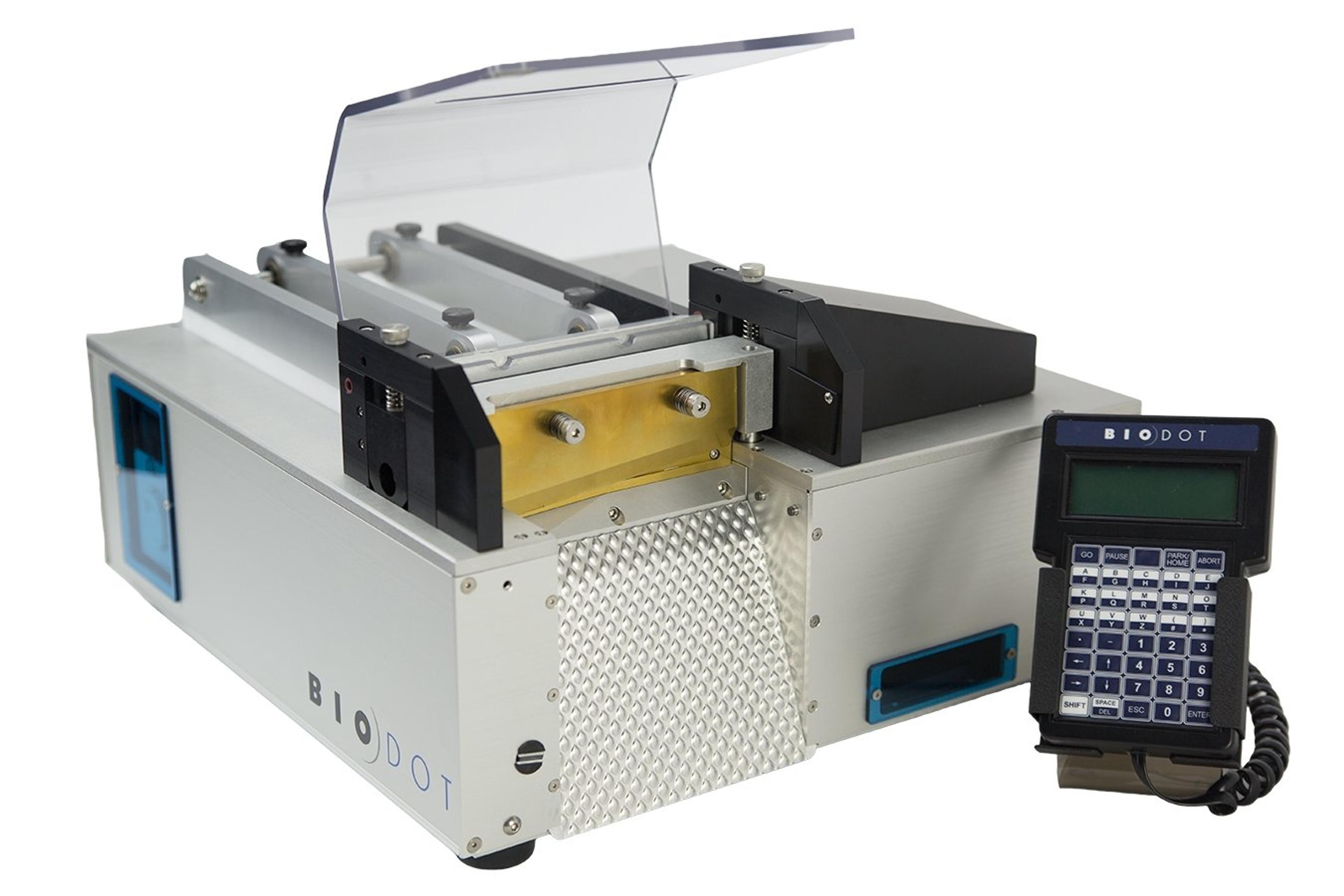

LM9000 Continuous Laminator

The Automated Laminating system is a modular design to accommodate various numbers and types of materials. Each material is fed from adjustable spindles through guides and under a pressure roller to assure complete adhesion to the plastic support backing. The system provides the ability to individually remove kiss cut adhesive liners for individual laminate materials. For fragile materials like nitrocellulose, alignment is con…

The Automated Laminating system is a modular design to accommodate various numbers and types of materials.

Each material is fed from adjustable spindles through guides and under a pressure roller to assure complete adhesion to the plastic support backing. The system provides the ability to individually remove kiss cut adhesive liners for individual laminate materials. For fragile materials like nitrocellulose, alignment is controlled through automated tracking. After lamination the materials can either be cut and stacked in a collection chute or rewound onto a take-up reel. Other process steps such as dispensing, slitting, punching and inspection can also be integrated into the system.

For materials that are not available or cannot be processed in roll formats, a magazine feeding system has been designed. Magazines for feeding the plastic support backing as well as more fragile materials are available. The system can also be partially or completely enclosed for control of the manufacturing environment.