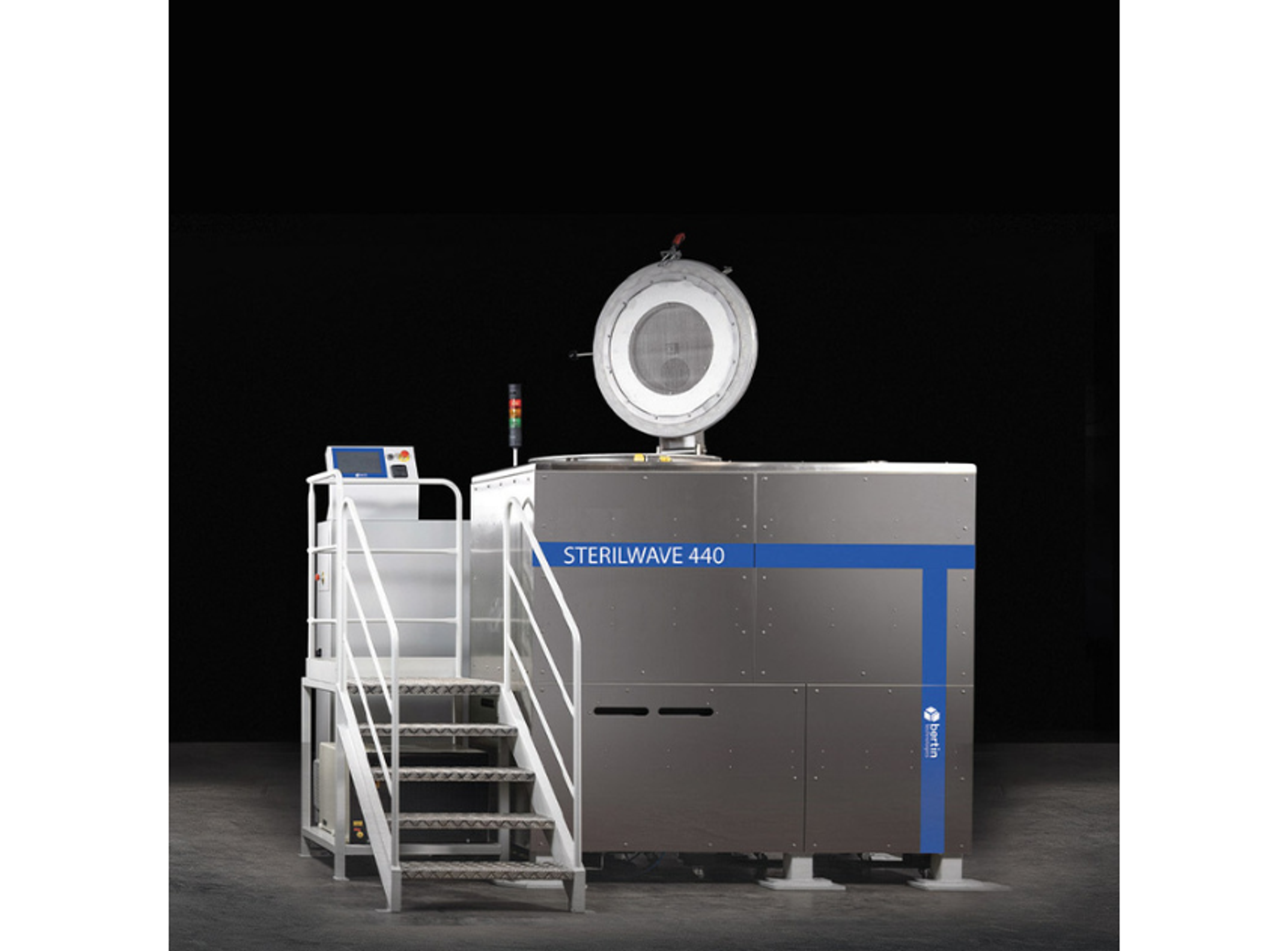

Sterilwave 440 - Onsite Bio Hazardous Waste Management Solution

The Sterilwave 440 is an efficient on-site solution for treating up to 88 kg/h of biomedical waste, transforming it into inert municipal waste through a 100% electric process combining shredding and microwave sterilization.

The Sterilwave 440, developed by Bertin Medical Waste, is designed for institutions that produce large quantities of biomedical waste. This robust equipment is ideal for hospitals and waste collection companies, offering a safe and cost-effective way to manage biomedical waste. The Sterilwave 440 uses a 100% electric process that combines shredding and microwave sterilization in a single vessel with a 440L capacity. This process transforms biohazardous waste into unrecognizable and inert municipal waste, achieving a bacterial inactivation level of up to 8log10.

Approved by the French Ministry of Health in 2012, the Sterilwave 440 meets stringent environmental and bacteriological reduction standards. It can treat up to 88kg/hr of biomedical waste, ensuring complete safety and traceability while significantly reducing operating costs.

The innovative design of the Sterilwave 440 includes a suspended vessel and rotating grinder blades that can handle all types of waste, including metallic objects. The microwave sterilization process reduces waste volume by over 80% and weight by 25%, minimizing environmental impact and operational expenses. Its compact size allows for immediate waste treatment at the point of generation, requiring only 20m² of space and no additional infrastructure.

Key Features:

- Treats up to 88 kg of biomedical waste per hour

- 100% electric process combining shredding and microwave sterilization

- Reduces waste volume by over 80% and weight by 25%

- Compact design requiring only 20m² of space

- No steam generator needed, eliminating pressure risks and liquid effluent

Applications:

- Hospitals and healthcare centers

- Waste collection services

- Epidemics and vaccines