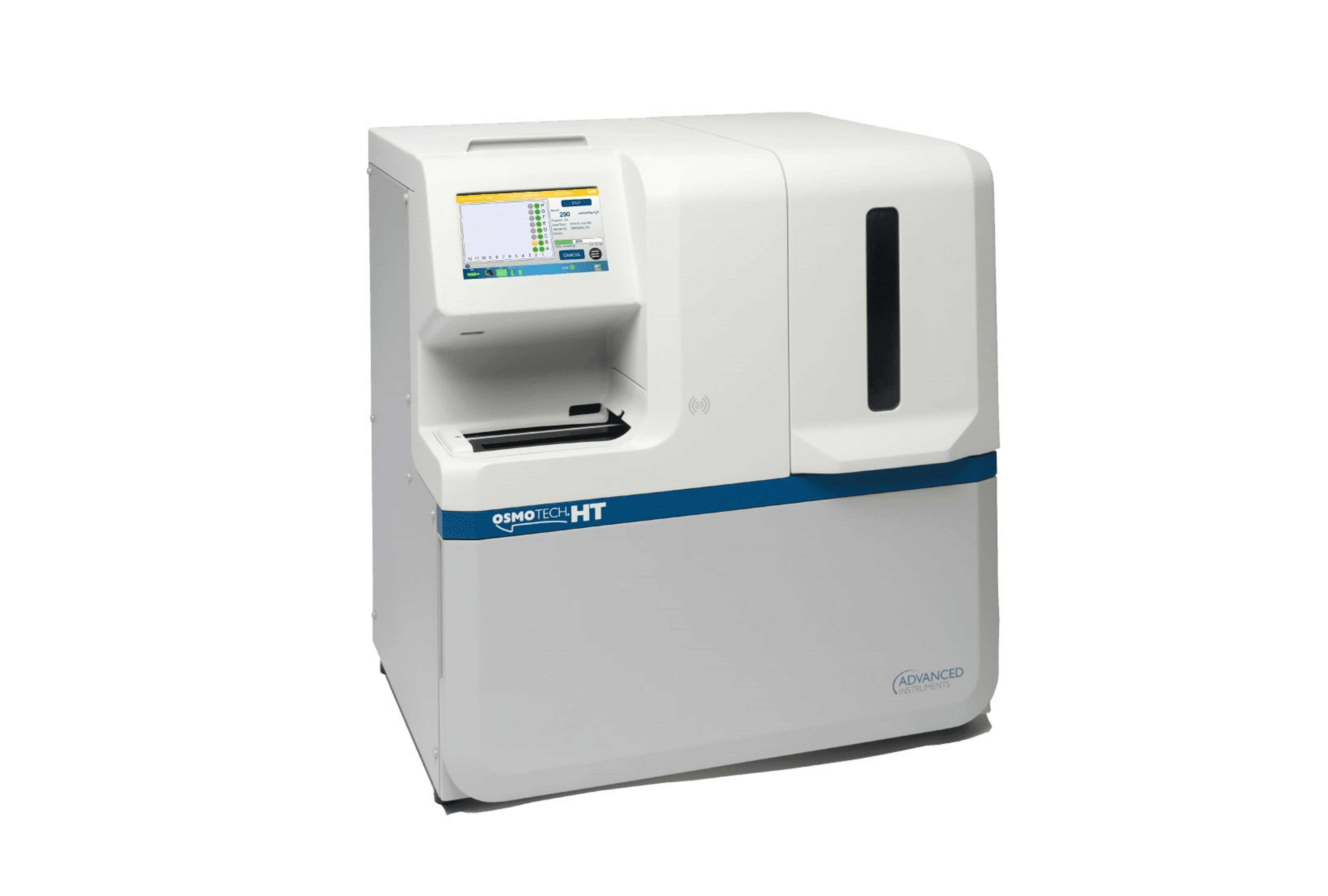

OsmoTECH HT Automated Micro-Osmometer

The only plate-based osmometer for high-throughput bioprocessing labs

Easy to use, reliable, and increases walk-away time!

Analyzing osmolality of samples

Equipment was easy to set up and easy to use. It runs reliably and is great to have for running many samples.

Review Date: 29 Mar 2022 | Advanced Instruments

The OsmoTECH HT is the only plate-based micro-osmometer currently available to support the growing automation and high throughput needs in bioprocessing. Designed in a 96 well format this automation-friendly instrument ensures efficiency and acceleration of osmolality testing in early process development, formulation development and quality control workflows. The OsmoTECH HT provides intuitive workflows and delivers unsurpassed data management and connectivity supporting 21 CFR Part 11 compliance features for GMP workflows.

Features

- Effortlessly Run Multiple Samples - The plate-loading format allows samples to be robotically pipetted into the 96-well plate. Load up to two plates onto the device for 192 tests.

- Automate duplicate and triplicate testing – The instrument is designed to pipette duplicate and triplicate samples from the same well allowing for increasing confidence in results and not disrupting the user workflow.

- Test up to 1000 samples no customer intervention

- Automation-Friendly Workflows -Streamline efficiency and reduce hands-on operator time with seamless integration with automation workflows and liquid handling automation systems

- User-Friendly Interface - intuitive operating system and touchscreen interface provides a step-by-step guide to tests and allow users to easily get the status of tests and consumables.

- Small Sample Size - Just a 40µL sample volume is needed for testing

Flexible and Secure Data Management - Quickly save data to a network database, USB device or web server. Automate the sample identification process and instrument control with bi-directional communication to eliminate transcription errors and save time. - 21 CFR Part 11 features - Data integrity features support 21 CFR part 11 compliance for ease of implementation into a GMP environment.

- Automated Self-Cleaning - Eliminate sample carryover and cross-contamination with automated sampling and fluid cleaning.