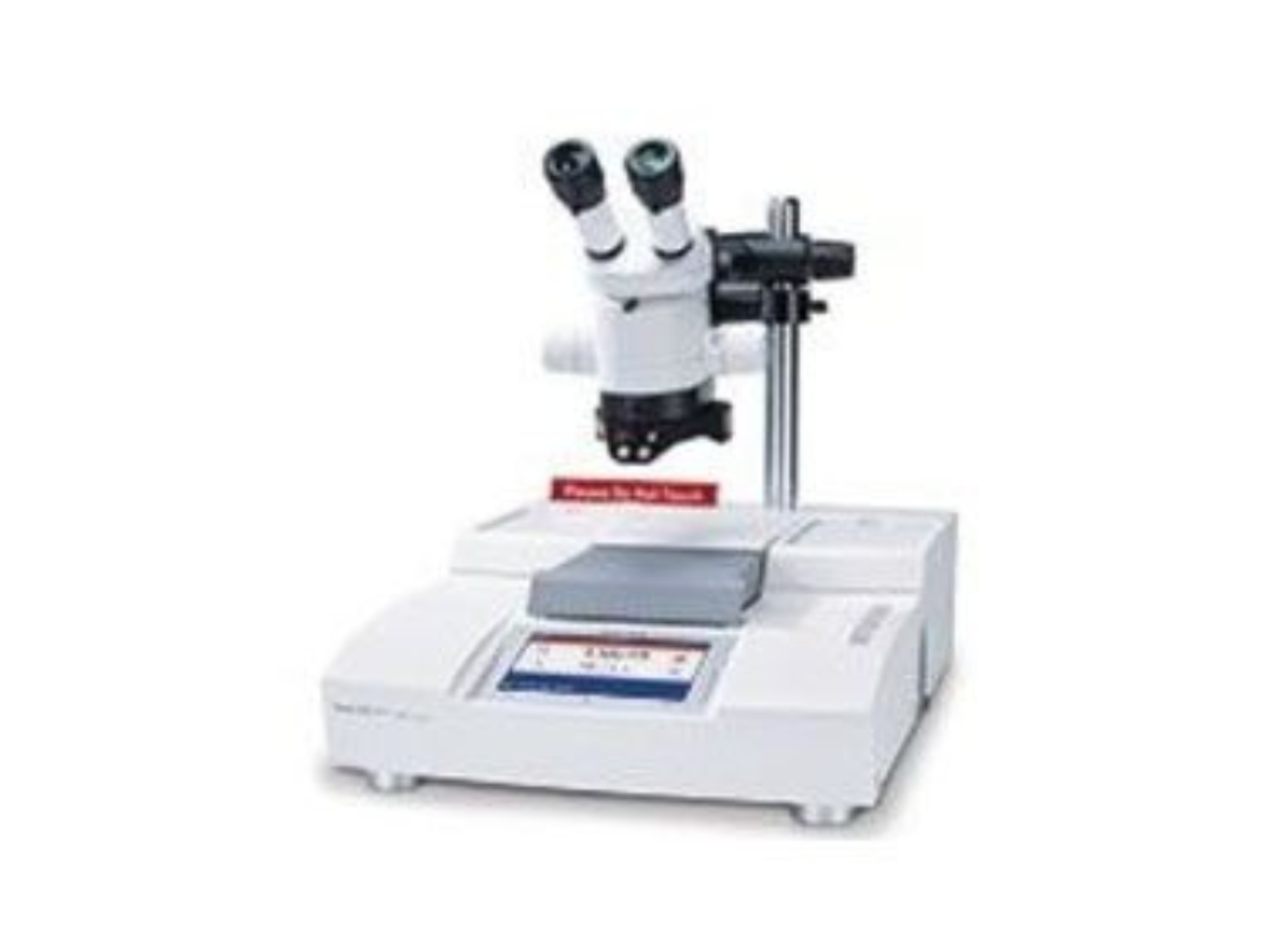

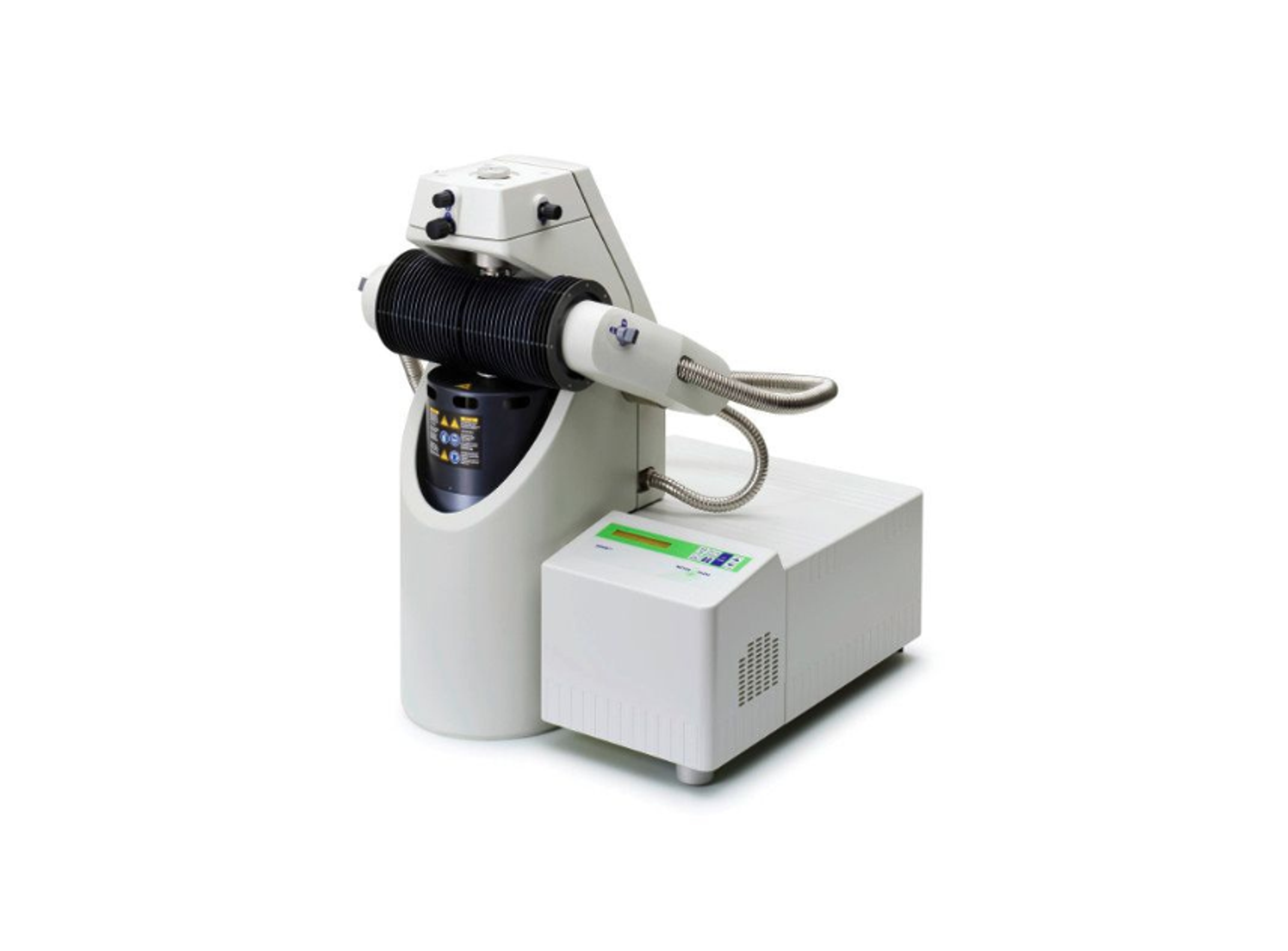

Thermal Analysis System Flash DSC 2+

Flash Differential Scanning Calorimetry - Gain New Insight into Materials. The Flash DSC 2+ is the ideal complement to conventional DSC with heating and cooling rates that cover a range of more than 7 decades.

Smart Instruments for Smart Results

Analyze wax and hydrate risks in crude oils and gas condensates

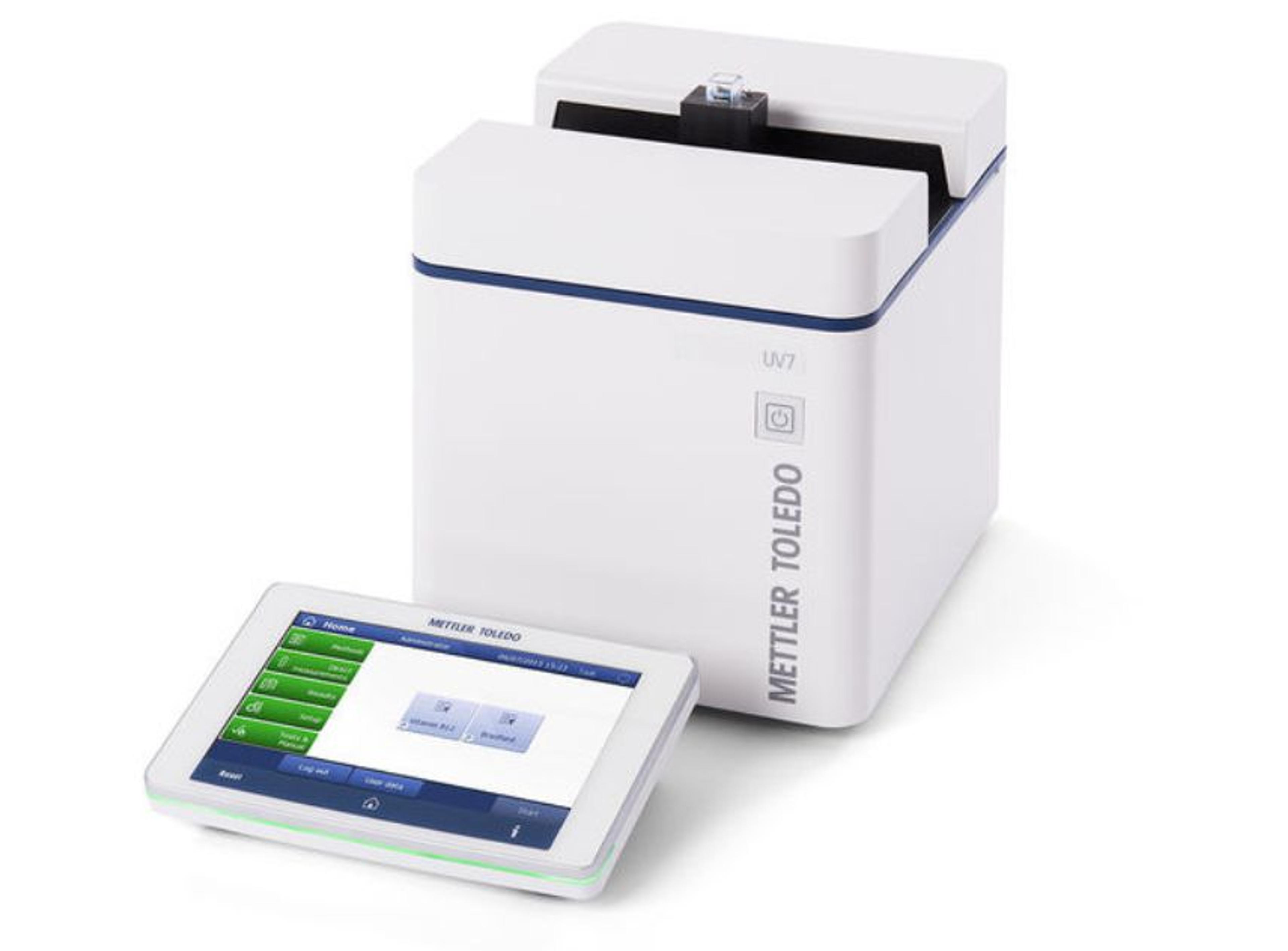

The DSC is quite effective in wax and hydrate experiments as it allows measurements to be performed at various temperature ranges, showing the corresponding quantities of solids that would deposit under various operational conditions. It comes with laboratory software that easily allows data transmission to authorized computers through a dedicated network server. As such results can be remotely fetched shortly after the tests are completed for processing, field operations support, and decision making. The graphical representation, as well as numerical data in which the results are generated, gives flexibility for calculations or direct lifting onto reports. The major snag is the time it takes for the system to boot and become ready for experiments. This is not very friendly with fast-paced industries such as oil and gas, where manhours are very precious and decisions must be made on the go. For contract jobs, the delays may increase turnaround time where there are several jobs to be delivered. It would also be interesting to see the company build a user interface into upcoming models of the machine to enable matching with simulation results. The results of the tests should also be made directly exportable into spreadsheets for easier processing by remote users who do not have the laboratory software on their computers.

Review Date: 19 Nov 2021 | METTLER TOLEDO

Differential Scanning Calorimetry, DSC, is the most important method in thermal analysis. It measures the heat flow to or from a sample as a function of temperature or time and thereby allows physical transitions and chemical reactions to be quantitatively measured.

Features and benefits of the Flash DSC 2+:

- Ultra-high cooling rates – allow materials with defined structural properties to be prepared

- Ultra-high heating rates – reduce measurement times and suppress reorganization processes

- Fast response sensor – enables the kinetics of extremely fast reactions or crystallization processes to be studied

- High sensitivity – low heating rates can also be used; scan rates overlap with those of conventional DSC