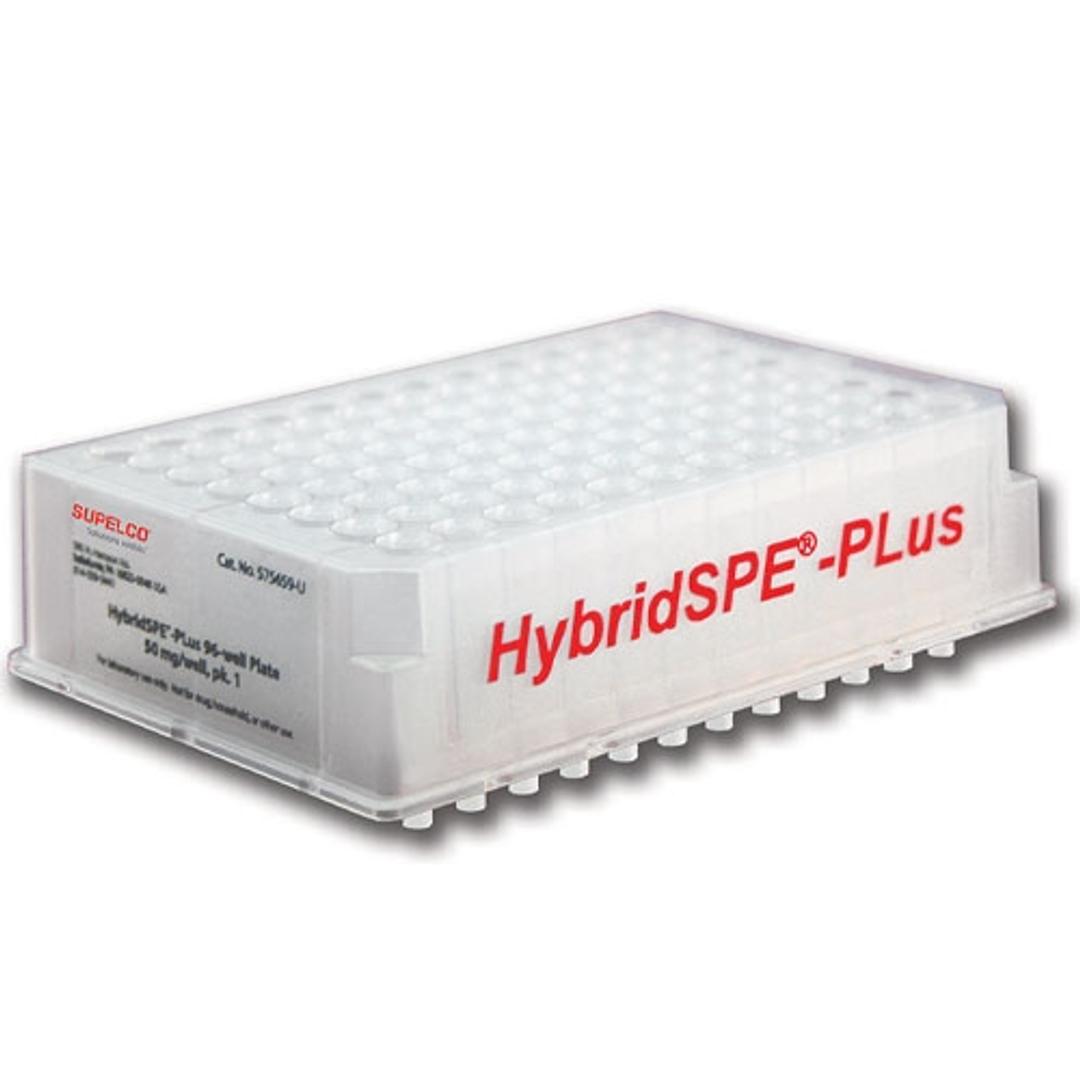

HybridSPE®-Plus Plates

Our HybridSPE ® -PLus plates effectively remove phospholipids and proteins from biological matrices in a simple pass-through method for accurate and reproducible LC-MS analysis. Unlike other phospholipid removal SPE products on the market, the unique retention mechanism of HybridSPE ® allows for separation of even very hydrophobic analytes from phospholipid contaminants.

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

HybridSPE®-Phospholipid (HybridSPE®-PL) technology combines the simplicity of protein precipitation with the selectivity of solid phase extraction (SPE) for the targeted removal of phospholipids in biological plasma/ serum. The technology utilizes a zirconia coated particle, and exhibits selective affinity towards phospholipids while remaining non-selective towards a range of basic, acidic and neutral compounds. The phospholipid retention mechanism is based on a selective Lewis acid-base interaction between the proprietary zirconia ions (functionally bonded to the HybridSPE® stationary phase) and the phosphate moiety present in all phospholipids.

Features and benefits:

- Merges both protein precipitation and SPE

- Offers the simplicity of protein precipitation

- Selectively removes phospholipids via Lewis acid-base interactions

- 2-3 step generic procedure

- Typically >98% removal of phospholipids and precipitated proteins

- Minimal to no method development required: 96-well or individual cartridge format

- Unique chemistry that can effectively separate hydrophobic analytes (such as vitamins) from phospholipids, unlike competitive product chemistries

- Elimination of proteins and phospholipid-induced ion suppression

- Simultaneous removal of proteins and phospholipids

- Simple, standardized methodology, analogous to traditional protein precipitation

- Alternative to complex traditional SPE method development

- Reproducible, consistent performance reduces need for reprocessing

- Less instrument downtime and longer column life

- Decreased run times by eliminating the need for gradients to clean columns between samples

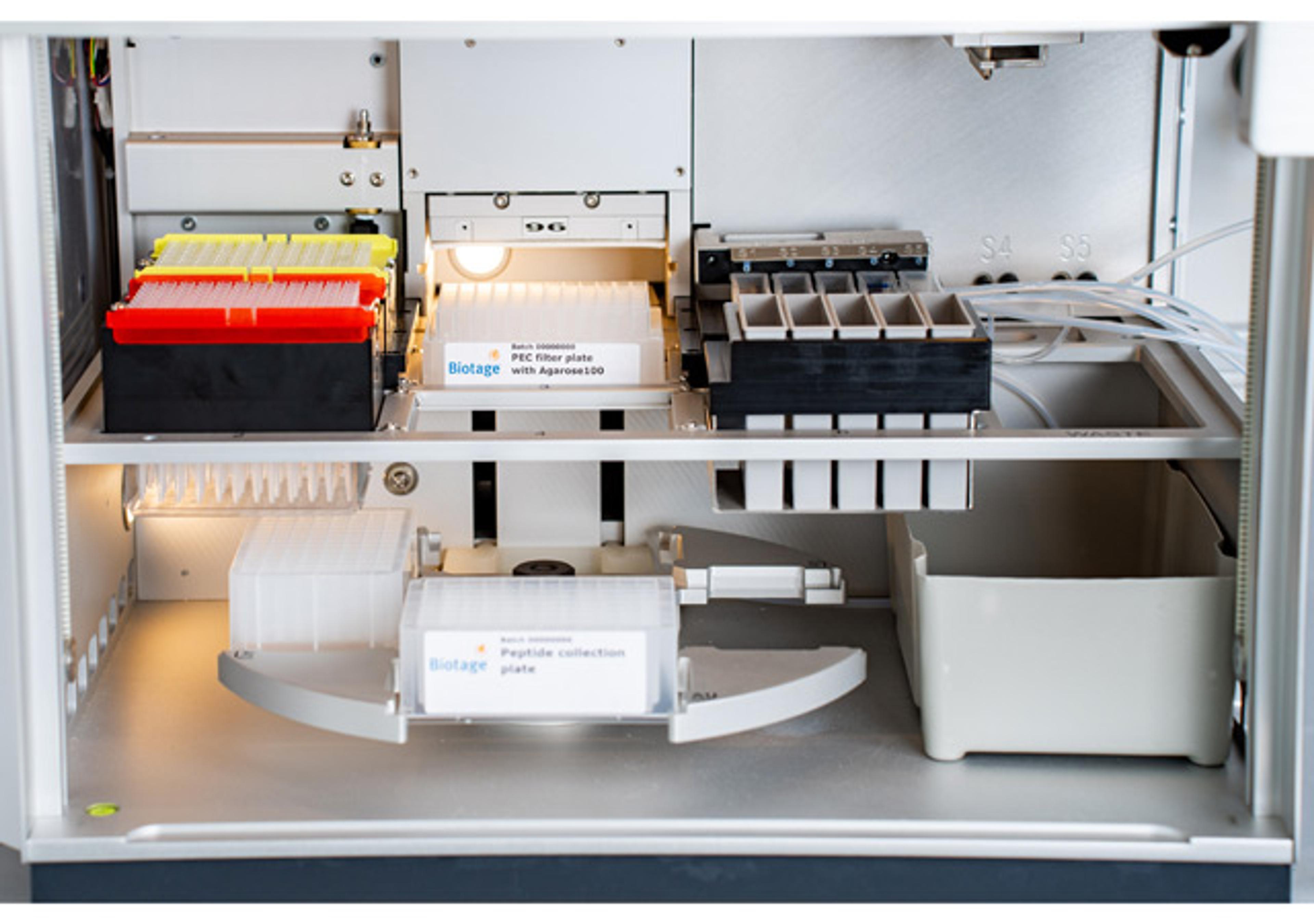

- High throughput processing that is automatable and compatible with common robotic systems

- Ready-to-use, no preconditioning required