Parallel Dynamic Mechanical Thermal Analyzer (Parallel DMTA)

A complete foundation for faster, automated workflows in the chemicals and pharmaceuticals laboratory The measurement of the modulus of polymer samples as a function of frequency, temperature, or time is critical to the evaluation of new materials. As methods and apparatus become available for the rapid synthesis and formulation of these materials, at rates of up to 1,000 per day, the evaluation of their properties becomes the…

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

A complete foundation for faster, automated workflows in the chemicals and pharmaceuticals laboratory

The measurement of the modulus of polymer samples as a function of frequency, temperature, or time is critical to the evaluation of new materials. As methods and apparatus become available for the rapid synthesis and formulation of these materials, at rates of up to 1,000 per day, the evaluation of their properties becomes the rate limiting factor.

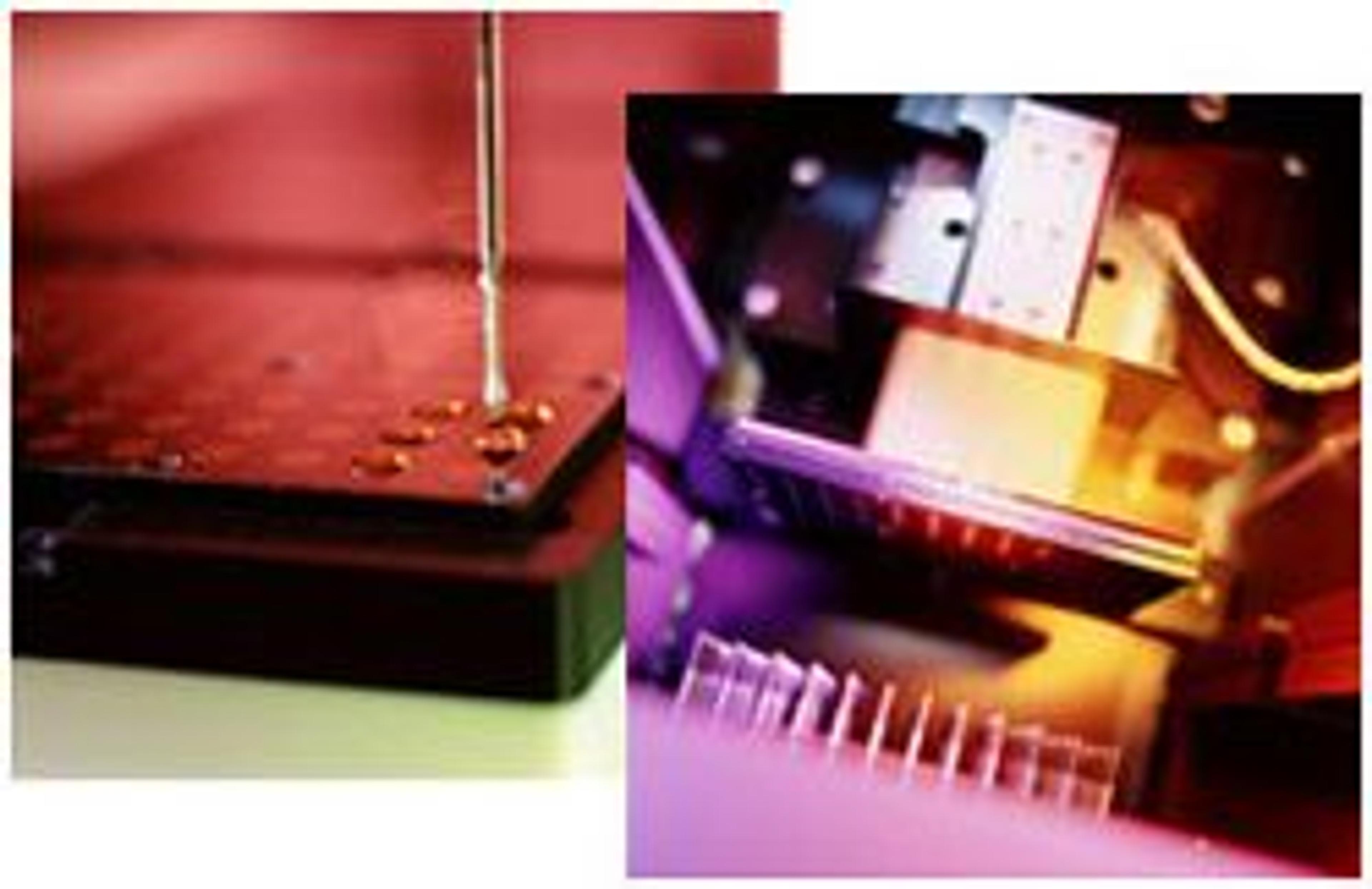

The Parallel DMTA (pDMTA) workflow is designed for high-throughput, bottleneck-free sample preparation and modulus measurement of polymer sample arrays.

Prepare: Plans and execute large combinatorial experiments

- Arrays of samples can be prepared as films cast from solutions or melt-pressed onto the test substrate.

- Multiple deposition methods allow for flexibility in sample form, eliminating the requirement for materials to be soluble.

Process: Perform more high quality, validated experiments

- Film thickness can be characterized using either a contact or non-contact approach.

- Arrays of samples undergo identical pre-measurement environmental conditions, reducing possibility of errors due to variations in sample treatment.

Analyze: Increases development success through breadth of experiments

- 96 simultaneous measurements of modulus as a function of temperature, frequency or time provide a rich pool of information in the same amount of time as a single measurement on a standard DMTA.

- Well matched to throughput of synthesis and formulation techniques, removing bottleneck at the characterization step.

- Provides capabilities to obtain statistical data in a single experiment, improving data reliability.