Rapid Extraction System (RES)

The CambTEK Rapid Extraction System – A new approach to automated sample preparation of solid dosage forms for improved quality of data and productivity. CambTEK's Rapid Extraction System (RES) delivers a step-change in performance compared with the existing methods, and is achieved using robust technologies and an intelligent consumable. Utilizing non-invasive turbulent flow with the option of ultasonics the RES delivers many…

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Faster prep, less manual work, and results that consistently hit spec and even matched the internal trend targets.

Pharmaceuticals Sample preparations

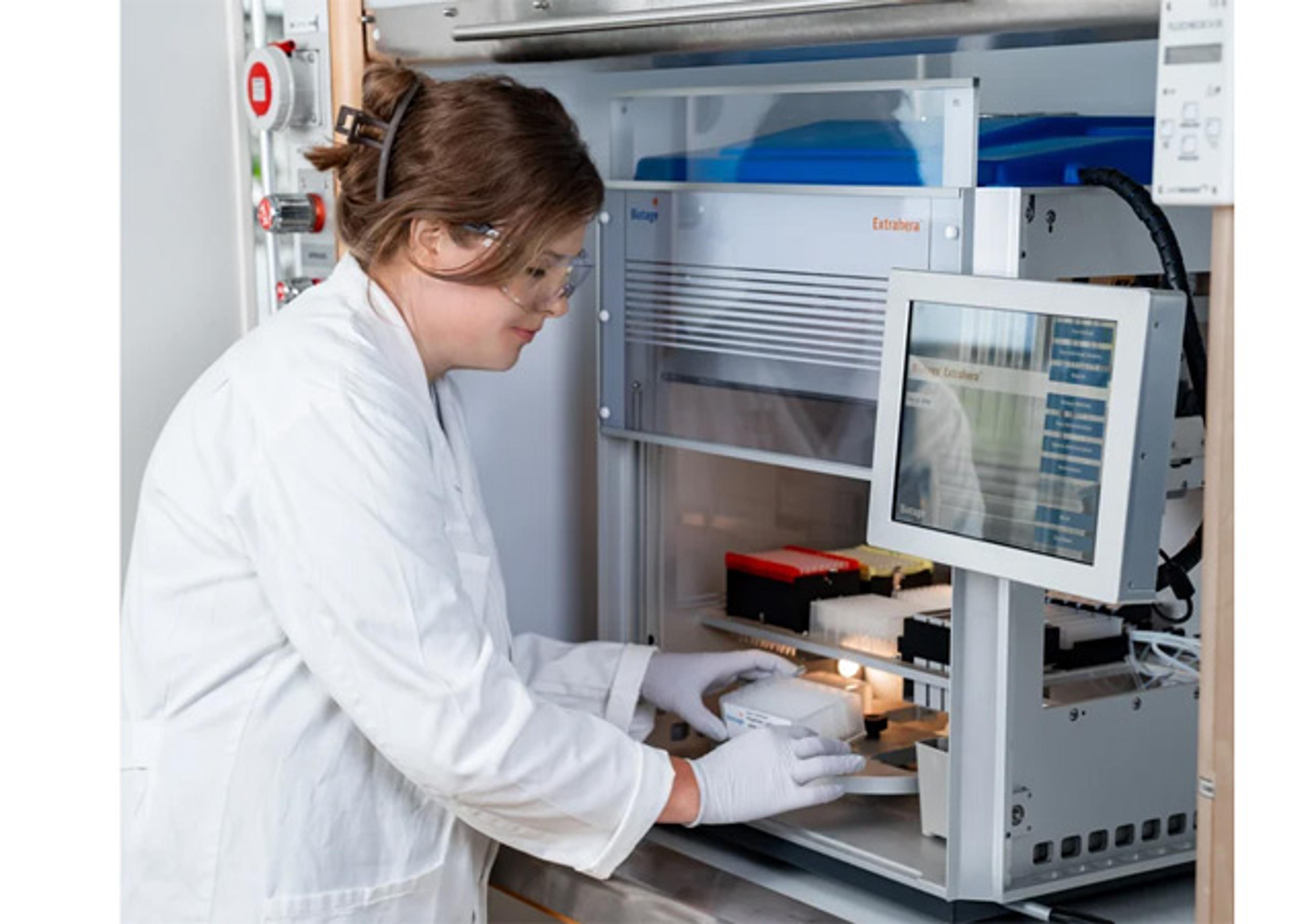

After two intensive months working with Cambtek’s **RES system**, I’ve successfully translated complex manual sample preparation methods into streamlined, automated workflows. The transition wasn’t always simple — aligning the robot’s capabilities with real-world lab challenges required flexibility, creativity, and persistence. But the payoff was worth it: This project deepened my hands-on experience with lab automation and reinforced how powerful smart systems can be when properly implemented.

Review Date: 23 May 2025 | CambTEK

The CambTEK Rapid Extraction System – A new approach to automated sample preparation of solid dosage forms for improved quality of data and productivity.

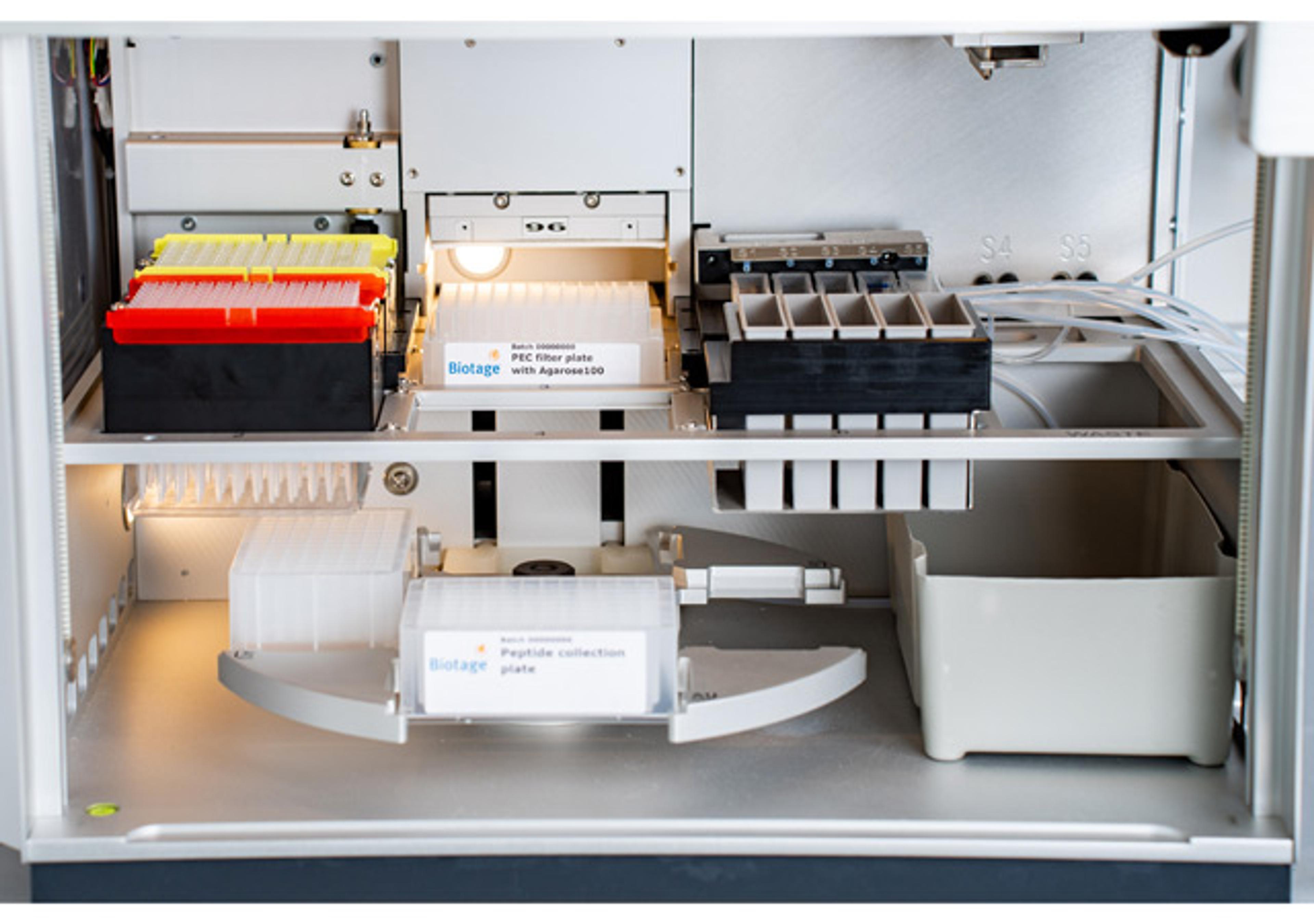

CambTEK's Rapid Extraction System (RES) delivers a step-change in performance compared with the existing methods, and is achieved using robust technologies and an intelligent consumable. Utilizing non-invasive turbulent flow with the option of ultasonics the RES delivers many advantages, including:

Reduced Sample Preparation touch time

Improved QC/QA

Increased laboratory throughput

In-process data

Easily prepare beads, capsules, gels, intermediate granulations, pellets, powders, solid & semi-solid matrices, stents, suppositories, swabs, and tablets (both normal and prolonged release)

Reduction in solvent consumption, with improved methods

Intuitive User interface and control for both skilled and non-skilled operators

Barcode sample tracking and chain of custody

Reduced cost per test, with improved methods

Application areas include: content uniformity testing, blend uniformity testing, stability analysis, tablet assay testing, capsule assay testing, drug assay testing, other impurities testing, quality analysis, batch release testing, and quality by design, dose content uniformity, batch release, stability assay, shelf life (end of life) testing, dose or drug content, drug impurities assay, bulk assay, incoming QC of raw materials, QC end product assay, pat assays or testing, at-line testing, in-process control assay test (IPCS), production QC, blend assay, blend homogeneity test, bulk drug purity assay, excipient compatibility tests, design space assays, experimental design for design space, process qualification (PQ) batches, process validation batches (PV), cleaning validation samples, occupational hygiene samples (people drug exposure monitoring – on filters), complaint samples or returns from market, design verification, incoming QC of raw materials, end product testing of solid products, compliant samples, spot testing by food inspectors.

Industry sectors include: pharmaceutical R&D and production, veterinary, food, fine chemicals, and forensics.