Compound storage plates for acoustic liquid handling

Cycloolefin and polypropylene microplates for sample storage

Polypropylene is still the material of choice for storage plates, but the material class of cycloolefins is becoming more routinely used because of its unsurpassed performance for a wide range of applications. In compound storage, plates made from cycloolefins offer the best combination of chemical resistance to polar solvents, like DMSO, and optical clarity. In addition, the dimensional stability and glass-like optical properties make this material ideally suited for plates in fully automated systems.

Microplates made from cycloolefin offer the following advantages in compound storage:

- Resistant against polar solvents such as DMSO

- Excellent water and vapour barrier function to minimise evaporation

- Nearly no extractables minimise leaching to avoid compound contamination

- Low biomolecule binding reduces the loss of compounds in storage and screening assays

- Glass-like optical properties for sensitive transmission and fluorescence measurements

- Superior mechanical stability and bottom thickness uniformity

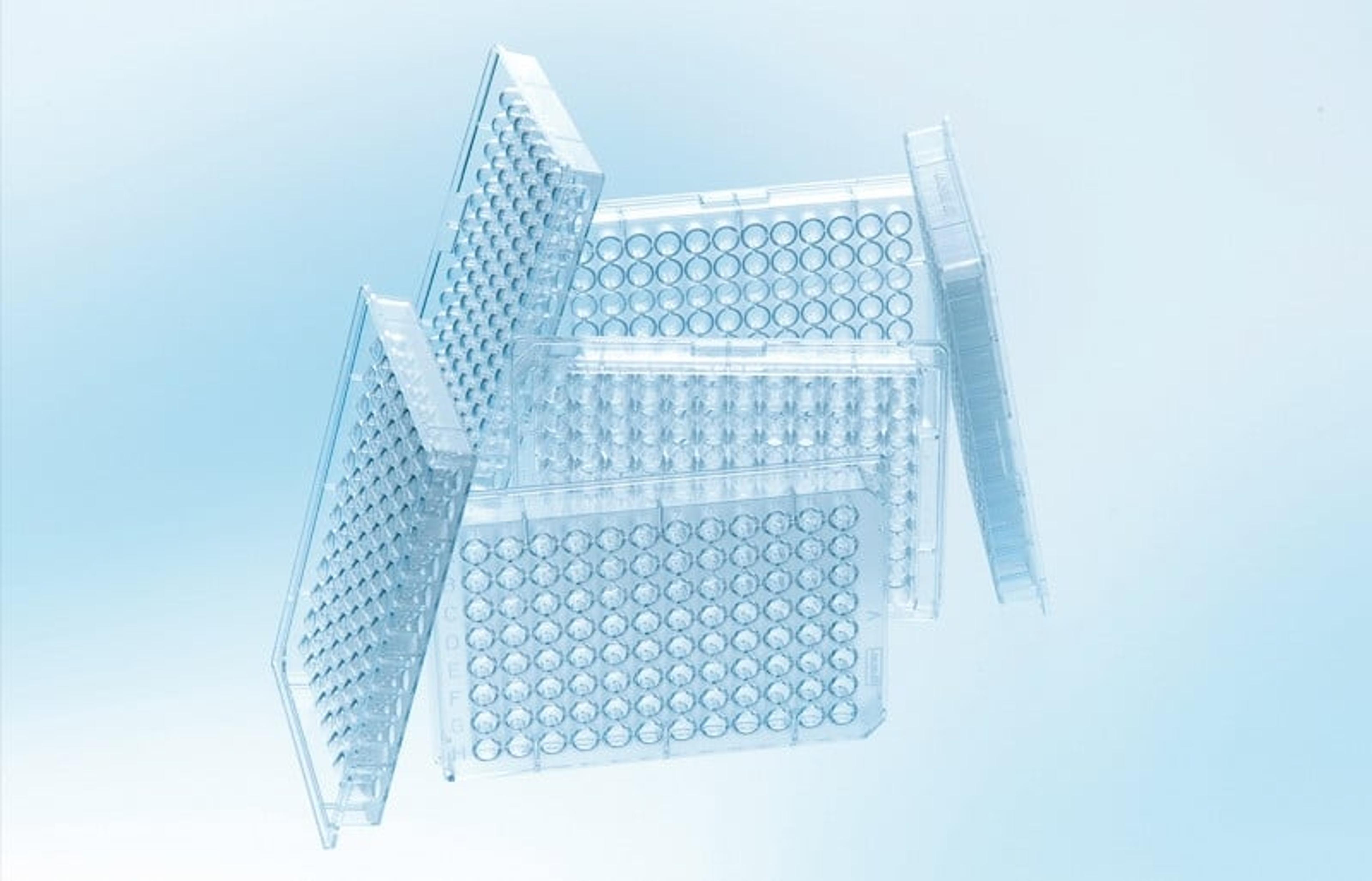

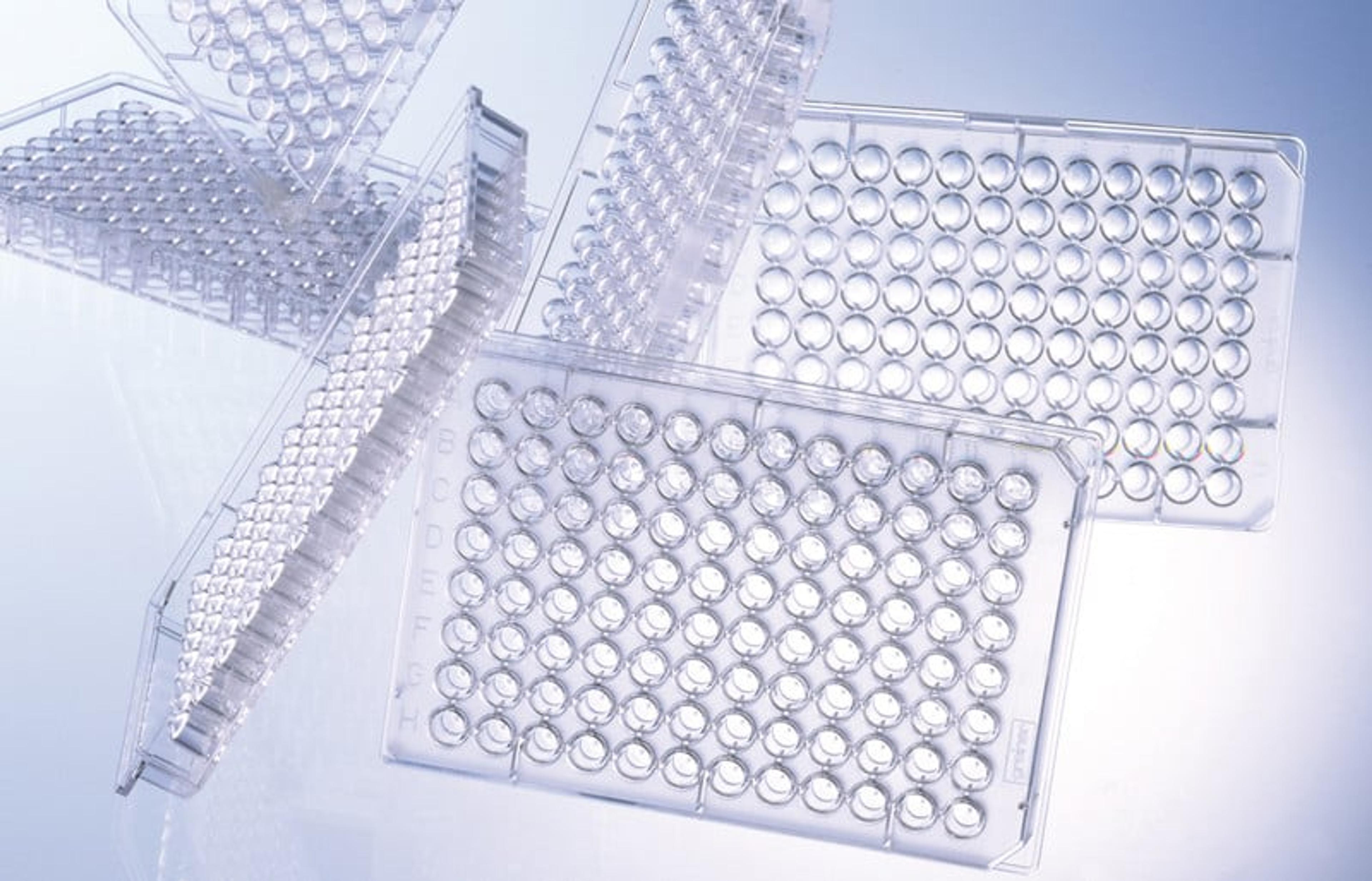

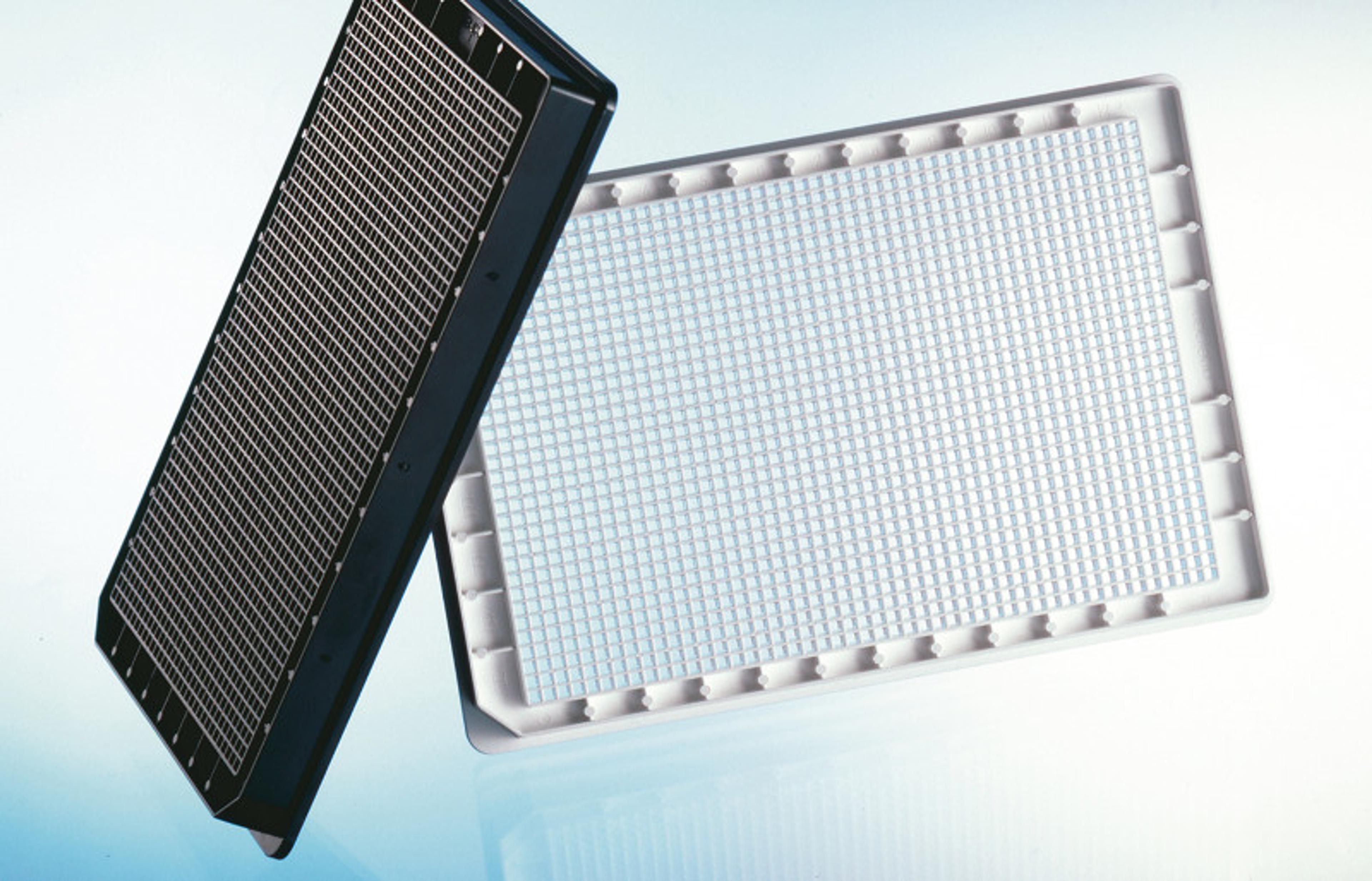

384 Well Polypropylene Storage Plate

The 384 well polypropylene microplates for acoustic liquid handling are the classic storage plates. They can be easily sealed using commercially available heat sealers and bind negligible amounts of proteins or active substances.

384 Well Small VolumeTM COC Storage Plate

The 384 well Small VolumeTM COC microplate reduces the dead volume in acoustic liquid handling. The standard 384 well grid of the microplate facilitates manual processing and visual control of individual operations.

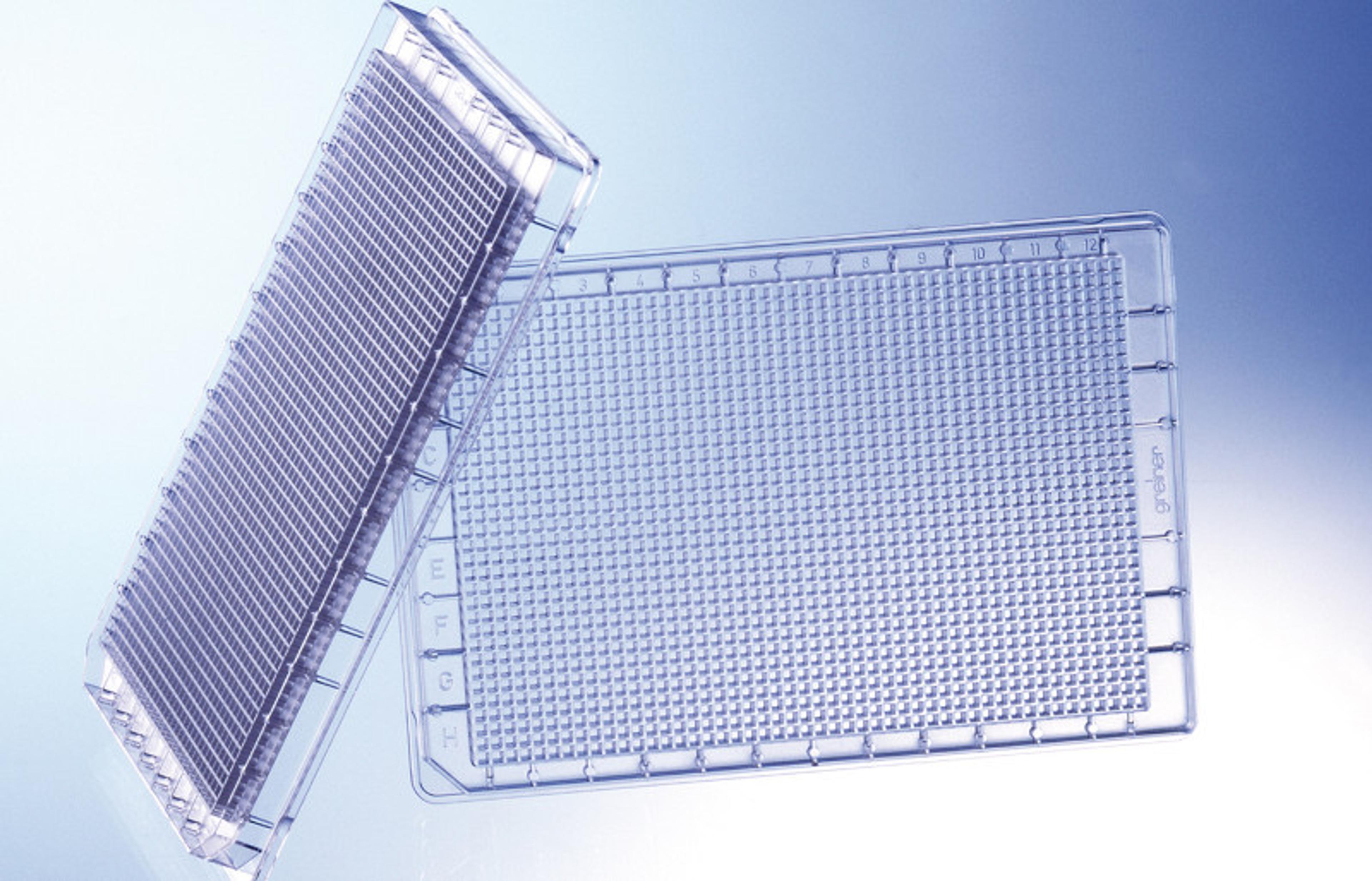

1536 Well COC Storage Plate

The 1536 well COC storage plate allows the storage of non-human sample material in the 1536 well format and reduces the dead volume in acoustic liquid handling. With a working volume of 1 – 10 µl this microplate is ideal for working with minimal sample volumes.

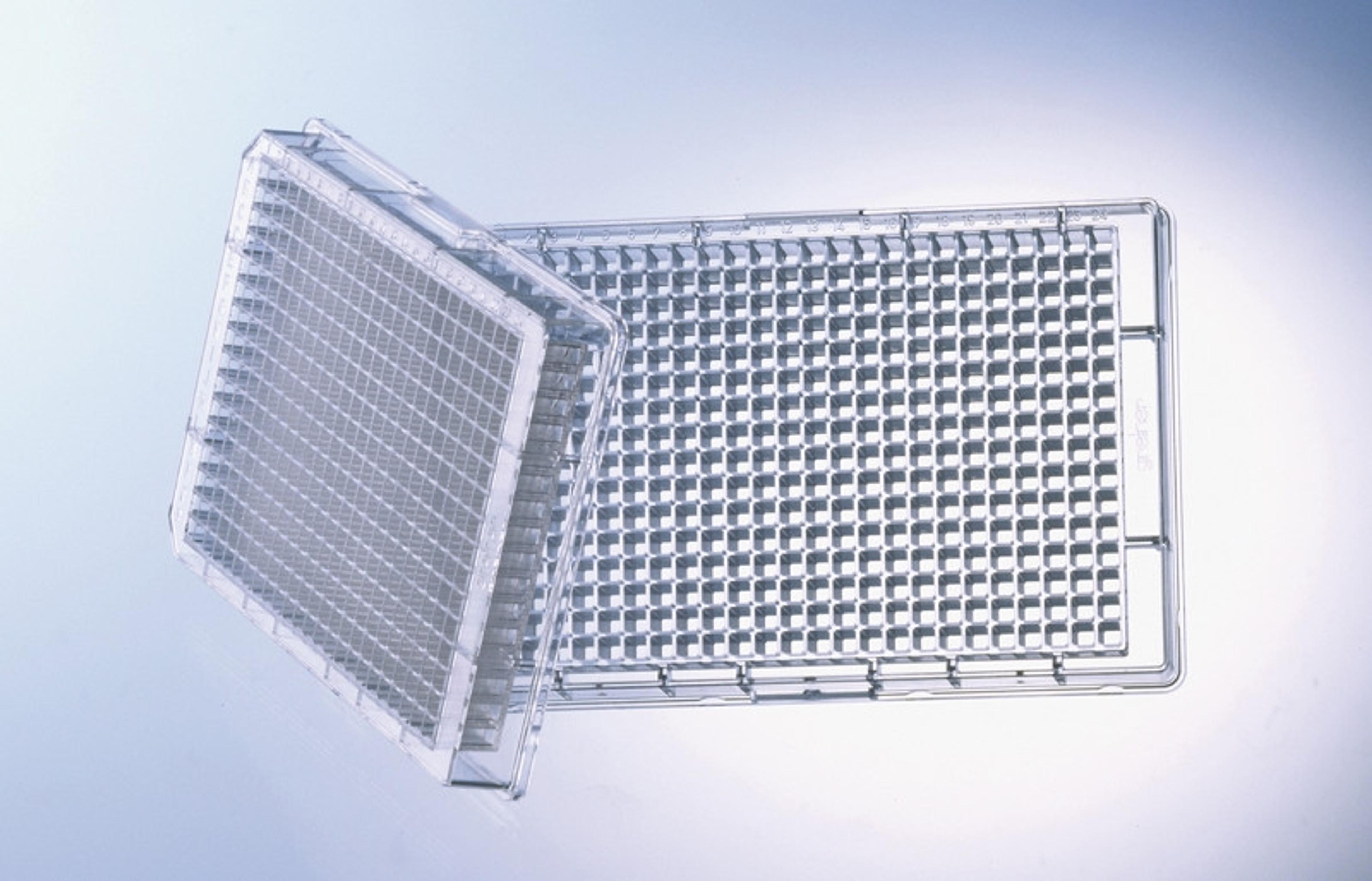

1536 Well COP Storage Plate with Optimised Geometry for Low Evaporation

The 1536 well COP storage plate with optimised geometry was developed in collaboration with Novartis AG, Basel, CH. The microplate features a continuous groove around the edges of the plate, in which a matching cycloolefin plate lid fits. This prevents evaporation and minimises edge effects.