Quadra 3®

Full Walk-Away Automation • Infeed Lidded Plate • Interchangeable Pipettors • Reformat Plates 24-96-384-1536 • Ultrasonic Tip Washing • Six Workstations Process up to 100 Microplates Automatically through Complex Protocols • 100 Plate Walk-Away Automation • Filtration Plate Automation • Magnetic Bead Automation • Heat & Cool Plate Nests • Shaking Plate Nests • Windows® Programming A Different Design for each Specific Applicati…

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Transfer supernatant liquid

This is very easy to use product, mainly used to transfer the supernatant from the extracted samples and to do the transfer or loading samples on SPE. Its 96 tip capacity makes it more easy and preferred to use compared to the manual transfer and also there is less chances of error.

Review Date: 20 Nov 2014 | Tomtec Inc.

very helpful.

Review Date: 18 Apr 2011 | Tomtec Inc.

Full Walk-Away Automation

• Infeed Lidded Plate

• Interchangeable Pipettors

• Reformat Plates 24-96-384-1536

• Ultrasonic Tip Washing

• Six Workstations

Process up to 100 Microplates Automatically through Complex Protocols

• 100 Plate Walk-Away Automation

• Filtration Plate Automation

• Magnetic Bead Automation

• Heat & Cool Plate Nests

• Shaking Plate Nests

• Windows® Programming

A Different Design for each Specific Application

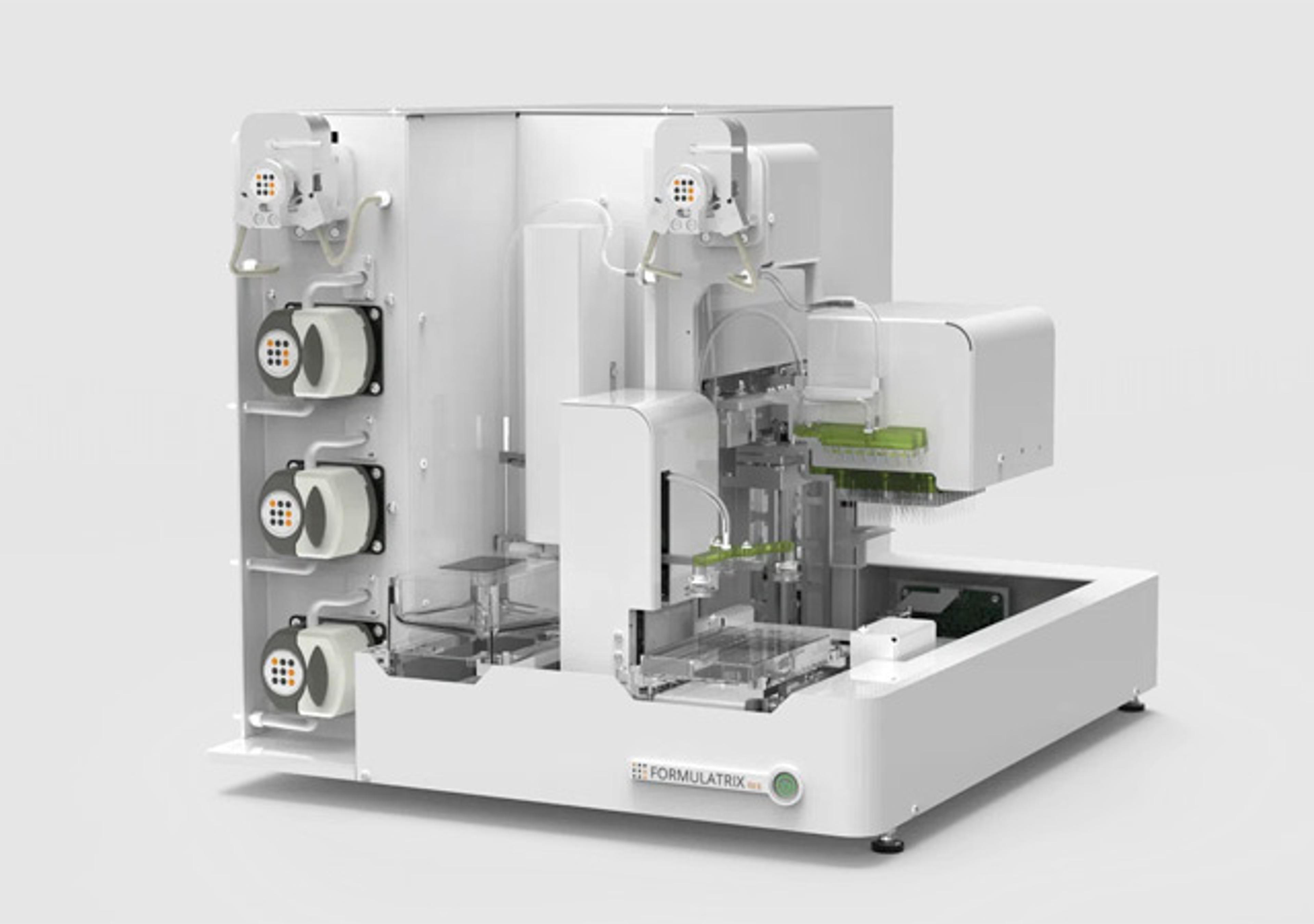

Tomtec's Quadra 3® is a different design concept for liquid handling than our competitors. The primary concept is to do more in less benchtop space. While a large flat bed pipettor has several stations, how do the microplates to be processed infeed and outfeed - manually?

Operational Flexibility

The pipettor is serviced by a 6-station shuttle which carries resources to the pipettor for processing. The shuttle is served by four (4) cassette stackers. Each cassette stacker holds twenty-five (25) microplates, that can be twinned to handle fifty (50). The cassette stackers are interchangeable between other Tomtec products (i.e. plate washer, incubator, plate reading, plate sealing, etc.). Microplates no longer have to be handled individually. They can be moved efficiently through the entire processing protocol by use of cassette stackers. The stackers are pneumatically operated to provide the force necessary for reliable operation. They have the ability to re-stack which means they can also sort. In addition to all types of microplates, the stackers can also place specific reservoirs on the shuttle as the program requires.

The stage automatically lifts plates and reservoirs from the shuttle to the pipettor. The height is precisely controlled to facilitate touching off sub-microliter aliquots. The stage is also used to load tips safely, for both personnel and equipment. The stage cannot get to full force until the tips are in safe contact with the pipettor head, otherwise it is limited to about 10 pounds of force. A full indexing stage is available to reformat from 96 to 384 to 1536 or any other matrix. When used with a single row of tips it can complete serial dilution testing in either the 8 or 12 direction or both, for synergy studies.

Enhance with Specific Application Accessories

The value of the Quadra 3® product line is augmented with application specific accessories that are program controlled. Custom made reservoirs provide less than full plate pipetting. They are used to add Standards & Controls to the plate matrix. Serpentine reservoirs minimize dead volume. Circulated reservoirs provide continuous operation. A special live bottom reservoir is designed to keep particulate matter in suspension (i.e. magnetic beads), various vacuum boxes are available, including a fully automated version to meet the requirements of various filtration protocols. Shaking nests and temperature- controlled nests are also available.