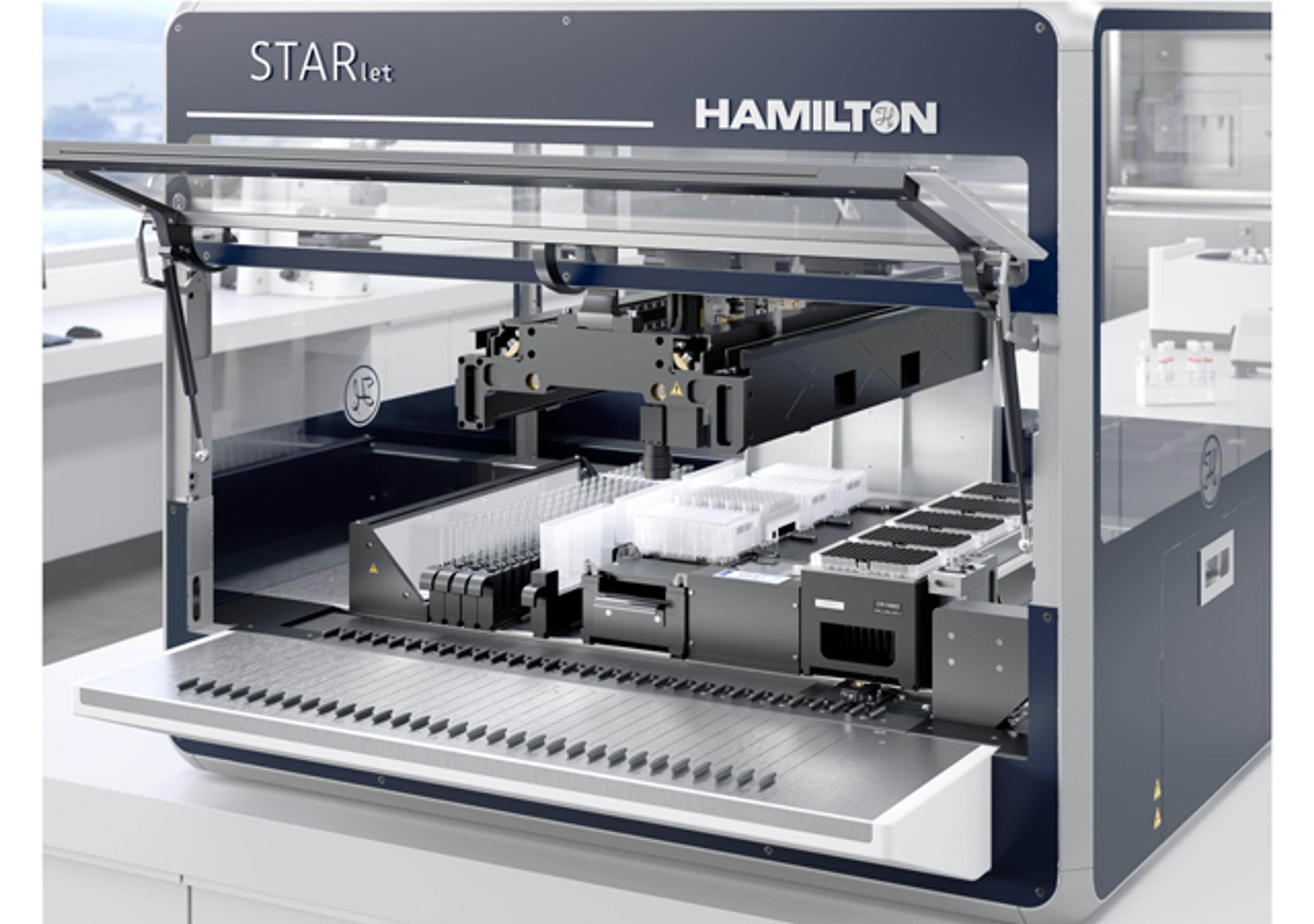

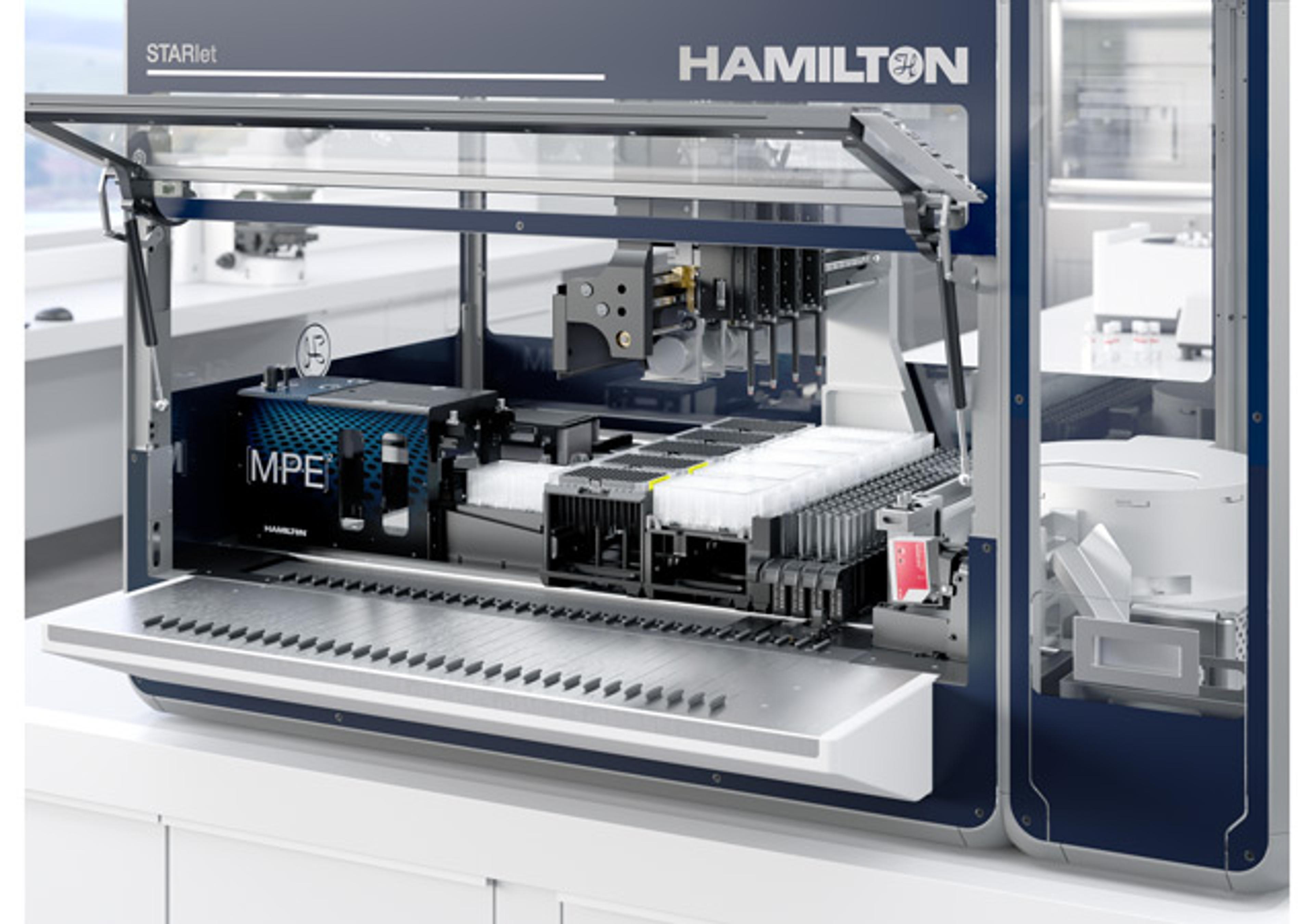

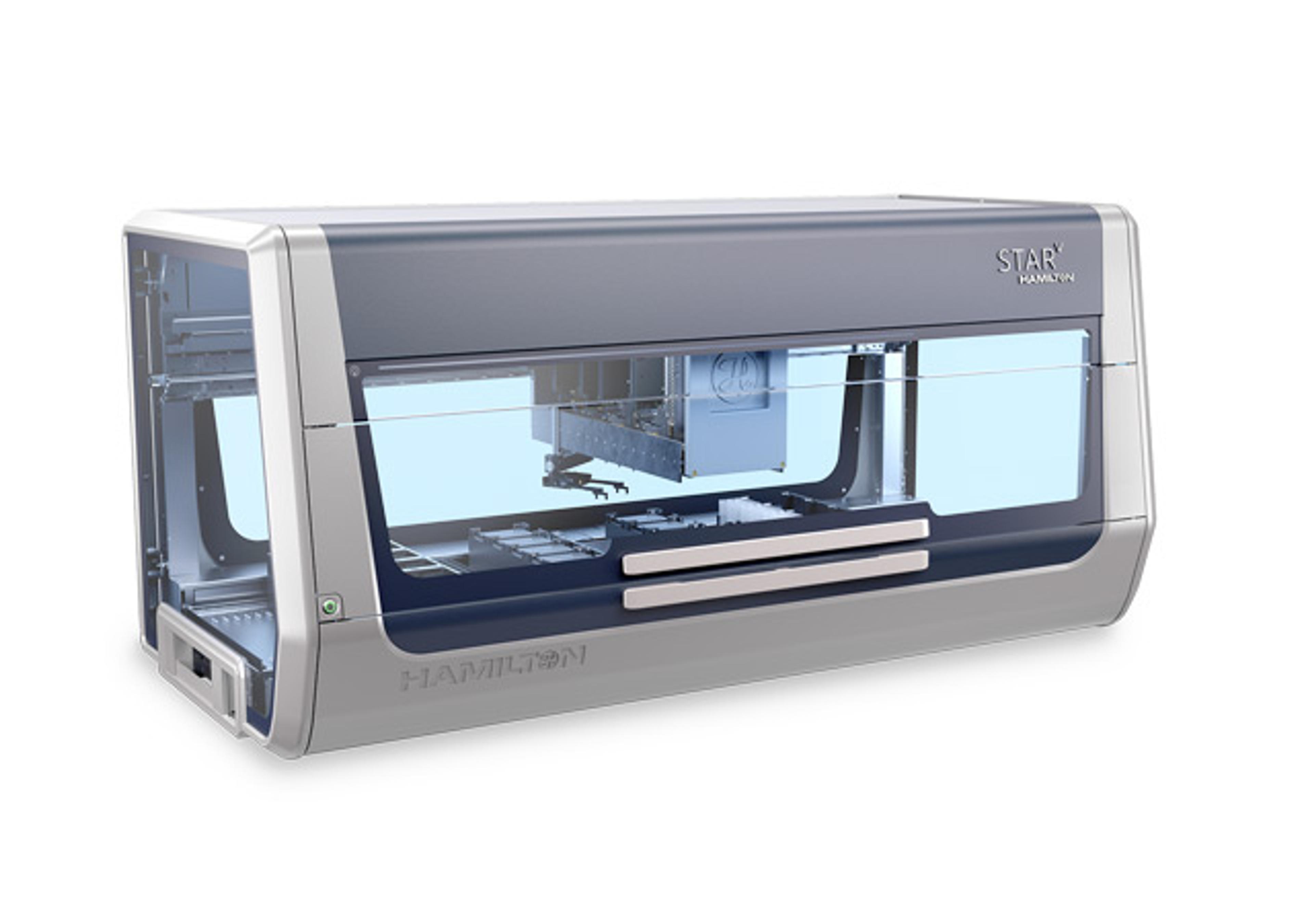

easyPunch STARlet

Consistent, Traceable Sample Card Processing. The easyPunch STARlet provides everything needed for hands-free sample card punching and extraction, along with sample traceability.

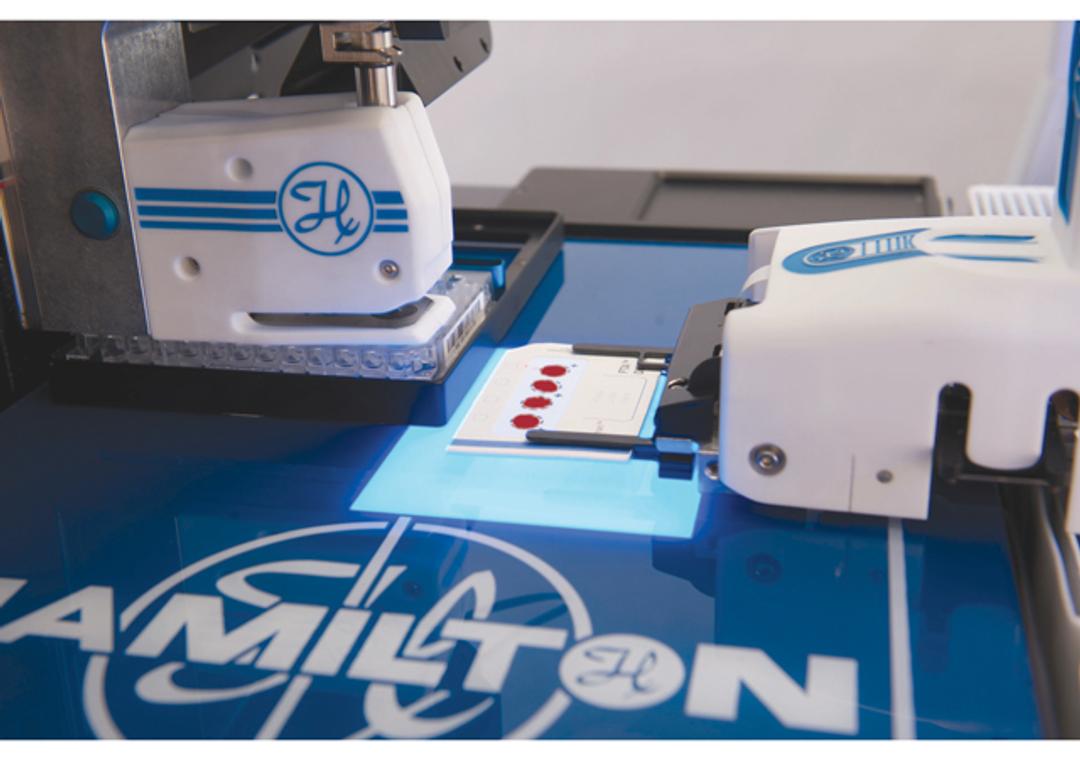

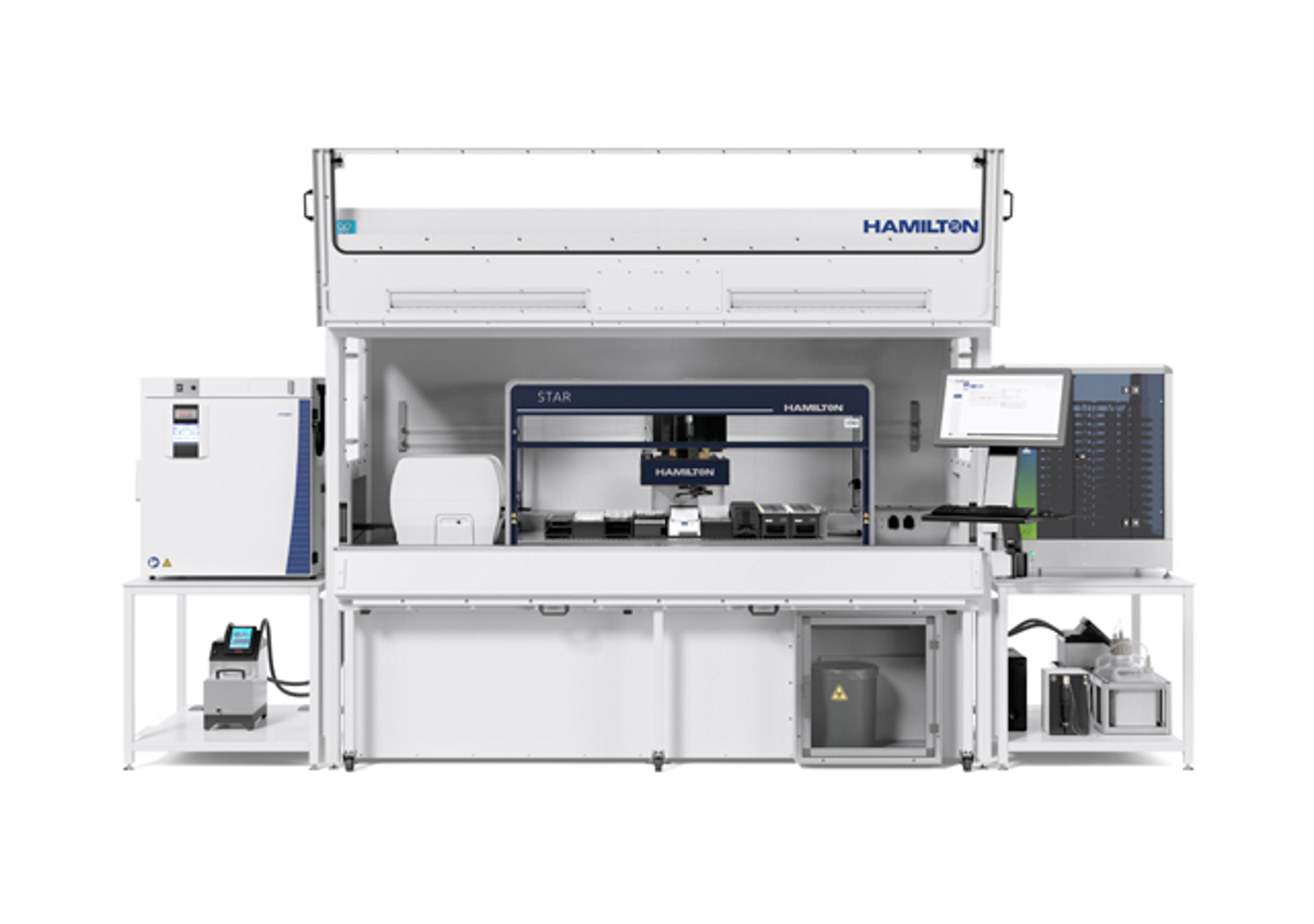

Advanced Sample Collection Card Processing

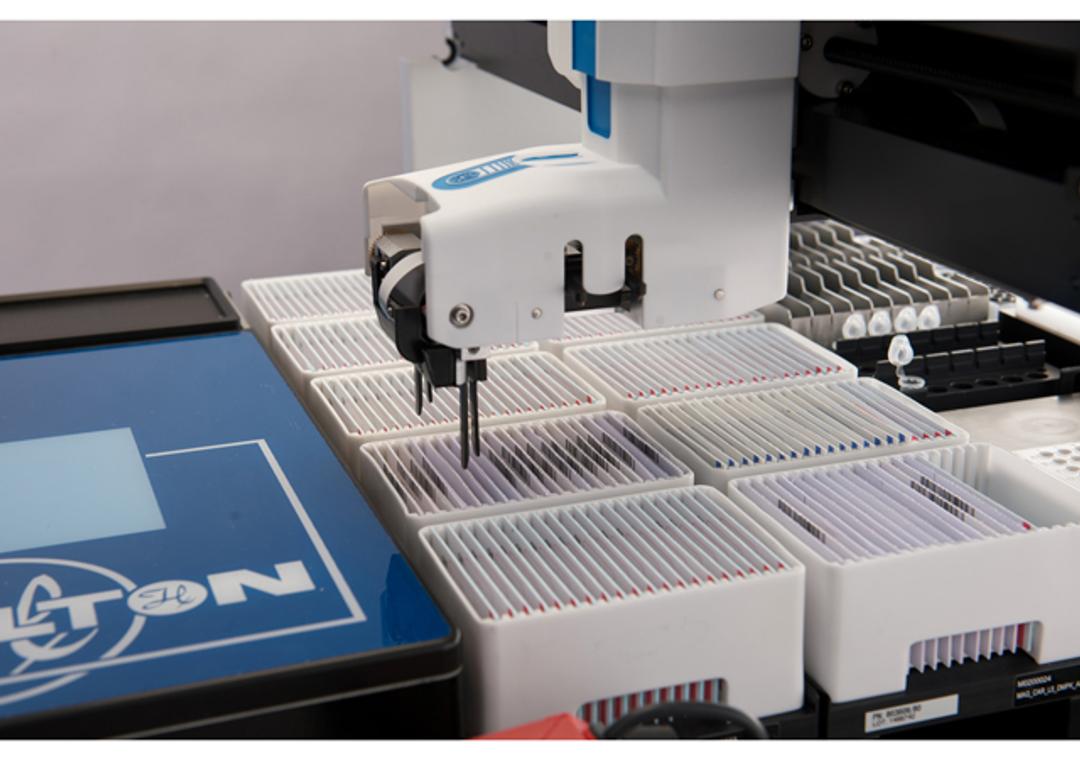

The easyPunch STARlet automates punching and processing of framed sample collection cards (e.g. FTA cards) spotted with blood, plasma, urine, buccal swabs, saliva, and other biofluids. It can also automate additional downstream applications such as nucleic acid extraction. Up to 200 FTA cards may be loaded at once. Each is identified and fully tracked.

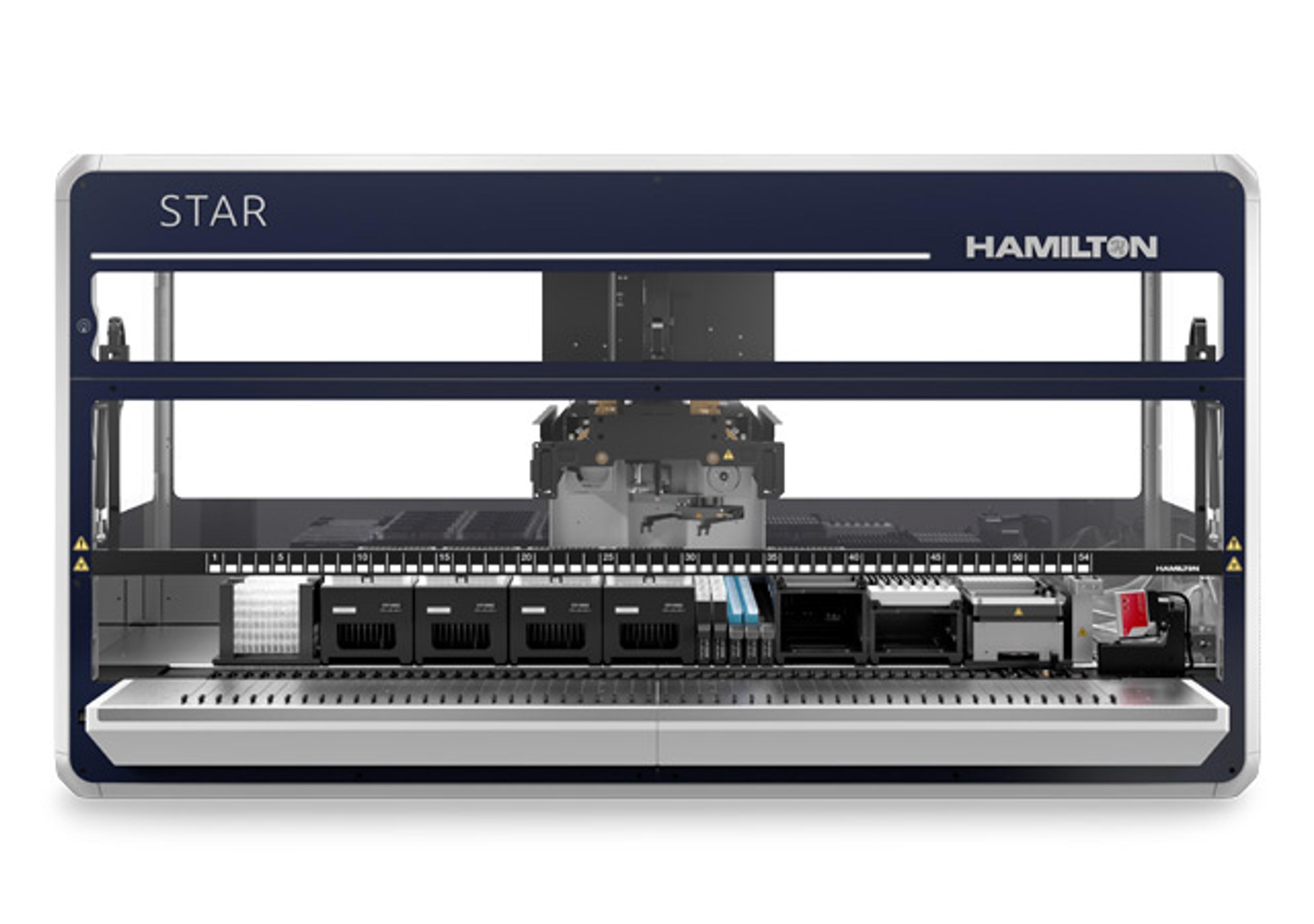

Advanced Image-Based Recognition

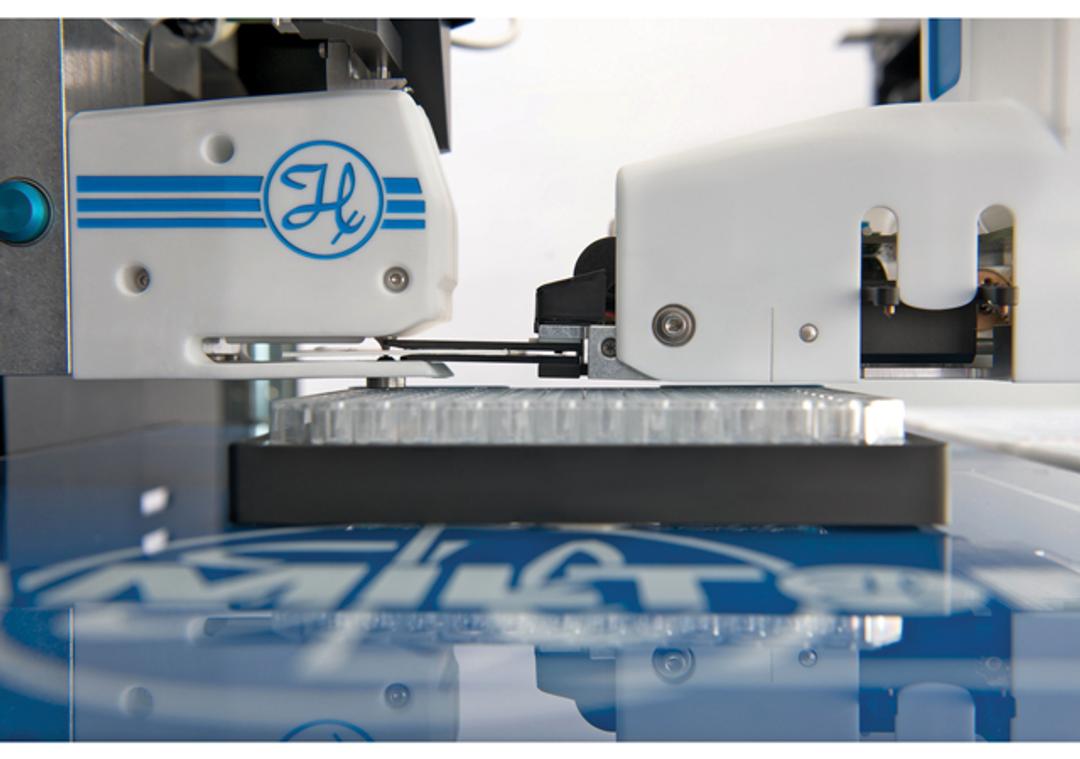

Indicating or non-indicating sample collection cards are imaged on the deck-mounted punch module to determine optimal punch position. The punch strategy also includes recognizing previously punched positions and determining valid cleaning punch locations. Administrators may fine-tune parameters based on the lab’s validation studies.

Four interchangeable punch head sizes are available, and process controls reduce static and dust. Pre- and post-punch images, along with sample tracking data, are stored and sent to a Laboratory Information Management System (LIMS) for inclusion in case files and reports.