High-temperature investigation of a thermal barrier coating

17 Jul 2023Investigation of material properties at or near their operating temperatures has become increasingly important for verifying mechanical stability. For instance, the environments in a combustion chamber and the first section of gas turbines requires materials that are highly resistant to creep and oxidation. Turbine blades used in the first sections are made of creep-resistant Ni-based superalloys covered with thermal barrier coatings (TBCs). The TBC thermally isolates the core material, allowing higher gas inlet temperatures to be reached. Surface temperatures of 1200°C can be tolerated through state-of-the-art design and the appropriate choice of materials. This prevents the temperature of the Ni superalloy from surpassing 1000°C, resulting in higher energy conversion efficiency.

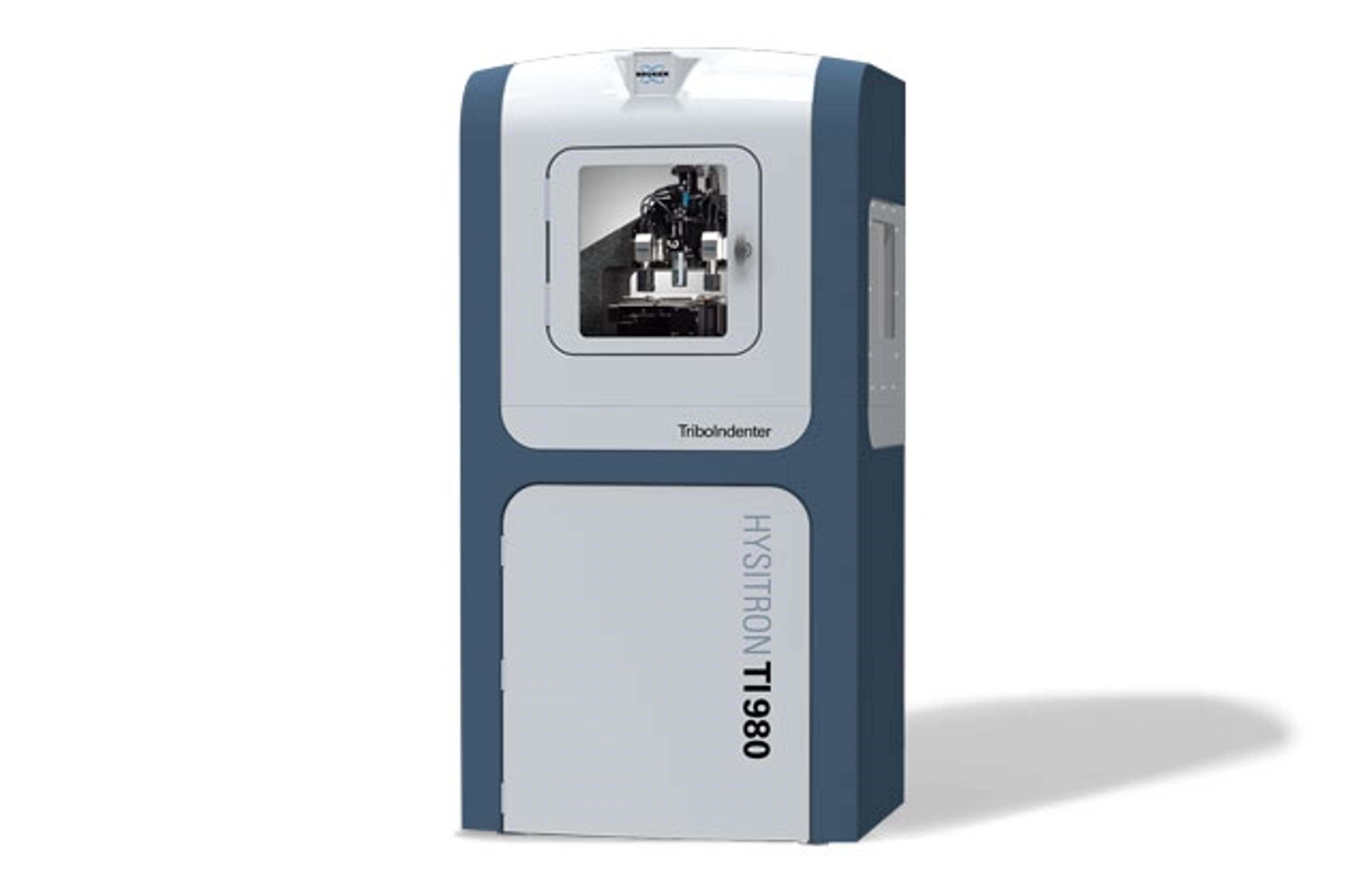

Nanoindentation at elevated temperatures is an ideal technique for verifying the mechanical stability of the different layers as test conditions approach operating temperatures. This application note details a study by Bruker Nano in which the cross-section of a Ni-based alloy coated with a 100 μm thick NiCoCrAlY bond coat layer was investigated; this configuration is comparable to a turbine blade directly after production.