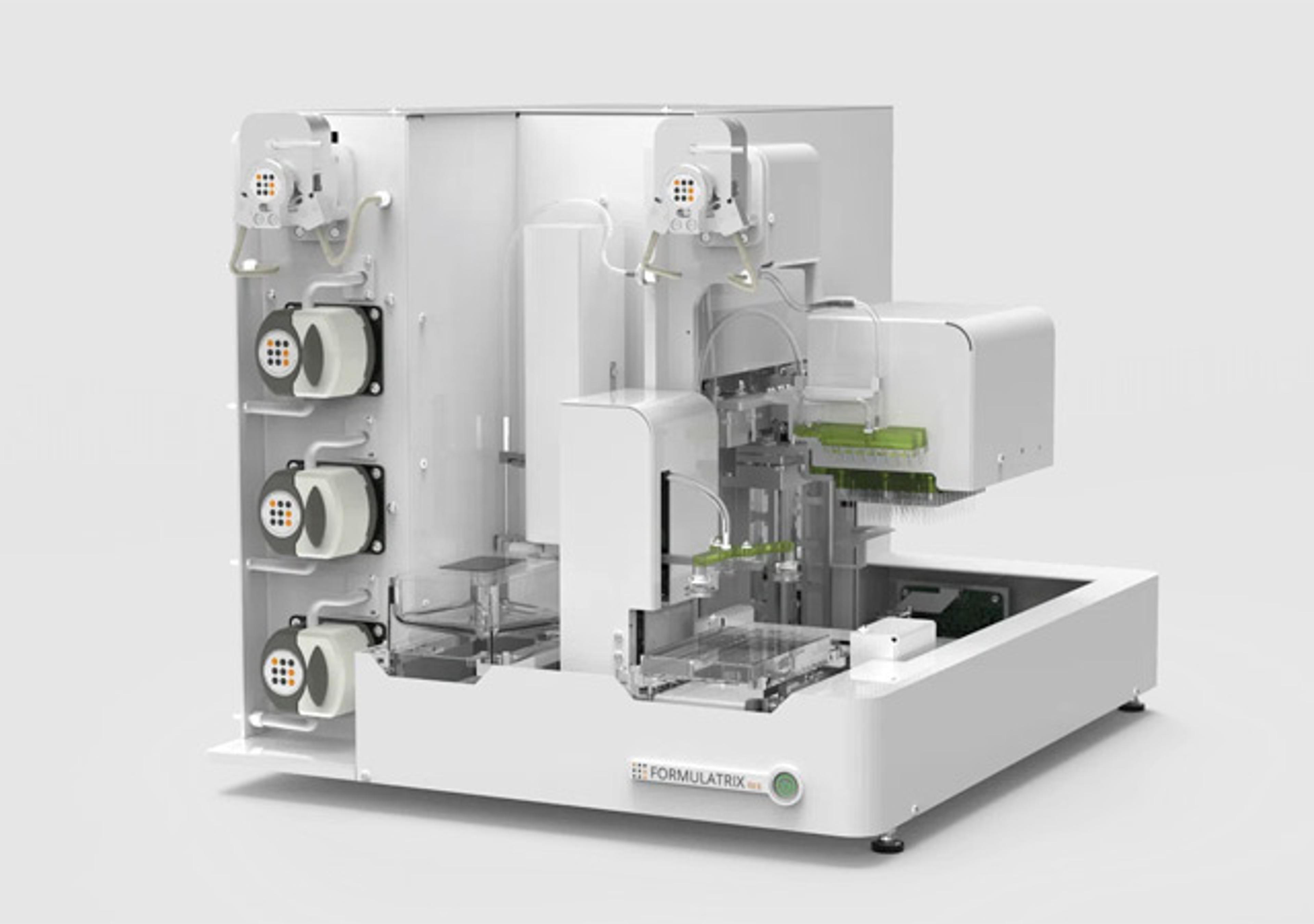

USP 4 / Apparatus 4

USP Apparatus 4 Product Details:• Cells designed for MR, CR and ER tablets, capsules, suppositories, powders, pellets, APIs, implants, medical devices, ophtalmic devices, drug eluting stents, creams, gels, suspensions, microspheres, liposomes and nanospheres • Suitable for R&D and QC, manual and automated sampling, firmware or software driven, linked to UV, UVFO (UV Fiber Optic) and fraction collector for HPLC • Evolution of t…

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

USP Apparatus 4 Product Details:

• Cells designed for MR, CR and ER tablets, capsules, suppositories, powders, pellets, APIs, implants, medical devices, ophtalmic devices, drug eluting stents, creams, gels, suspensions, microspheres, liposomes and nanospheres

• Suitable for R&D and QC, manual and automated sampling, firmware or software driven, linked to UV, UVFO (UV Fiber Optic) and fraction collector for HPLC

• Evolution of the original Flow-Through Cell system designed by Dr Langenbucher and SOTAX 35 years ago

• Compliant to USP, EP and JP for Small Volume Dissolution and Poorly Soluble Compound Testing under Sink conditions

With the Flow-Through Cell, fresh media passes continuously across the dosage form. This is called an open loop system. A semi-automated system allows samples to be taken simultaneously and collected in a fraction collector or analyzed directly by UV. Complete fractions or aliquotes can be collected in an Off-line open system. It is also possible to collect samples and analyze them. Dissolution can also be analyzed in situ in a Fiber Optics Dissolution system also called UVFO.

USP 4 Fixed and Small Volume Dissolution/Elution Testing...For small or fixed volume testing, the flow through cell can re-circulate the media across the dosage form. This is called a closed loop system. This can be an on-line closed loop with UV or UV Fiber Optic, micro volume autosampler, and even a manual sampling syringe.

The validation of the USP 4 Dissolution Testing system according to the regulations can be done by a SOTAX specially trained service engineer. The USP requires the flow rate and temperature to be qualified.