Improving energy storage: What makes the perfect battery?

Learn about the latest methods advancing battery material research in this interview with Dr. Zhenyu Zhang, UCL

12 Sept 2019

While there is great focus on the development of renewable energies, efficient storage of such energy is also becoming increasingly vital. The development of new, more efficient batteries offers enormous promise for this.

Dr. Zhenyu Zhang, is a research associate at the University College London (UCL) Electrochemical Innovation Lab in the Department of Chemical Engineering, where he is currently researching battery materials. In his work, Zhang uses electrochemical atomic force microscopy (EC-AFM) to analyze surface morphology evolution of electrodes in electrolytes for the development of lithium-ion batteries. In this exclusive SelectScience® interview, Zhang describes what makes the perfect battery, the key methods used to elucidate the properties of battery materials, and how his research is helping develop the next generation of renewable energy.

When developing new batteries, what properties do you look for?

For the electrodes, we need better cycling stability and higher capacity. Currently, in the lithium batteries we use day-to-day, e.g. cell phone batteries, we use graphite and lithium-cobalt oxide materials for the anode and the cathode. These batteries have low capacity because we have reached the limit of these two materials. We’re now looking for other materials to replace these, such as silicon, and sulfur or lithium-nickel-manganese-cobalt-oxide. We’re interested in these materials specifically because they have higher capacity – meaning more charge can be stored - and they’re also more stable, both to the electrolytes and to the environment.

For the electrolytes, there is increasing study of solid-state electrolytes, because they’re safer and have better mechanical properties, which means you can use the high specific capacity lithium metal anode and alleviate lithium dendrite growth during charge/discharge cycling.

Which methods are key to researching battery materials?

My work is mainly divided into two parts. One is focused on electrode material, and the other is electrolyte material.

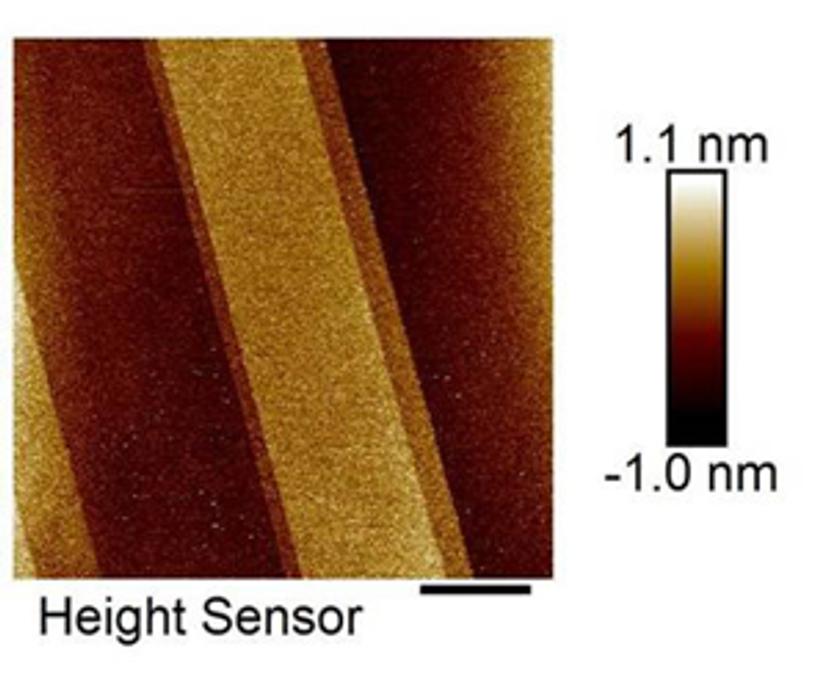

For electrode material, in order to obtain a flat surface for AFM study, I make powdered material into pellets and check the surface morphology of the particles during the charge-discharge process using electrochemical atomic force microscopy (EC-AFM). This technique enables us to scan the surface of the material to give an image.

Powder materials have very small particle scales, so I need to make the particles into a bulk platelet. To do this, I use the Specac Atlas Manual Hydraulic Press to make the powder into flat pellets. Based on the flat pellet surface, I can then capture the image and get other information, such as the electrochemical and the mechanical properties of each particle. I can also check the morphology evolution of the electrode during the electrochemical cycling.

For electrolyte material, traditionally, the liquid electrolyte of the organic solution is used. However, this is flammable, so to improve the safety and performance of the battery, we use the solid-state electrolyte. Solid-state electrolytes are typically made by polymer or ceramic materials. Ceramic electrolytes have higher conductivity and better mechanical properties, so I make these. To do this, I use the hydraulic press to make a flat pellet and heat it at high temperature, above 1,000 centigrade, to turn it into a sintered ceramic pellet, which can be used in the battery to improve the overall cycling performance.

What is next for electrochemical storage research?

Energy has always been a very hot topic, especially for universities and even in industry, because more and more people are using renewable energy storage methods to help to save the earth. In the ongoing and future research into electrochemical energy storage, finding new materials and designing novel structured batteries are the focus issues. Using advanced technologies to discover the degradation mechanism of batteries is also important, such as X-ray computed tomography and in situ electrochemical microscopy, etc., which is exactly what we are doing in our lab. These are all vital to improving battery performance and accelerating the development of next-generation batteries.

Learn more about UCL's Electrochemical Innovation Lab and Specac’s solutions for material research applications including the Atlas manual hydraulic press, or, for increased control of the pressing parameters, the programmable Atlas™ Autotouch hydraulic press.