vacuum manifold sample preparation cleanup step, are now precisely controlled. What we saw in original data published is that the automation method, no matter what platform, didn’t provide any variability in the results.

Watch the full webinar on demand or find out more about Waters Corporation sample preparation solutions.

Do you use any of the technologies mentioned in this webinar? Write a review today for your chance to win an Amazon voucher worth $400 or an iPad.