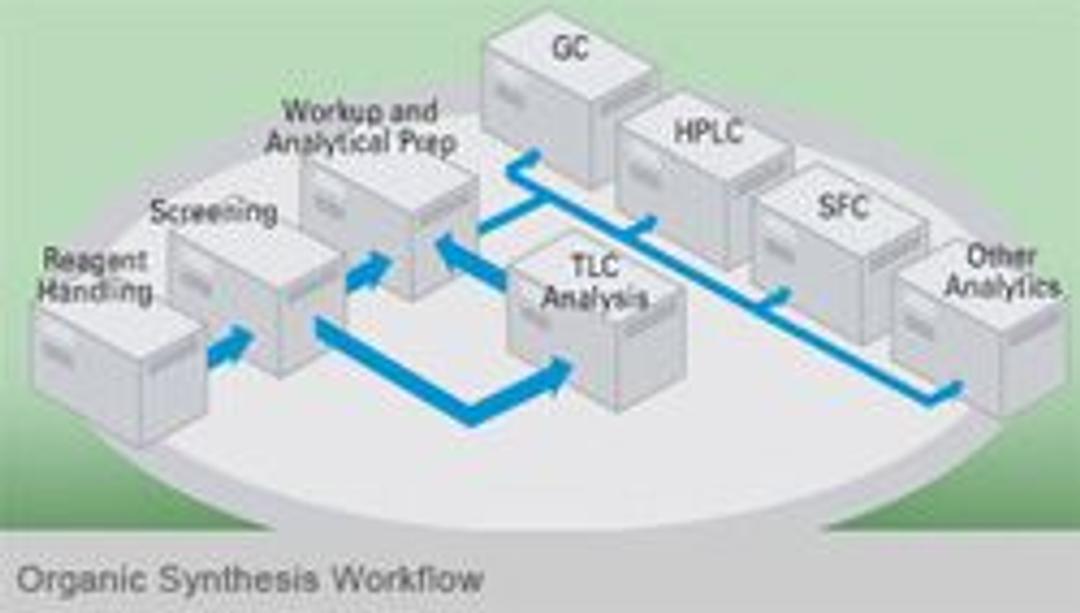

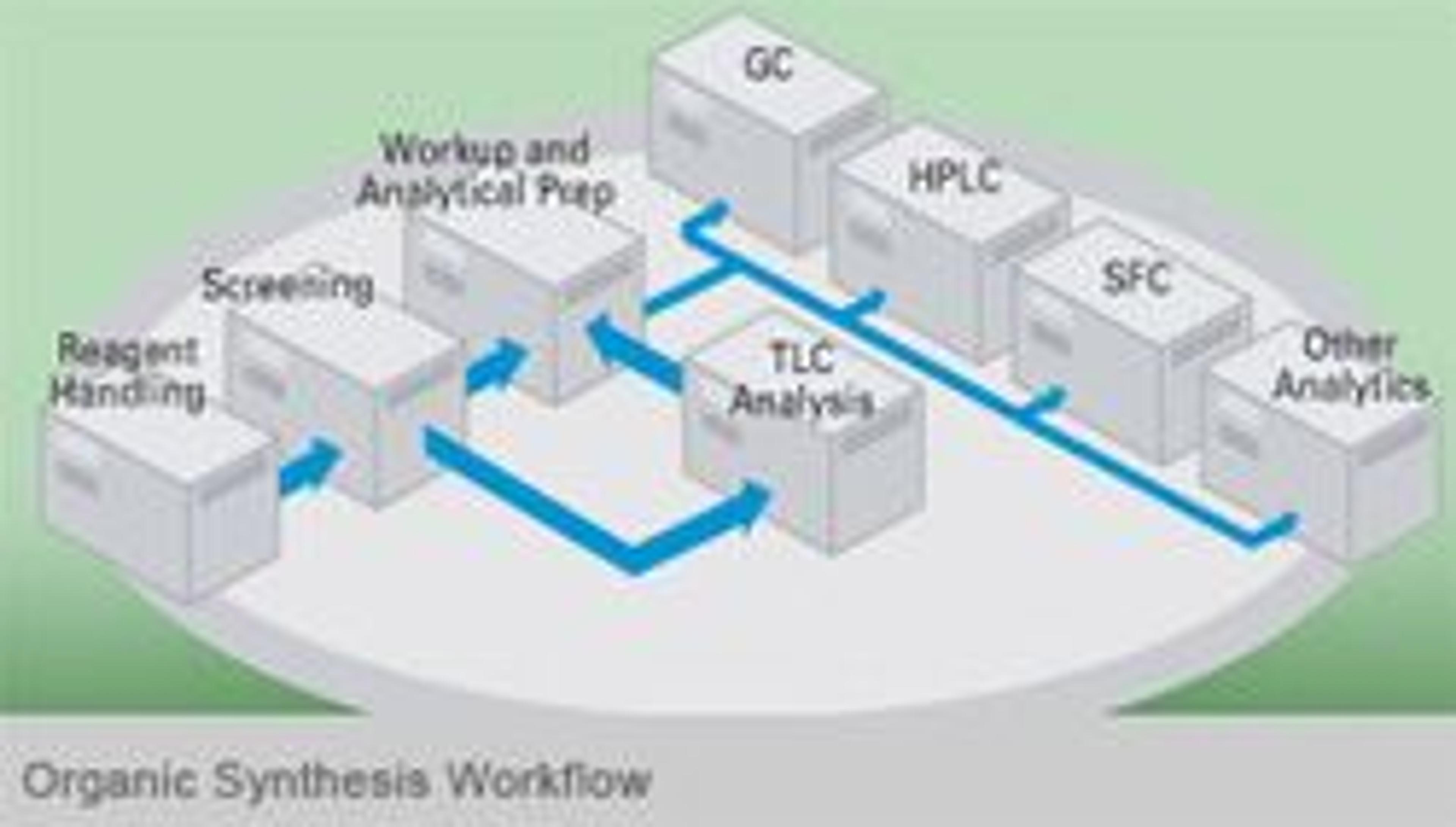

Organic Synthesis Workflow

Consistently design, synthesize, screen, and analyze reactions using this automated, high-throughput workflow. Significantly increase the number of high quality experiments per year while decreasing experimentation time and manufacturing costs. The Organic Synthesis Workflow utilizes a parallel batch reactor (PBR) to screen hundreds of reactions per day under different stoichiometries, reaction concentrations, and temperature…

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Consistently design, synthesize, screen, and analyze reactions using this automated, high-throughput workflow.

Significantly increase the number of high quality experiments per year while decreasing experimentation time and manufacturing costs.

The Organic Synthesis Workflow utilizes a parallel batch reactor (PBR) to screen hundreds of reactions per day under different stoichiometries, reaction concentrations, and temperature conditions. Rapidly analyze reaction products with a wide range of analytic techniques.

Prepare: Broaden the scope of experimentation without increasing time

- Easily design experiments to explore a diverse set of reaction conditions in a much shorter time than by traditional methods.

- Define gradients of catalysts, reagents, solvents, etc.

- Screen substrates, catalysts, reactants, solvents, and reaction conditions (time, temperature, stoichiometry, concentration) for a wide range of condensed phase reactions.

Process: Screen more reactions accurately, and with minimal reagents

- Accurately dispense small amounts of reagent solutions or slurries minimizing consumption of precious materials.

- Screen hundreds of reaction conditions per day under a range of temperature and pressure conditions to quickly define and optimize process parameters.

Analyze: Quickly analyze and visualize data to further define experimentation

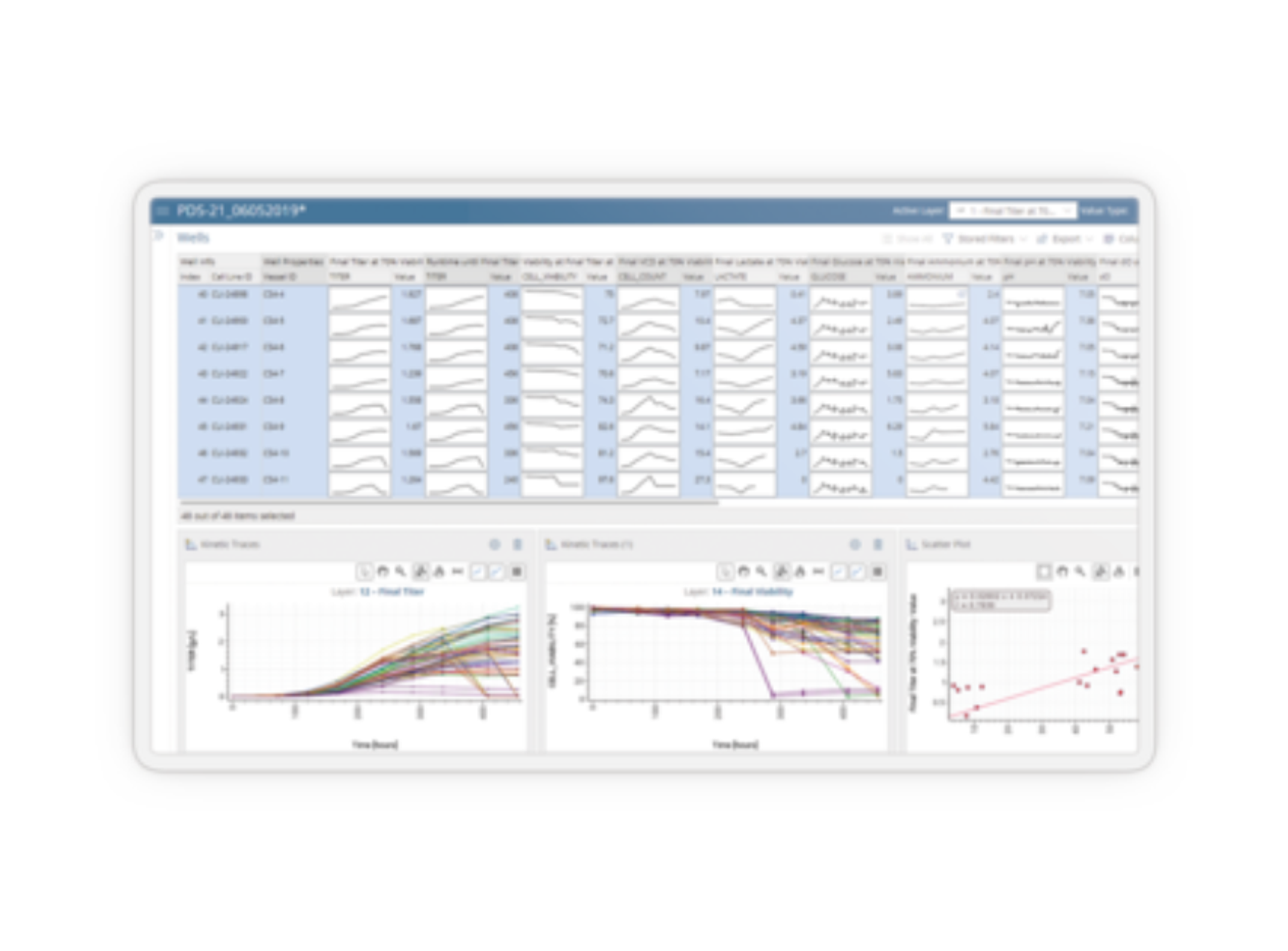

- Create, calculate, and visualize data using Symyx Software.

- Generate process knowledge for further optimization and definition of process parameters.