Webinar highlights - Perfluorinated and Polyfluorinated Chemicals in the Environment – What’s the Big Deal?

Explore the latest methods, regulations and testing techniques used in the detection of these compounds in drinking water.

24 Nov 2017

Charles Neslund, scientific officer at Eurofins Lancaster Laboratories Environmental and Zoe Grosser, marketing director at Horizon Technology, recently shared their expert insights into the presence of perfluorinated and polyfluorinated chemicals in the environment and their potential impact on human health.

Watch the SelectScience® webinar to learn about:

- The regulations surrounding perfluorinated and polyfluorinated chemicals

- Future-facing testing techniques and methods for these chemicals

- Analysis of drinking water

Watch the webinar on demand or read on for highlights from the Q&A session.

Is there a limit, or advisory level, for total organic fluorine?

Charles: Not that I’m aware of. There are some analytical techniques to potentially address overall PFAS contamination that look at total fluorine, such as PIGE (proton-induced gamma-ray emission spectroscopy), or absorbable organic fluorine combustion ion chromatography for screening of total PFAS contamination by looking at the fluoride content.

Do you think these types of measurements will be more often required in the future?

Charles: Yes. In fact, the New Jersey (USA) governor recently signed into law a regulated drinking water level for PFOA and PFNA, so they now have hard targets for these two compounds in New Jersey. This is opposed to the health advisories that the EPA (environmental protection agency) has, that only give general guidance. More states in the USA are looking to establish guidelines for regulating these compounds and classes of compounds like this. Therefore yes, but we’re still at the beginning of this journey.

Will parafilm used to temporarily cover samples kept in beakers have PFAS?

Charles and Zoe: In both our labs, parafilm isn’t used for virtually all the environmental testing. While aluminum foil has been evaluated, not enough time has been spent investigating the use of parafilm.

When would you choose SPE disks vs. cartridges?

Zoe: In short – cartridges are best used for small volumes of samples with high levels of analytes. They’re also typically the lowest cost option. Disks present the best option for large volume samples and allow loading at rates that are 10-20x faster than cartridges.

Disks allow for the preparation of all types of samples, including waste water, which typically plugs cartridges. Cartridges are normally used for drinking water applications. Use of disk pre-filters, glass wool and screens eliminate the need to perform multiple independent steps in preparing samples which adds time due to multiple independent steps. Using cartridges or 47mm disks does not provide the capacity for particles and matter in waste water samples. One alternative has been to pre-filter the samples and remove all the particulate matter. This requires additional independent extraction of the particles and rinsing of the bottles, followed by a combination of the elution. These extra steps add time, and reduce precision and recovery. Allowing use of large capacity pre-filters in line with the final disks allows even the most challenging samples to be handled without any exterior manipulation. Rinses and elution solvents are passed through all of the pre-filters and disks.

How do you minimize contamination?

Zoe: The issue of contamination usually increases with the number of manual steps in a method. This can be minimized using a piece of automated equipment, as it’s less hands-on, so you’re not manipulating the sample as frequently and therefore have less chance of contamination. In addition, if your instrumentation is free of Teflon and other materials that might contaminate your sample, then you’re going to keep it cleaner. A rinse of methanol before you run through your sample will also help.

With the SmartPrep® solution, is the whole sample used and the container rinsed for quantitative transfer of potential analyte?

Zoe: Yes. The SmartPrep® automated cartridge extraction system is a flexible piece of equipment, so it can be set up in different ways. It can work using the whole sample and rinsing the container, so there should be nothing left sticking to the glass.

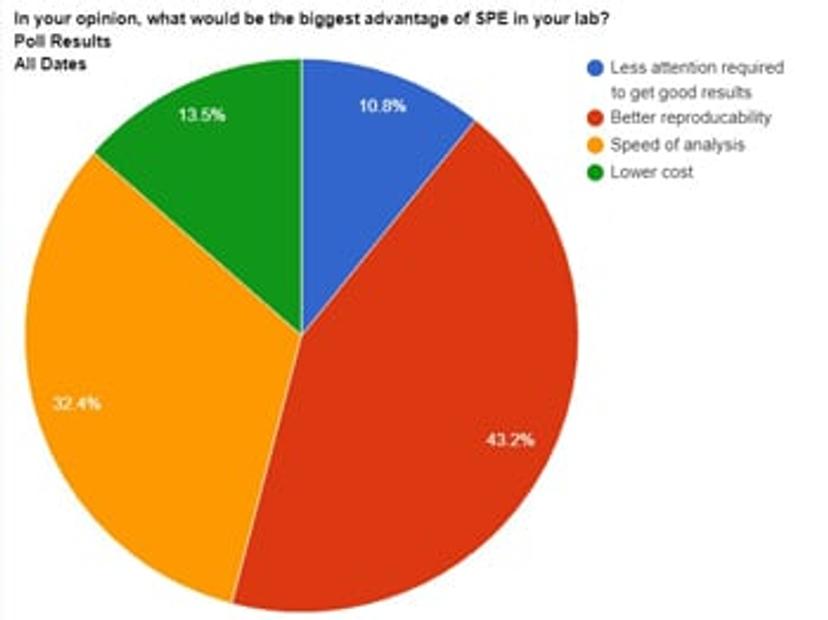

In an attendee poll held during the webinar, we asked:

‘In your opinion, what would be the biggest advantage of SPE in your lab?’

The results showed that:

- 43.2% of the audience thought that better reproducibility would be the main advantage of using SPE in their lab

- 32.4% felt speed of analysis was the biggest factor

- 13.5% suggested lower costs was the main advantage

- 10.8% said that less attention required to get results was key for them

Charles and Zoe: Reproducibility is a critical factor, and many labs think speed of analysis is key. Getting better, consistent results over the long term, however, is a great parameter to gauge against.

Watch the full webinar on demand, or find out more about the technology enabling this work.