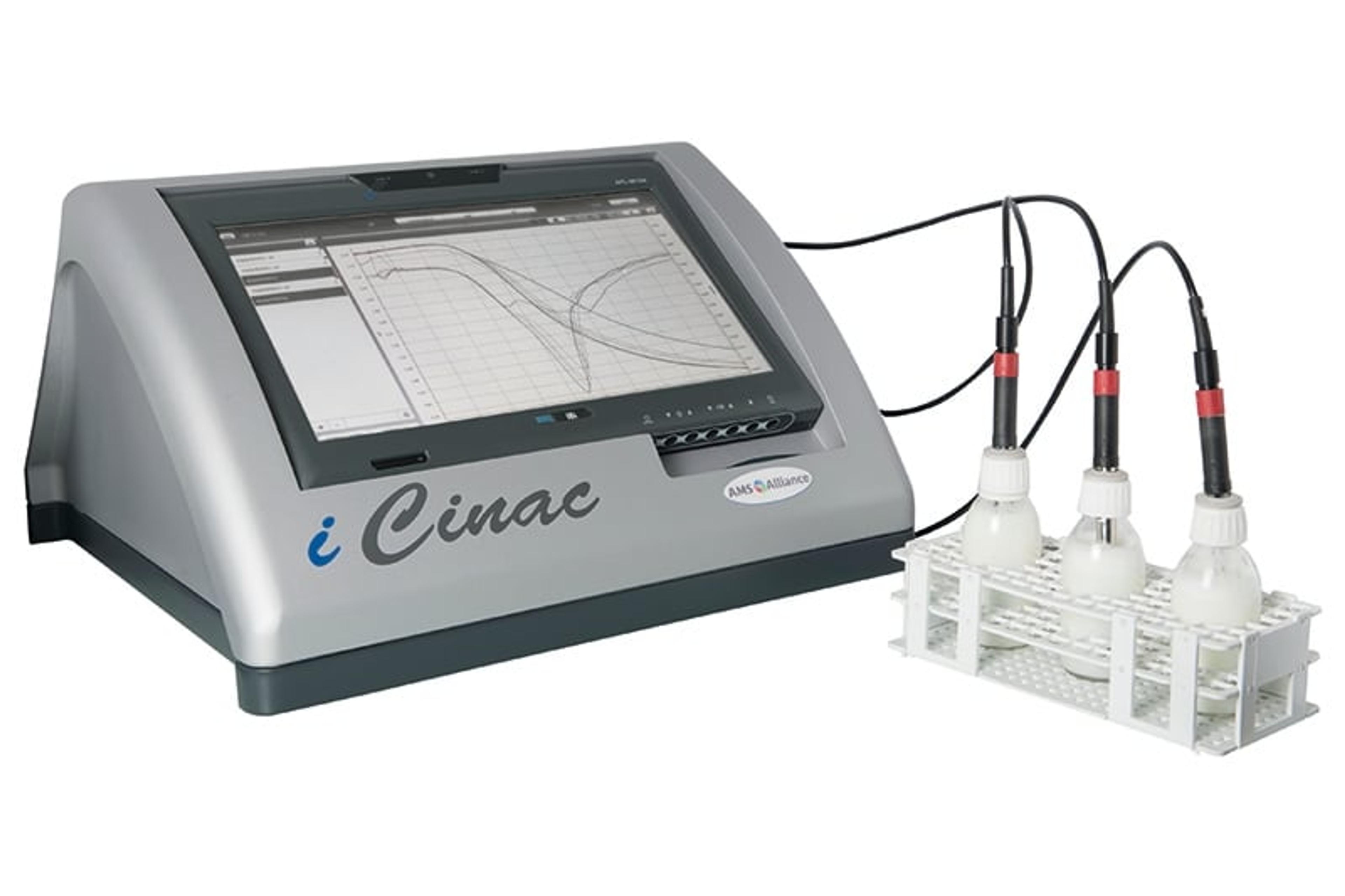

iCinac L.A.B. Fermentation Monitor

The iCinac Fermentation Monitor, wired or wireless, helps monitoring lactic Acid Bacteria (LAB) used as starter cultures in the food industry. Monitoring the behavior of these starters allows ferment and starter culture manufacturers to optimize these difficult processes, ensuring consistent LAB activity and consistent quality of the end product. The iCinac Improves quality control, R&D, product development and process opti…

The iCinac Fermentation Monitor helps monitoring lactic Acid Bacteria (LAB) used as starter cultures in the food industry. Monitoring the behavior of these starters allows ferment and starter culture manufacturers to optimize these difficult processes, ensuring consistent LAB activity and consistent quality of the end product. The iCinac Improves quality control, R&D, product development and process optimization

Features

- Uses ISM® protocol digital probes (pH/Temp, pH/ORP/Temp)

- Scalable – up to 32 channels for wired version, up to 16 for wireless version

- Meets ISO 26323|IDF 213, the industry standard for determining dairy cultures’ acidification activity by continuous pH measurement

Benefits

- select the number of channels, the number of probes, and subsequently add or remove probes from the systems. It can be combined with wireless version.

- Ensures inter-batch kinetics consistency in compliance with ISO standards

- Reduces product development timelines because of the reactor-scale, efficient design and your choice of ferment

Applications

The iCinac Wired is used in many industries, and monitors the acidification activity of ferments and control of LAB fermentation reactors in:

- Dairy

- Fermented foods (LAB)

- Probiotics

- Ferment and bacterial culture production

The iCinac is also a useful tool in R&D, product and process development and quality control to:

- Find the most efficient starter for manufacturing needs

- Check batch consistency of the starter

- Determine the acid forming characteristics specific to the phylum studied

- Provide the insight needed for precise development, test, and process control of fermentation ingredients

- Define and control the appropriate inocula by characterizing the acid formation of a specific phylum and knowing the specific test parameters’ influence