Micromethods used for sample preparation aim to operate in the

microliter range. Instead of using milliliters of solvents or extracts in classical manual methods, only

microliter volumes are required. The PAL System is the industry standard for the automation of sample

preparation and extract delivery, designed for the automated liquid handling of microliter volumes in high

precision. Processing low micro volumes ideally fits the automated workflows of robotic sample preparation

using the PAL Systems.

The PAL System's automated workflows are compatible with established regulated

methods and can be applied directly to analytical instruments, both offline and online, for delivering prepared

extracts. After the automated sample preparation and extract clean-up stage, the PAL workflows can inject online

to the analysis instrument of the user’s choice, with microliter volumes. The next sample preparation or

extraction stage starts during analysis time, which has been precisely scheduled to be completed with the next

expected ready signal of the analysis system. Each sample is prepared on the same timeline for highest

reproducibility.

Liquid/liquid microextraction on the PAL System

When conducting trace analysis with small sample sizes, obtaining a representative

test portion from a bulk sample can be a significant challenge. Effective comminution and homogenization of

larger samples to smaller test portions are essential. For instance, in pesticide analysis of food samples,

cryomilling using a lab mill can produce reproducible and sensitive results with test portions as small as 1 g

6,7,8.

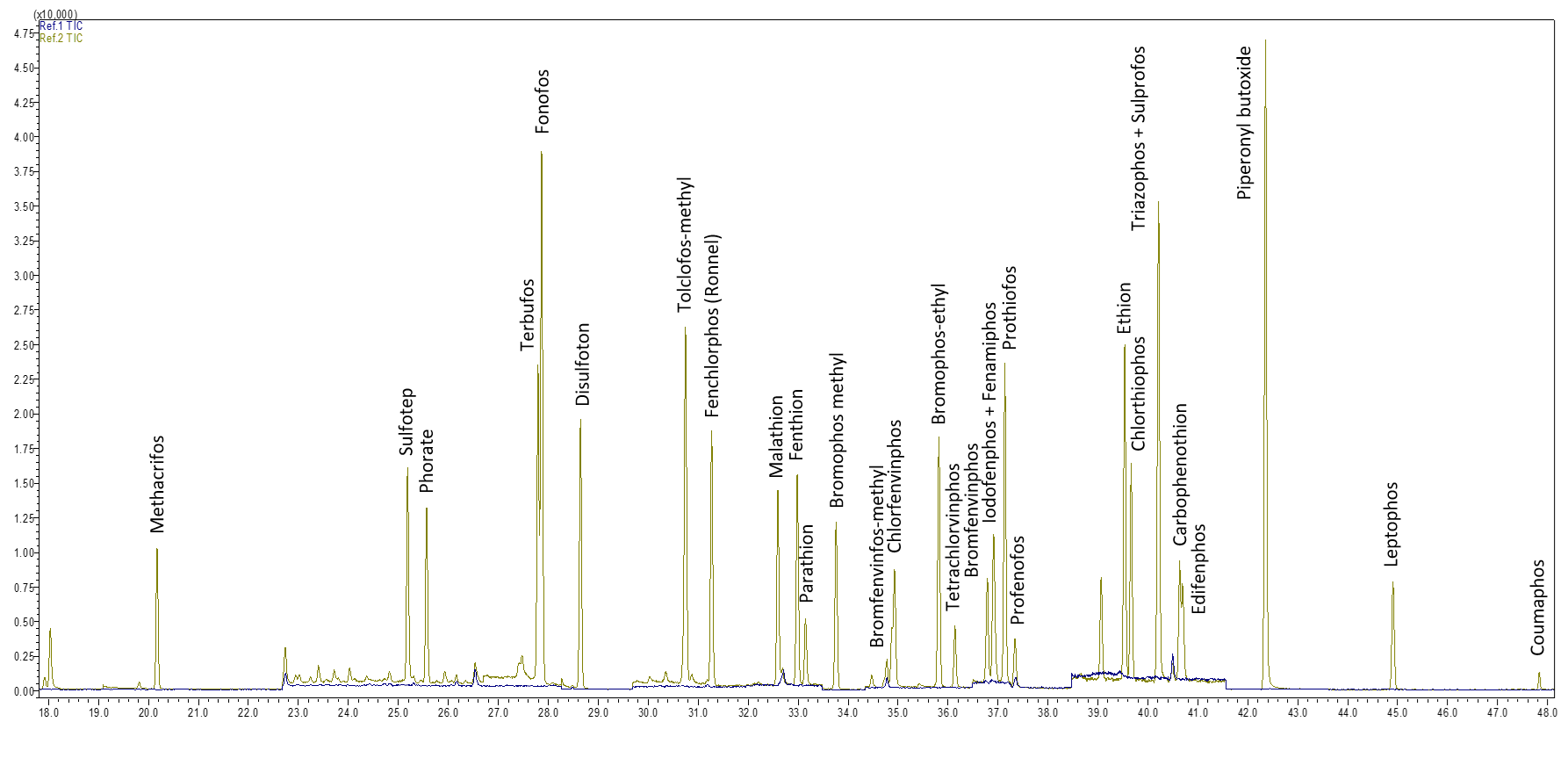

A

Orange juice sample in a 2 mL vial

B

Liquid/liquid extraction with acetonitrile

C

Cleaned extract for GC-MS and LC-MS analysis

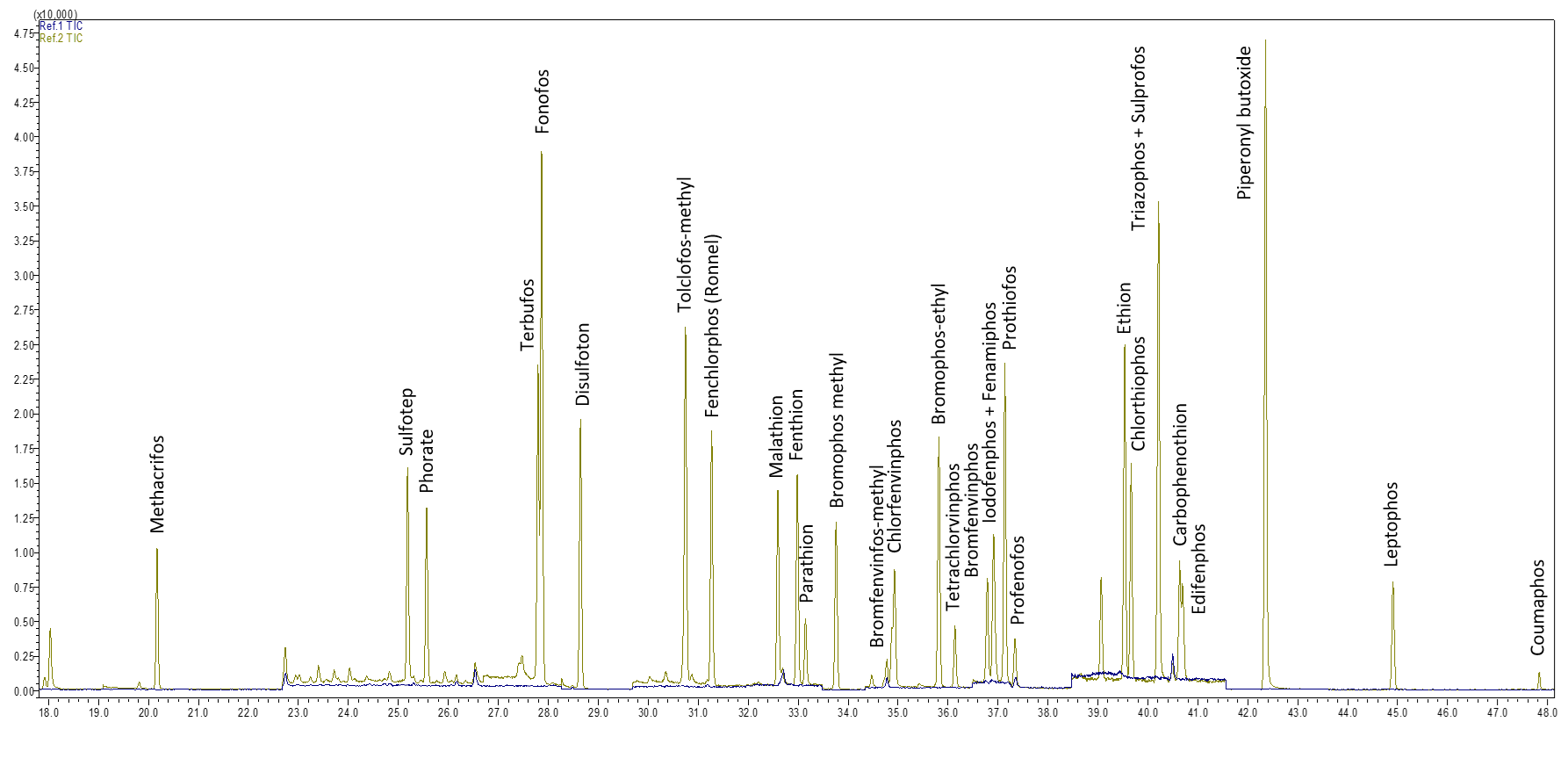

GC-MS analysis of a blank juice (black)and pesticides mix spiked sample

(yellow).

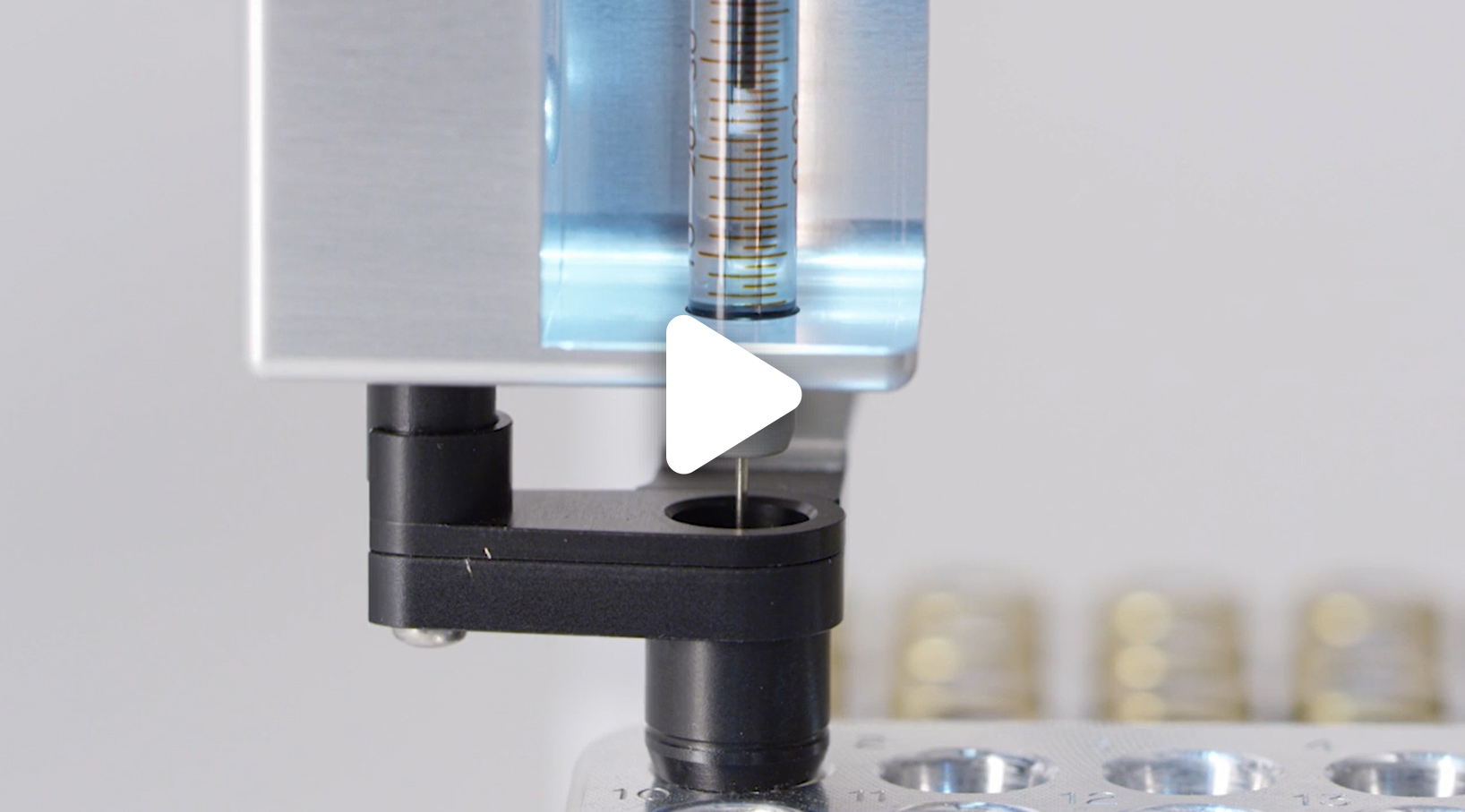

Micro-SPE applications on the PAL System

Micro-SPE has developed as the new standard for extraction, clean-up, concentration,

or filtration for automated green analytical workflows. The design of the new PAL µSPE cartridge allows for the

reliable automated processing with high sample throughput, accomplishing the principles of green sample

preparation.

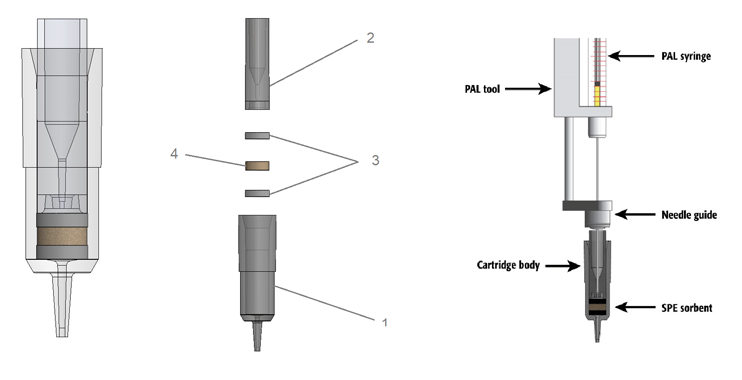

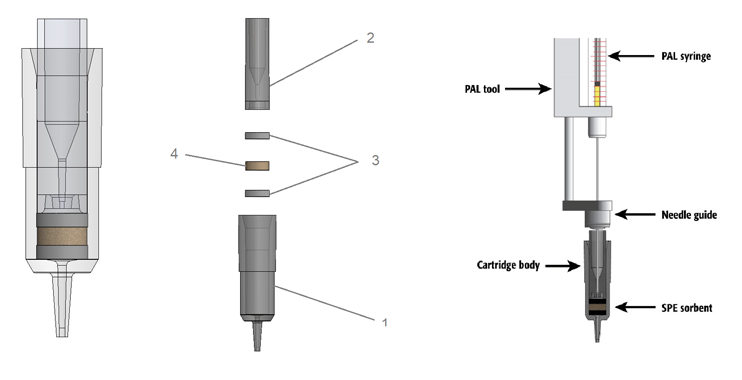

The new PAL µSPE cartridge consists of two parts (see figure below). The polymer

material used is chemically inert and free from leachables. The outer part (1) provides a higher capacity and

flexible volume for filter disks (3) and the sorbent material (4). The bottom outlet is designed to penetrate

pre-slit septa and to deliver directly to LC injection ports. The inner plunger (2) provides critical

functionality with the compression of the sorbent/filter layers, and a precise needle guide for safe and upright

transport. An essential feature is the ability to withstand high pressure and prevent leakage around the syringe

needle, which allows for faster loading of larger sample volumes. Applications range from food pesticides,

water, and drug analysis to forensic and pharmacological applications

The new PAL µSPE cartridge

The recent publication by Nicolas Michlig and Steven J. Lehotay9 (US

Department of Agriculture, Wyndmore PA, USA) evaluated the novel septumless µSPE cartridge with high extract

load flow rates in the range of up to 10 µL/s, using extract volumes of up 600 µL. More than 250 pesticides

were tested using the QuEChERSER methodology with LPGC-MS/MS analysis, which achieved recoveries of 80 to 120%

for more than 260 pesticides. Optimization experiments led to a routine extract load volume of 500 µL at 5

µL/s flow rate.

The evaluation of the automated clean-up using the novel PAL µSPE cartridge design

for multiresidue analysis of polar pesticides by LC-MS/MS was reported by Lorena Manzano Sanchez, Florencia

Jesus, and co-workers10 (EU Reference Laboratory for Pesticide Residues in Fruits & Vegetables,

Almeria, Spain). Improved recoveries were achieved for acidic compounds and sulfonylureas. A significant

increase in sample throughput, reduction of LC-MS matric ion source effects, and high reliability of the

automated method is reported.

Do micromethods work for both solids and liquid samples?

The trend towards micromethods, which can be used for both solids and liquids,

demonstrates a growing demand for these techniques within the analytical community. With an annual average of

more than 1000 publications for micromethods in sample preparation11 there is the strong

tendency towards miniaturization in all areas of chemical analysis12. These activities fit well and

support all endeavors for a truly green sample preparation in chemical analysis . The application of

micromethods with the PAL System can benefit labs in food, pharma, life sciences or environmental analysis

alike.

The best-known examples of automated sample preparation for volatile and

semi-volatile analytes (VOCs, SVOCs) are the static and dynamic headspace methods. However, are headspace

methods truly micromethods? By definition, they are. Although typically not named as micromethods, we often

subsume them as only small volumes of 'gaseous extracts' with less than micro amounts of analytes

taken from the sample vial for analysis, followed by direct chromatographic analysis.

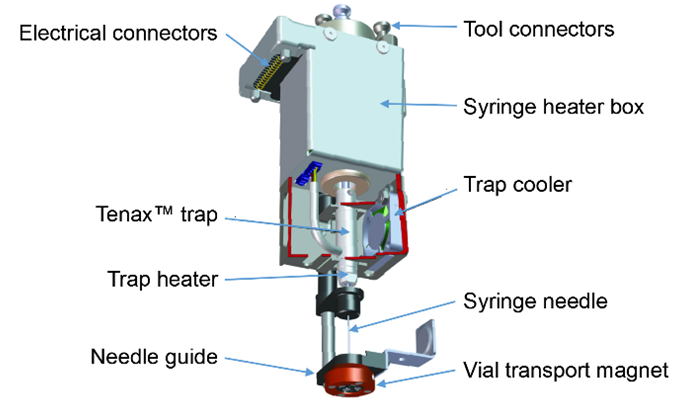

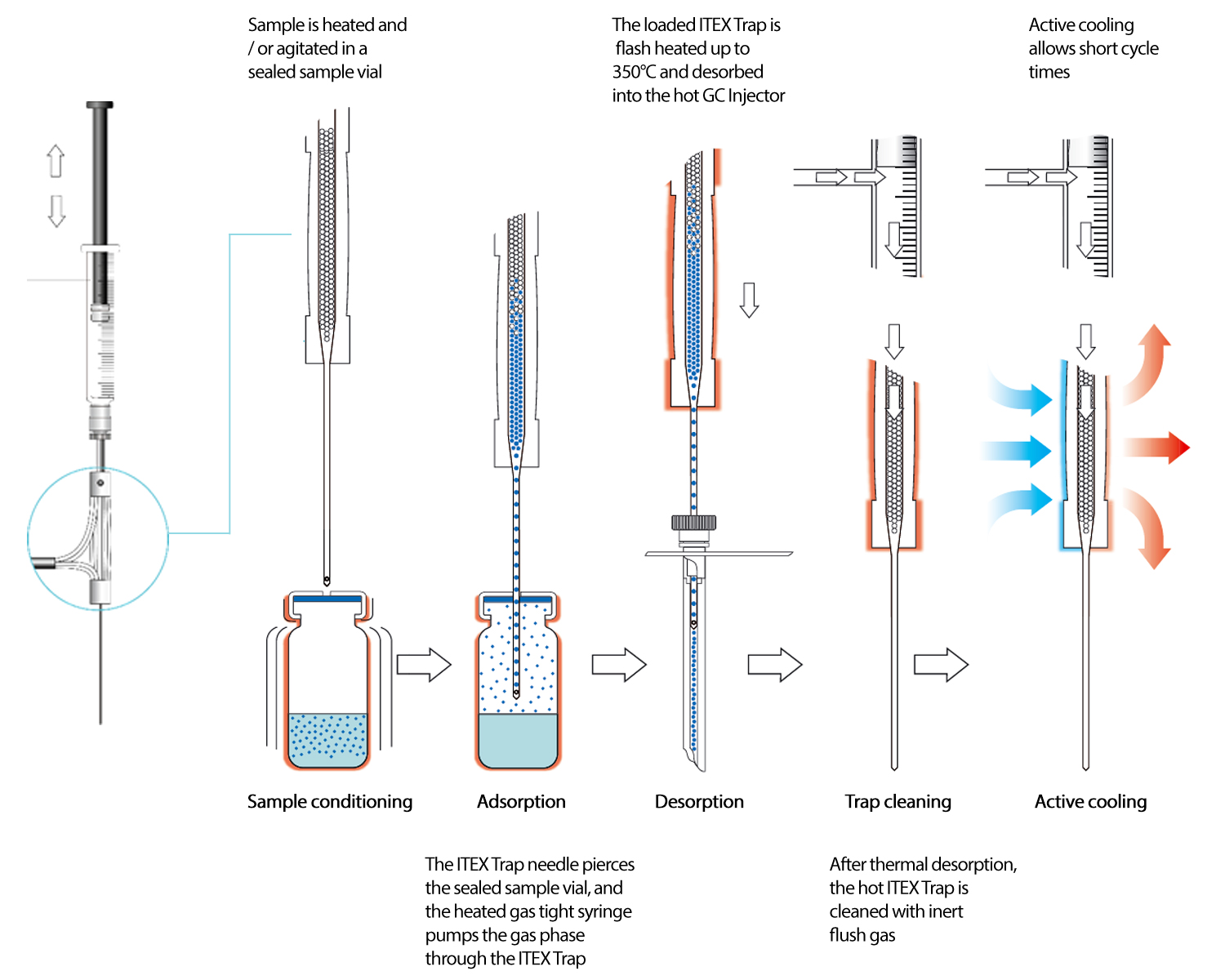

Switching from static headspace to dynamic headspace sampling couldn't be

easier on the PAL System. To do this, the user needs to simply place the dynamic headspace tool into the PAL

System (see graphics) and benefit from highest headspace sensitivity, even for important low-level compounds,

e.g. the odor intense sulfur compounds13.

Working principle of ITEX-DHS

SPME and SPME Arrow on the PAL System

SPME is a cornerstone microextraction technique whereby analytes are extracted from

a gaseous or liquid sample by absorption in, or adsorption on, a thin polymer coating fixed to a solid surface

of a fiber. SPME combines analyte sampling, isolation, and enrichment into one single step. After extraction,

the fiber is removed and inserted directly into a chromatographic instrument, usually GC or HPLC, for desorption

and analysis.

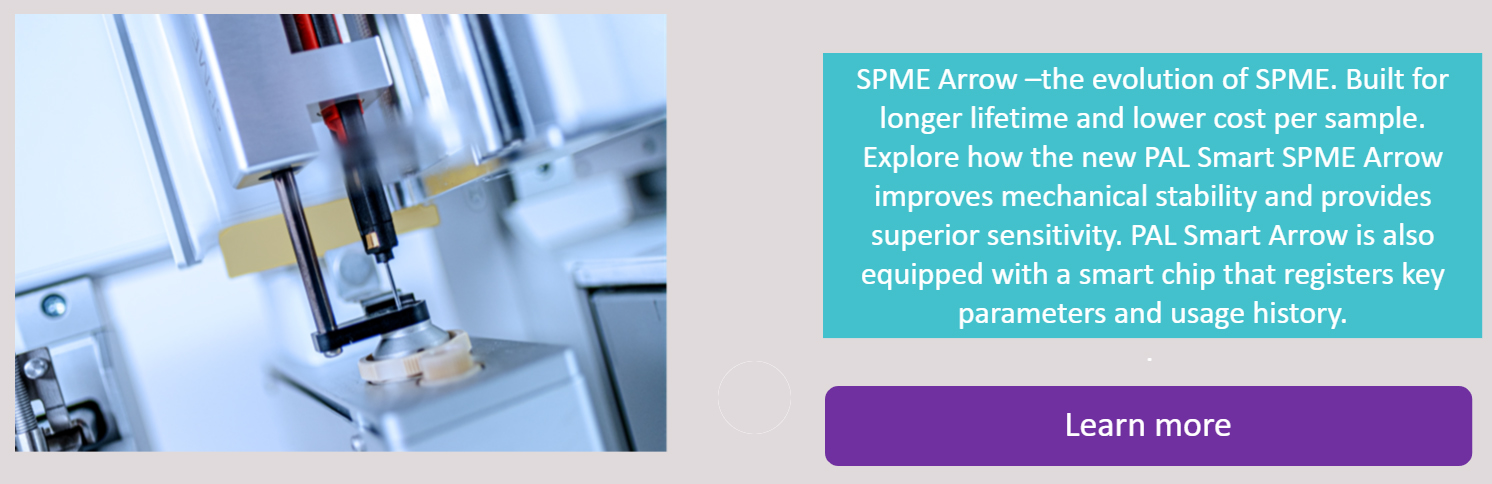

PAL System provides a wide range of SPME fibers as well as the more rugged and more

sensitive SPME Arrow device for routine high-throughput sample preparation.

SPME Arrow provides up to 10x more sensitivity compared to classical SPME, enabling

reliable and robust immersion extraction.

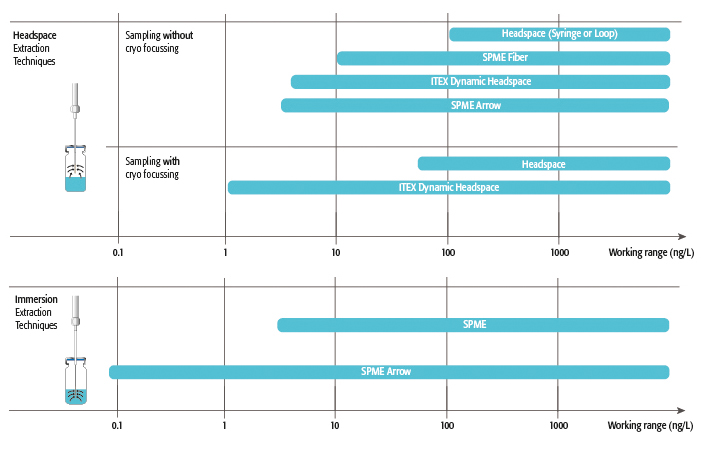

How do different extraction techniques compare?

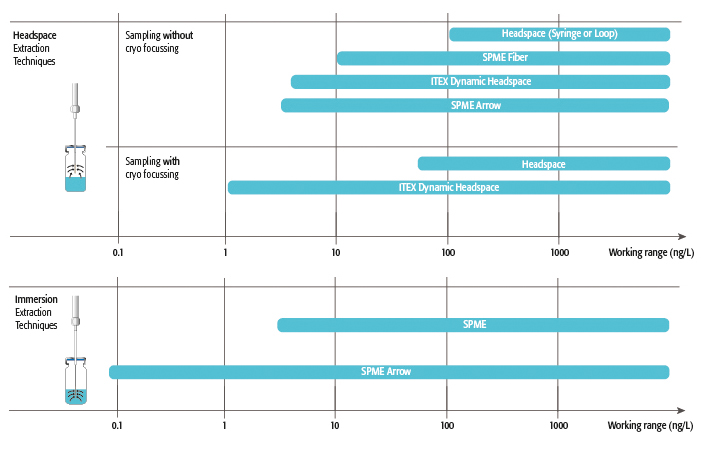

The diagram below outlines the working ranges of the different techniques for GC

headspace or immersion extractions.

How does the PAL System enable micromethods?

PAL Systems offer a wide range of tools, with static and dynamic tools available for

volatile analysis (VOCs). For example, the classical incubator and agitator is used for bringing the sample to

extraction temperature. A heated syringe is used for static headspace analysis. Dynamic headspace methods are

performed using a sorbent material filled syringe needle operated for extraction by the plunger strokes of a

heated syringe (ITEX DHS). Tenax TA™ or Carboxen™ materials are the typically applied sorbents with ITEX DHS for

the collection of the (semi) volatiles. The analysis is carried out by thermal desorption into a GC injector.

Solid phase microextraction (SPME) enables fully automated solventless extraction

procedures, with a variety of SPME fibers, along with the robust and sensitive SPME Arrow device. This is

utilized for high-throughput headspace sampling (HS-SPME) and direct immersion applications (DI-SPME) of both

liquid and gaseous samples.

Liquid extractions from solids (solid/liquid extraction, SLE) or liquids

(liquid/liquid extraction, LLE) are handled by the PAL System in compatible vial sizes, by adding solvent to the

sample with liquid syringes or dispensers, via thorough vortexing and thermostatization. The dispersive

liquid/liquid microextraction (DLLME) further miniaturizes the process to a true green microextraction with

lowest solvent use and improved analyte concentration14.

Many classical clean-up methods are using solid phase extraction. The PAL Systems

offer SPE micromethods for sampling, concentration, and clean-up of liquid samples. The use of micro-SPE

cartridges (µSPE) for enrichment, clean-up and even for filtration of samples significantly reduces solvent

consumption and preparation time and often improves recoveries15. The processing of the well-known

QuEChERS method with the extraction and clean-up are popular examples in this emerging application area. For

LC-MS applications, µSPE cartridges inject on PAL Systems with clean-up or filtration directly into LC ports,

saving precious processing time for increased sample throughput.

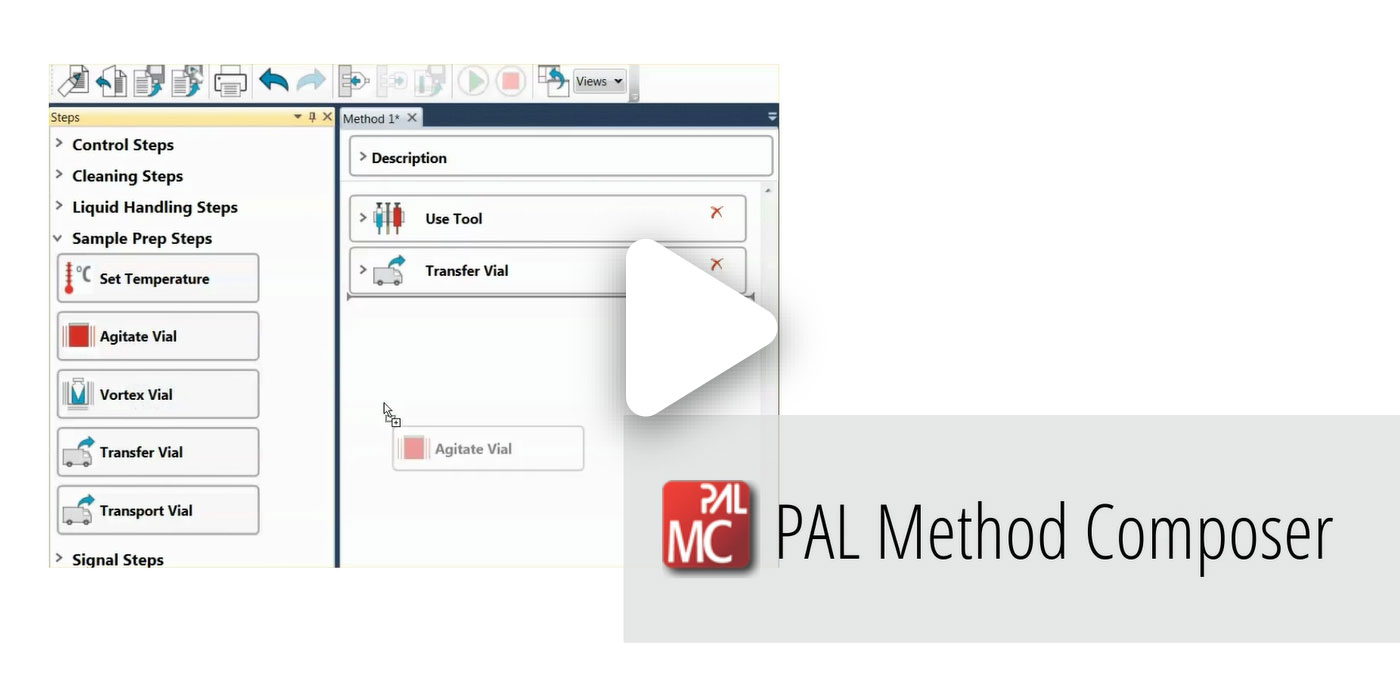

PAL Systems work in prep-ahead and overlapping mode to use the chromatography time

for sample preparation, significantly improving the sample throughput. Sensitive samples are treated all on the

same time scale ready for analysis without any waiting time, providing the required comparability of results for

larger cohort studies. Automated tool changes and parallel operation with dual heads extend the range of options

and offer sophisticated sample preparation workflows.

Additional devices and features support even more complex workflows. Cooling,

pipetting, dispensing, de/capping, or centrifugation are typical functions integrated into automated workflows.

Many PAL System partners offer additional functionality with, for instance, sonication, thermal desorption,

powder dosing, weighing or LIMS connectivity as well-known functions to complete proprietary workflows.