All-encompassing connectivity: The cornerstone of digital transformation

In this guest editorial by Thermo Fisher Scientific, learn about the steps you can take to unleash the power of digital transformation to optimize your scientific workflows

19 Jul 2022

Digital technology continues to rapidly advance, offering solutions to help scientists in the pharmaceutical laboratory work unrestrictedly and foster new collaborations. From electronic notebooks (ELN) to automated incubators, nearly every aspect of the traditional laboratory workflow is being optimized through digital transformation for faster results.

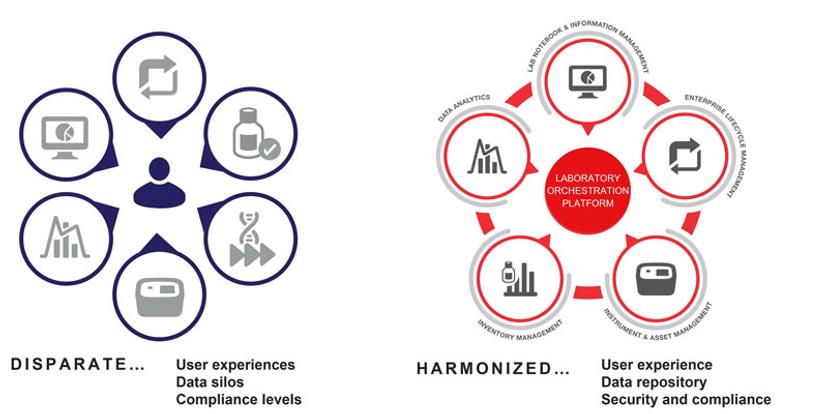

Yet many laboratories suffer from disconnection of these technologies and processes. Data is siloed in disparate systems and is not prepared for advanced analytics. In addition, disconnected systems mean downtime cannot be planned as there is no instrument maintenance visibility. Talented scientists must work across these multiple systems and have limited opportunity to collaborate. Finally, their productivity is limited as their schedules are packed with manual tasks.

To truly realize the full potential of digital technologies and accelerate their science, organizations need to ensure that their systems, processes, and people are connected and working harmoniously. Only then can they enjoy a complete scientific ecosystem where data can seamlessly flow. A ‘connected’ laboratory eliminates much of the manual laboratory work, allows samples and associated metadata to be managed effectively, and readies data that abides by the FAIR (Findable, Accessible, Interoperable and Reusable) data principles for use by analytics tools.

For those on their digital transformation journey, it can be daunting to begin connecting the laboratory. By taking considered steps, you can start to join the dots and unleash the power of digital transformation to optimize your scientific workflows.

Breaking down the laboratory ecosystem

Unlocking the power of digital transformation to deliver faster results and get the most from your data requires three key steps:

1) Connect everything: Analyze your existing infrastructure to see how you’re really working. Do you have a disconnect between your people, processes, and data? This is one of the most important steps to address, as only by uniting these elements can you make data available when and where it is needed.

2) Automate end-to-end workflows: Identify areas for optimization to automate workflows, accelerate science and drive laboratory productivity.

3) Leverage advanced analytics: Adopt advanced data analysis, visualization and artificial intelligence (AI) solutions to use your data in new and exciting ways.

Now, new software and solutions are emerging to bring connectivity to the laboratory and better facilitate the digital transformation journey.

Integrating your instruments

Workflow automation has been widely adopted in the pharmaceutical industry over recent years with the main driver being connecting data for end-to-end traceability. But achieving this connectivity requires integration of both internal and external services such as lab information management systems (LIMS) and ELN. This integration allows bi-directional data transfer, meaning a particular workflow can be initiated based on up-to-date sample information.

This can be challenging to successfully execute, though, as instruments and software from different suppliers are not designed to effectively communicate with each other. Now, software can bridge the multi-vendor gap to facilitate data sharing across multiple systems regardless of supplier, and allow direct communication between technical teams. Thermo Scientific™ Momentum™ Workflow Scheduling Software, allows users to receive and initiate requests with external services in real-time so results and instrument status can be monitored remotely, instruments can be controlled according to defined processes, and methods can be updated on-the-fly.

Deepening connectivity, harmonizing workflows with orchestration

While integration of your instruments for end-to-end workflow scheduling is a critical step towards a connected lab, deeper, comprehensive connectivity demands an altogether more complex solution – an orchestration engine. Orchestration engines utilize transformational data layers to bring together all components of your science – workflows, people, services, equipment, and consumables – across R&D, clinical, and manufacturing settings. The Thermo Fisher Connect Platform securely connects all of these different and disparate aspects, across geographies and functions, and makes them accessible through a single, clean platform dashboard. Management of complex, multi-component processes thus becomes simplified, compliance less taxing, and most importantly, data becomes more fully available to unlock the power of advanced analytics (see Figure 1).

Elevating your science through connectivity

Connecting the laboratory accelerates and simplifies digital transformation. Whether you’re a lab analyst, lab manager, or system admin, connecting your workflow can help by automatically transferring data, reducing manual tasks, and saving time. Therefore, it is vital that organizations invest in connectivity and adopt these approaches if they are to digitally transform their laboratory and take their science to new levels.

Integration and orchestration software can aid this journey and make data available for easier analysis. However, with many options available, it bears remembering that every digital transformation journey is unique – there’s no one-size-fits-all solution. To gain the most from your data, working with a partner who offers flexible solutions can streamline your transformation and guide you down the path that’s right for you, revealing greater productivity and unrealized opportunity.

Visit our new special feature to find out more about the latest advancements in lab automation.