Going green in the plastic lab

How Labcon’s adoption of the ACT label is helping scientists reduce the environmental impact of their labware choices

6 Sept 2021

While a growing number of scientists are trying to limit the environmental impact of their research, most benchwork still depends on plastic consumables, making sustainability challenging. Some suppliers and manufacturers have worked to improve the green credentials of these critical consumables, but the difficulty in comparing similar products has made it hard to be certain which labware is the most eco-friendly. A new product evaluation solution, the ACT label, can change the way scientists purchase sustainable labware. In this exclusive SelectScience® interview, Scott Weitze, lead scientist at Labcon, tells us more.

Laying the path to greener research

Based in California, USA, Labcon is a leading manufacturer of low-carbon laboratory disposables with a longstanding commitment to reducing the environmental impact of its operations. “Labcon’s mission for improved sustainability goes back as far as 1994,” Scott tells SelectScience. “At this time, we started looking at alternative options for racking tubes and packaging tubes, and this got us thinking about how we could reduce all the auxiliary things that come with our plastic products, from manufacturing to end-use.”

Over the past 20 years, Labcon has taken industry-leading steps to improve the design of its products, promote reusability, and reduce its energy consumption, greenhouse gases, and waste. Highlighting a few key achievements, Scott summarizes: “In 2004, we moved into a new facility in Petaluma, Sonoma County California. In Petaluma, we perform all of our operations, including product design, manufacturing, packaging, and sterilization. Many other companies only manufacture parts overseas. Even the remaining domestic manufacturers will ship parts to sterilization facilities and packaging facilities in a different county, state, or even across international lines. We perform everything in one place, meaning there’s no extra transport and no additional greenhouse gases from transport.”

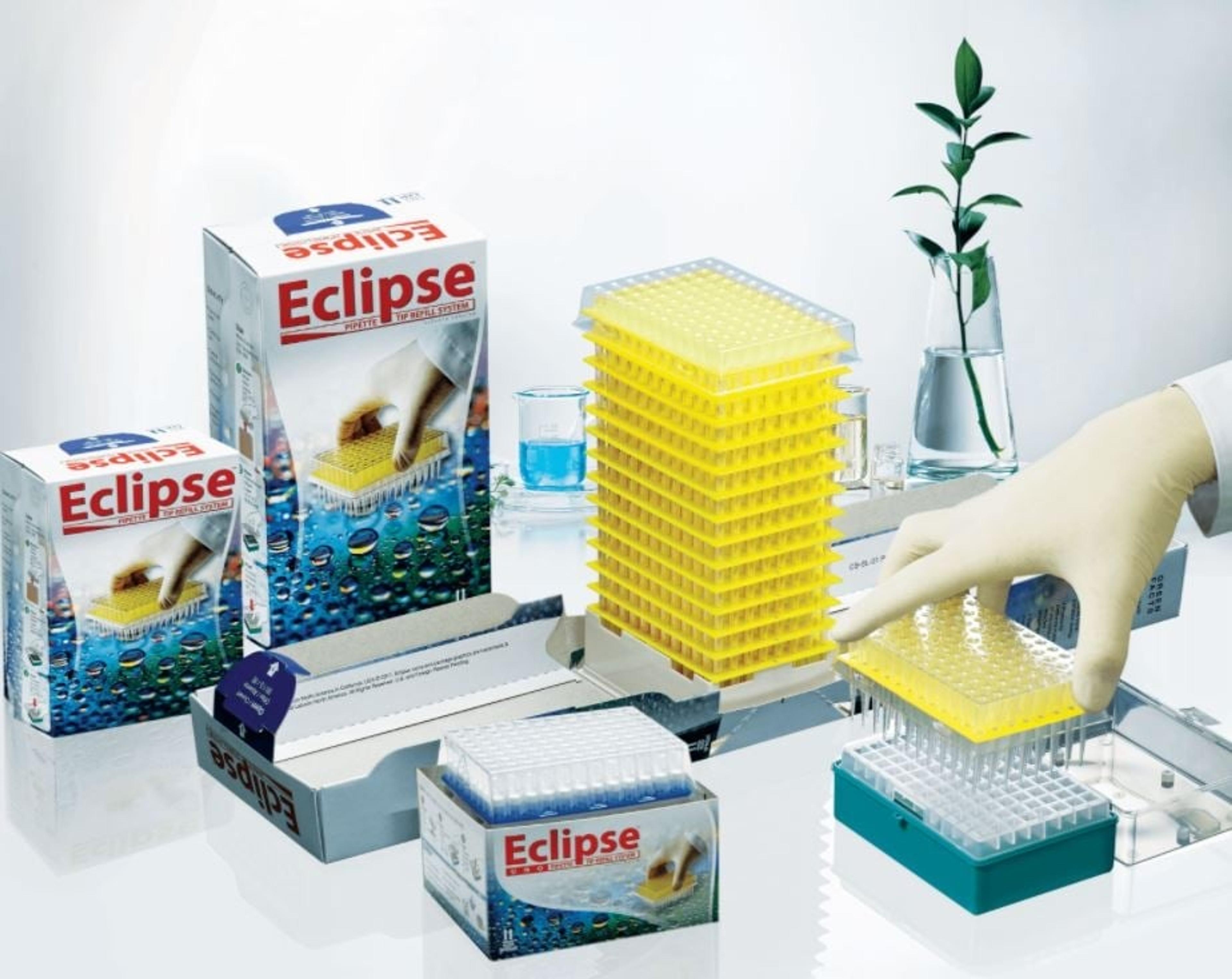

He continues: “In 2011, we put up an 870 kilowatts solar facility, and by 2015 we had partnered with the Environmental Protection Agency as a green power supplier and had started to source the remainder of our energy locally from Sonoma Clean Power. This allowed us to use 93-97% clean energy for manufacturing in our facility. In 2017, our commitment to reducing packaging waste and creating reusable lab products, such as our Eclipse Pipette Tip Refill System, was recognized by receiving The Golden Arrow Award from the California Product Stewardship Council, which we’re very proud of.”

Enter the ACT label

As its latest green commitment venture, in 2019, Labcon officially registered with the ACT Environmental Impact Factor label from My Green Lab. Standing for Accountability, Consistency, and Transparency, the ACT label takes a holistic look at the multiple aspects of sustainability surrounding lab equipment, gives a score for each, and then calculates an overall rating – called the Environmental Impact Factor (EIF). This takes into account factors such as whether a manufacturing facility uses renewable energy, the impact of shipping a product to the lab, what a product is made of, as well as its packaging, lifetime rating, and disposal. The label employs a simple scale of one to 10 for each subcategory, in which one represents the least environmental impact and 10 is the highest, worst impact.

Scott adds: “Using the ACT label, customers can easily compare our products to those from different companies, or even between different products from Labcon, and make choices based on the environmental impact factor, which essentially provides an analytical score for how sustainable a product is.”

A cheat-proof auditing system

Products certified with the ACT label are independently audited by SMS Collaborative, LLC (SMSC) and published by My Green Lab. “My Green Lab essentially has a scoring rubric for each of the different subcategories within the ACT label score, and we provide them with all the raw data,” says Scott. “As the audit is performed independently, any other company using ACT labeling for their products has to go through the same process, allowing for a very fair comparison of products.”

Labcon has reduced its energy use by 58%, greenhouse gas emissions per case of product by 89%, water use by 81%, and waste by 86%. The ACT label helped us take those numbers and show our customers how we achieved them

He continues: “Whereas many manufacturers of biotech devices have only just started to move towards sustainability, Labcon has been implementing measures for over two decades, so it was really nice to see that our efforts align well with how ACT scoring quantifies sustainability. Since 2000, Labcon has reduced its energy use by 58%, greenhouse gas emissions per case of product by 89%, water use by 81%, and waste by 86%. The ACT label helped us take those numbers and show our customers how we achieved them.”

Following the company’s first round of ACT labeling, the response to this initiative has been overwhelmingly positive. “We’ve seen a ton of enthusiasm from customers, and this is important because they are at the forefront of driving manufacturers to make sustainable changes,” says Scott. “We have customers that have purchased from Labcon specifically because we've gone through the ACT auditing process and because we’re trying to be as open as possible about how much they can improve the environmental impact of the products they purchase.”

Future outlooks

Building upon this success, Labcon has recently finished a second round of ACT labels, due to be published imminently. “In this second round, many previously labeled products will now also have the ACT UK Label and ACT EU Label,” says Scott. “We've also added several other products that were not in the first audit, including deep-well plates and tubes certified for shipping biological samples.”

Looking to the future, Scott suggests a shift in focus from recyclability to reusability could deliver big gains in lab sustainability. “Labcon makes our products as recyclable as possible and extremely well labeled for recycling, but we also have thought a lot about how to make products more reusable,” he says. “One of our main aims going forwards is to continue to design products that can be used multiple times while still functioning correctly in the lab environment,” Scott concludes.

Do you use Labcon products in your lab? Leave a review here for a chance to win a $400 Amazon gift card>>