Customized Solutions OEM/Customized Consumables OEM

By partnering with Eppendorf OEM, you benefit from our decades of experience in manufacturing high-quality consumables. We bring innovation to customization by tailoring our tips, tubes and plates to your exact specifications and needs, whether it's a small change or a full development from prototype to production. Trust our OEM experts to deliver scalable, customized solutions with high satisfaction. Trust our expertise.

Small changes make the difference – customized solutions and OEM

Eppendorf consumables are a synonym for quality and precision thanks to years of experience and most advanced manufacturing technologies. With our Customized Solutions we offer customized tips, plates and tubes tailored to your needs.

Customized automation tips

Our customized automation tips for your automated workstation are manufactured under extreme levels of precision and accuracy to meet the specific and varying expectations of our customers. Countless liquid handling workstations in the world work with Eppendorf conductive or non-conductive tips, benefitting from our high-quality standards. The tips are manufactured on automated production lines under clean room conditions (class 8), in a strictly validated and inspected ISO certified environment. Each tip is subject to stringent quality control in terms of critical dimensions. We build and maintain our own molds, ranging from 32 to 128 cavity tools. According to your requirements you can choose from generic tips or your own design.

We customize the tip to meet the specific and varying needs of our customers

- Special certified purity levels available carefully evaluated to ensure that they are sterile, pyrogen-, DNase-, RNase- and DNA-free

- Available in a variety of volumes and packaging options

- Optimal conduction for automated applications or non-conductive

- Tips are available with or without filters. Eppendorf innovative and high-performance filters made in-house

- Available in a variety of volumes and packaging options

- Predictable costs due to highly integrated supply chain and highly efficient automated manufacturing processes

Customized plates tailored to meet your unique needs

At Eppendorf, we understand that every customer has specific needs in terms of laboratory processes, workflows, and plates. That´s why we offer customization options, including:

- Customized barcodes for improved traceability

- Laser-engraved lot numbers and expiration dates on each plate

- Additional customized solutions adapted to your specific needs

Our customized plates are designed to deliver reliable, precise results for high-throughput applications, automated workflows, and standardized processes.

Eppendorf Tubes: The Optimal Choice for “Sample Integrity and Reliable Results"

We have a wide range of 15 tube product families, including the Safe Lock Tubes, 5 ml Microtubes, and conical tubes in 15-, 25-, and 50-ml variants. To minimize the risk of chemical leaching into samples, we avoid using any slip agents, plasticizers, and biocides during manufacturing. We also offer biobased tubes from 5 ml to 50 ml, all of which are produced with precise fabrication and the highest-quality materials for reliable results.

We offer different products for improved assay and cost performance:

- Special certified purity levels available carefully evaluated to ensure that they are steril, pyrogen-,DNase-,RNase- and DNA-free

- Amber tubes for light-sensitive samples

- DNA and Protein LoBind®

- Different volumes

Do you need a tube a little bit different? Contact our OEM experts.

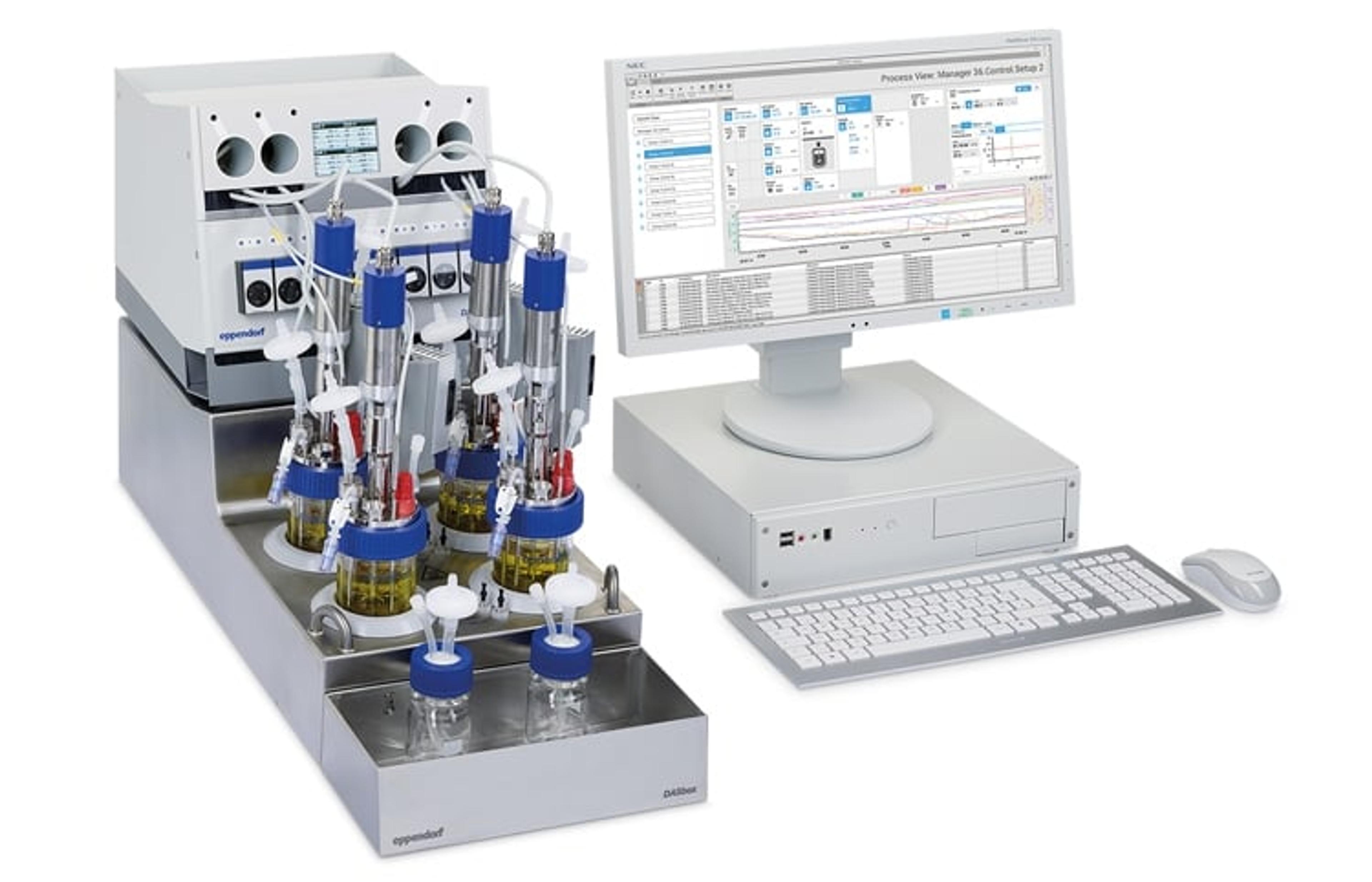

Premium quality for your OEM component

Having our own production facilities means that each one of your OEM consumables is manufactured to a high-quality standard. Benefit from our existing infrastructure and processes we use for our own premium products.

What we offer:

- Injection molding

- Automation technology

- Mold manufacturing

- High level of digitalization

- High purity levels

- Surface treatment technologies

- Certifications (ISO 9001, ISO 13485, ISO 14001)

Eppendorf consumables stand for superior quality and purity. This is achieved by the following:

Manufacturing using the pure raw materials:

- Fully automated production in clean room conditions

- Quality and functional checks of all lots

- Continuous quality assurance throughout the entire production process – from the initial material to the finished product