In-VitroCell ES NU-5700 Direct Heat CO2 Incubator

Quality and reliability have been carefully designed and built into the NuAire ES NU-5700, offering the ideal in-vitro environment where optimized tissue cell growth is of the utmost importance. Incredibly reliable and advanced computer technology provides the ability to precisely manage the CO2 gas control system and temperature to achieve the precise requirements for sensitive cell cultures. Constant Contamination Co…

It's a reliable CO2 Incubator.

Cell cultures

The Incubator is easy to run, but the air flow needs to be regulated for the water condensation. Also, we've found some corrosion on the floor, where the water pan is located. The filters are easy to exchange, with the exception of the inner one. We cannot find the service at our region to perform that. It's going to be a very expensive service.

Review Date: 20 Dec 2018 | NuAire, Inc.

Quality and reliability have been carefully designed and built into the NuAire ES NU-5700, offering the ideal in-vitro environment where optimized tissue cell growth is of the utmost importance. Incredibly reliable and advanced computer technology provides the ability to precisely manage the CO2 gas control system and temperature to achieve the precise requirements for sensitive cell cultures.

Constant Contamination Control

Closed Loop HEPA Filtration

Using the rigorous standards of an ISO Class 5 Clean Room's environment, the In-VitroCell™ CO2 incubators have been engineered to keep contamination to a minimum. All gas and air are passed through 99.99% HEPA filters before entering the growth chamber, ensuring a sterile environment. To help prevent cell desiccation, chamber air cycles through one air change at 30-minute intervals. An extremely sensitive sensor bay constantly monitors the chamber environment, making necessary adjustments to maintain consistency.

Coved Interior Corners

Contaminants are quickly eliminated from the interior growth chamber, thanks to the rounded corners and smooth surface.

Technology

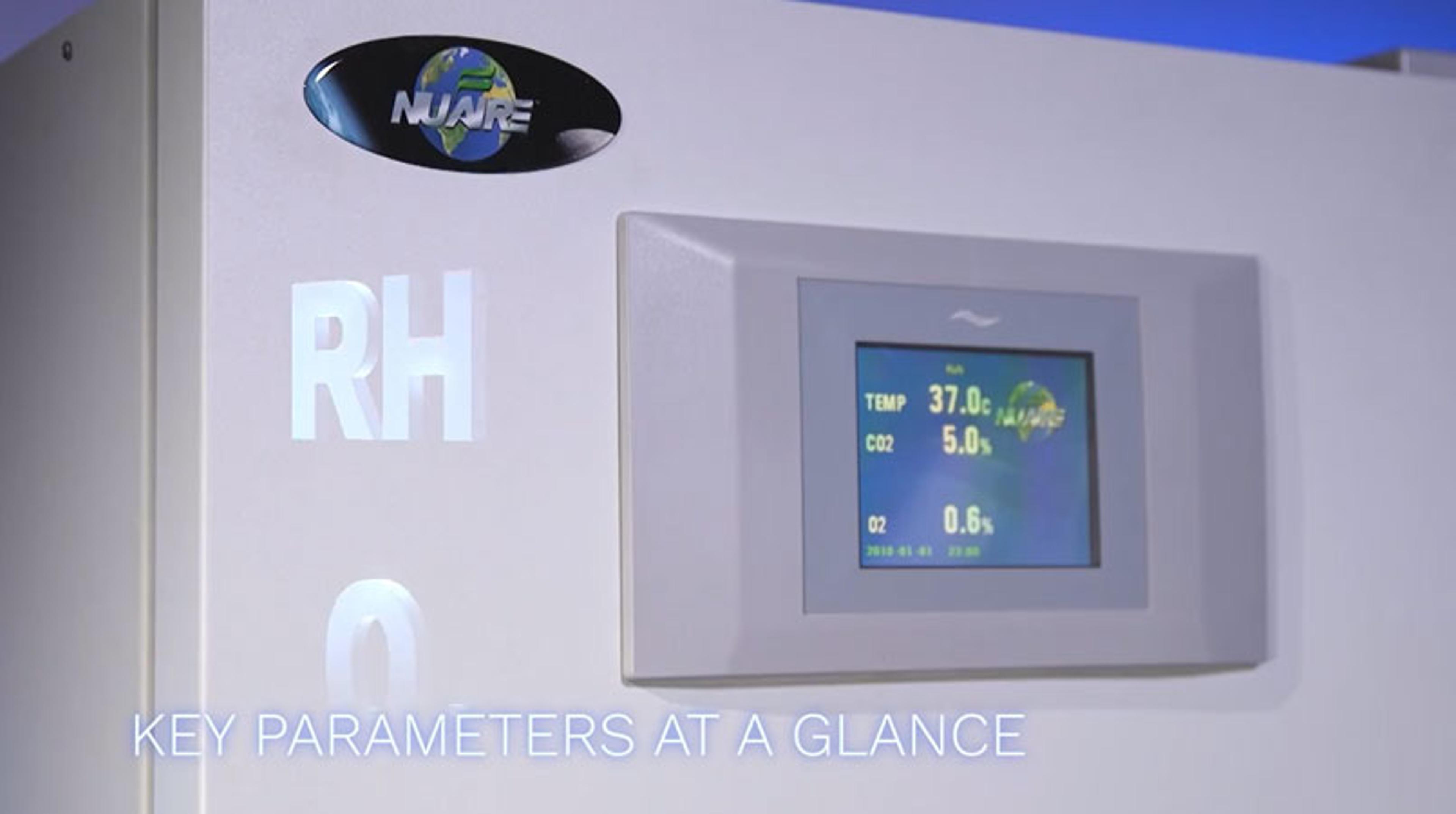

NuTouch (Touchscreen) Electronic Control System (ECS)

Four different languages (English, French, Spanish and German) and a 5x7 inch (127x178 mm), standard on each In-VitroCell incubator allow users to easily view and control the system with the touch of a finger. Quickly access system parameters such as set points and monitor temperature history and carbon dioxide graphs right on the screen (USB download capable). Readily update the chamber environment with preset service settings. Continuously monitor system status on the color screen while the incubator is in standby mode, making chamber adjustments or sampling air.

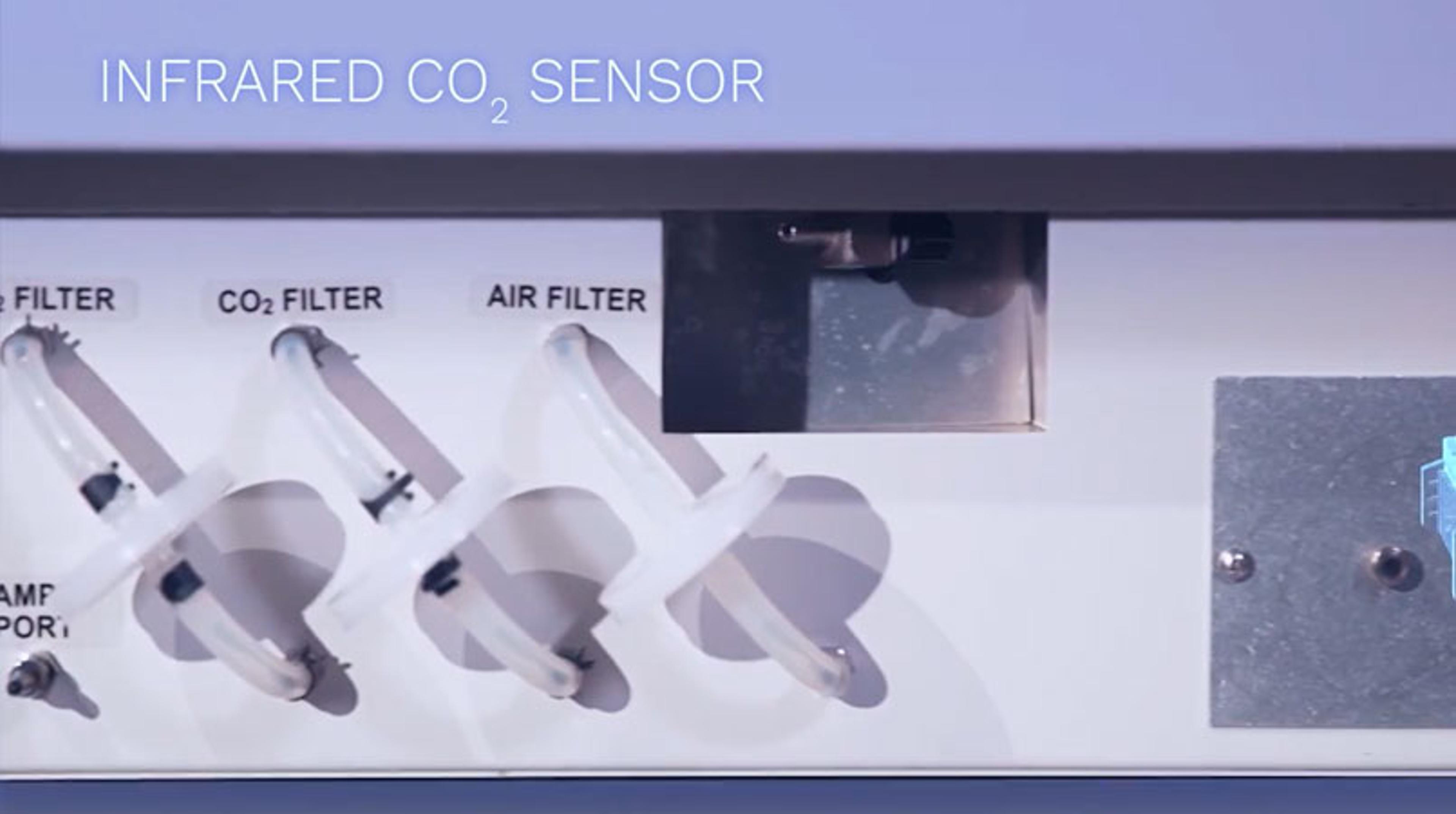

Sensitivity and Accuracy of Gas Control

A highly selective single source dual wave infrared (IR) sensor allows for incredibly sensitive and accurate CO2 control (within ±0.1%). Located in the sensor bay, this microprocessor-based IR sensor's wavelengths are specifically absorbed by CO2, making it impervious to input from other elements such as water vapor, allowing for a highly stable output and minimizing the need for frequent calibrations.

Performance

Temperature Uniformity

Optimum uniformity is achieved through the use of R5 insulation-wrapped foil heating elements surrounding a 5.7 cubic foot growth chamber. Specially designed dual temperature sensor probes continuously monitor and send information to the NuTouch ECS, making any needed adjustments. Temperature uniformity is maintained throughout the chamber with accuracy to within ±0.3°C.

Heat Recovery

Quick heat recovery at 0.12°C per minute allows a rapid return to set point temperature.

Humidity Control

Through the use of a stainless steel pan filled with distilled water (must not be purer than 1 mega-ohm) and placed on the chamber bottom, a relative humidity of up to 90% can be achieved and maintained.