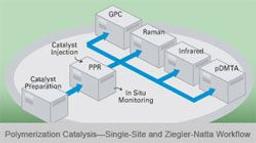

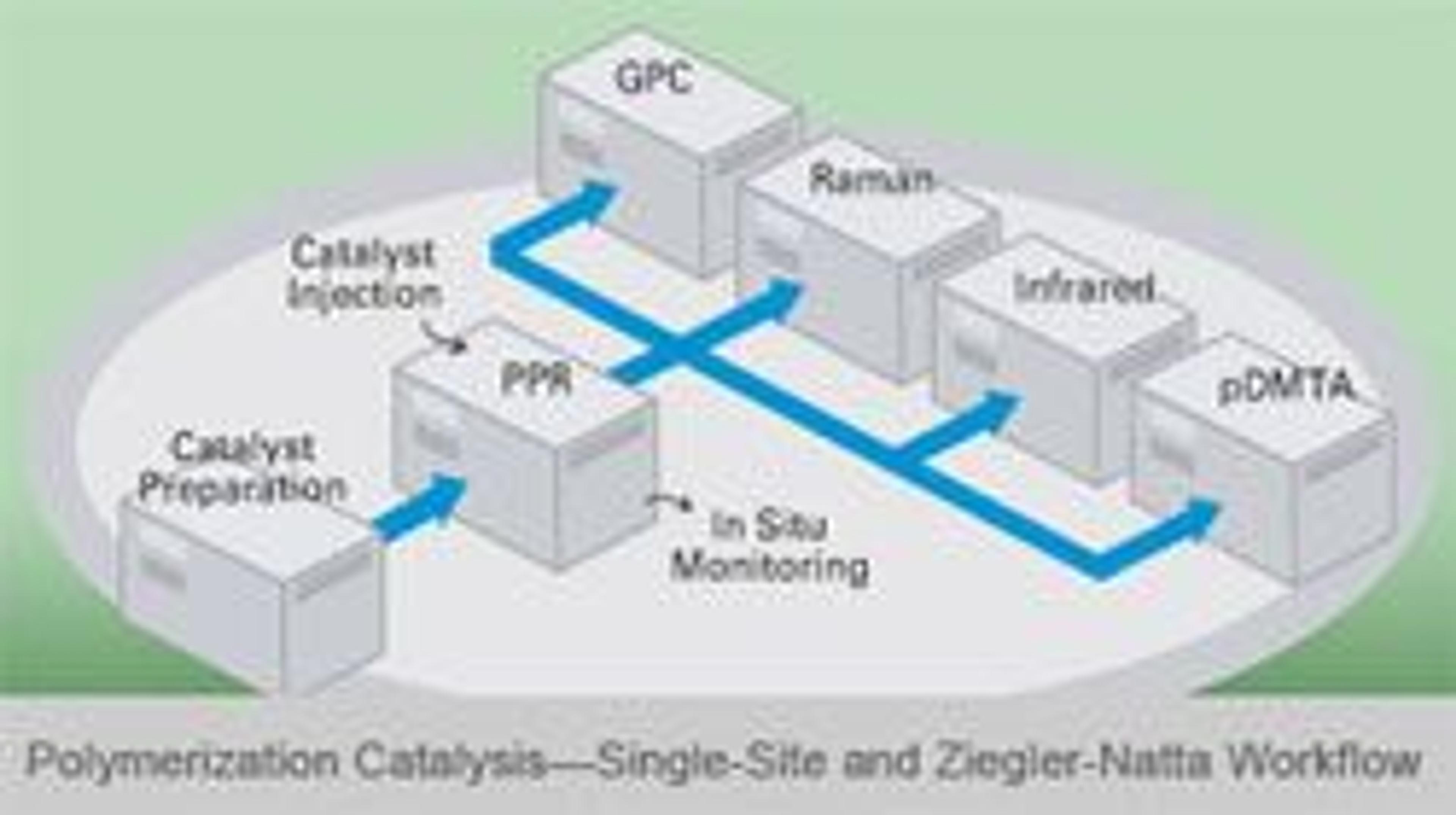

Polymerization Catalysis Workflow

Perform 48–96 meaningful slurry or solution phase (co)polymerizations per day and increase the productive value of research and development by enabling better decisions, faster. Through the integration of reactor hardware, robotics, and custom software capabilities, the Polyolefins Workflow facilitates 48–96 slurry or solution-phase batch reactor polymerizations with full computer control and in situ temperature and pressure m…

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Perform 48–96 meaningful slurry or solution phase (co)polymerizations per day and increase the productive value of research and development by enabling better decisions, faster.

Through the integration of reactor hardware, robotics, and custom software capabilities, the Polyolefins Workflow facilitates 48–96 slurry or solution-phase batch reactor polymerizations with full computer control and in situ temperature and pressure monitoring capability for each reactor cell.

Prepare: Rapidly screen catalyst formulations and associated polymer products across multiple research fields

- Perform Supported and Solution Phase Polymerizations with tailored catalyst preparation workflows and PPR hardware.

- Fully validated workflows address silica-supported single-site, MgCl2-supported Ziegler-Natta, silica-supported chromium, and solution-phase catalysts.

- Condensable gas injection enables bulk liquid propylene operation.

Process: Complete meaningful, reproducible experiments, faster

- Real time in situ monitoring capabilities for pressure, temperature, and monomer uptake rate facilitates controlled polymerization conditions and meaningful polymer products.

- Correlations to larger scales established across multiple areas.

- Broad suite of polymer characterization techniques designed to match PPR throughput and polymer yields.

- Characterize polymer products for molecular weight, polydispersity, composition, melting temperature, glass transition temperature, crystallinity, thermal and mechanical properties.

Analyze: Share data across systems and labs

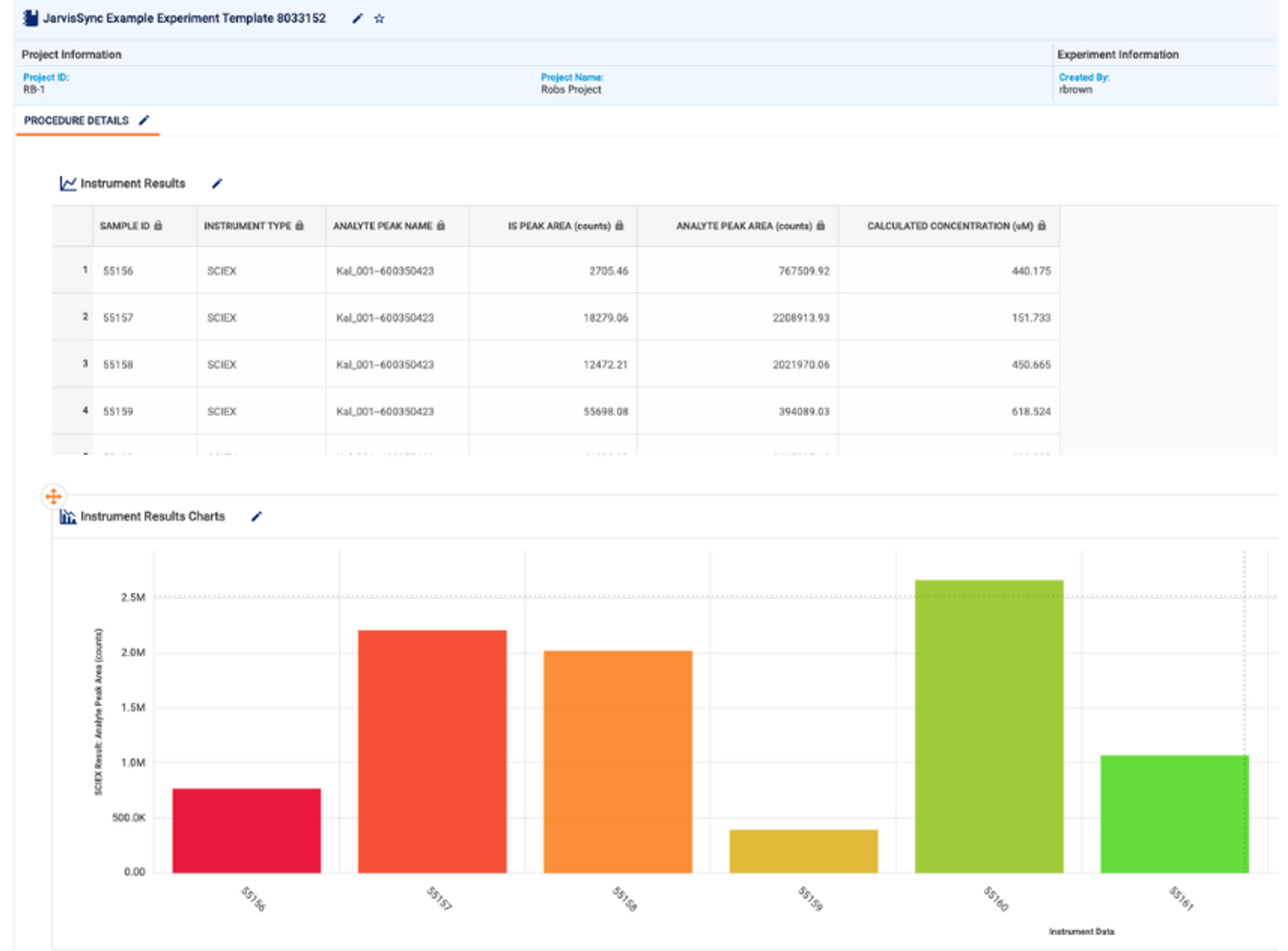

- Create a complete experimental record including library design, reactor set-up, operational parameters, reaction kinetics, product yields, chromatograms, spectra and all associated characterization data.

- Store, retrieve, and search all data on the applications server with Symyx Software to share experimental data across internal and external labs.