Harnessing the latest bioprocessing technology in cell and gene therapy

Discover how the latest innovations in upstream bioprocessing are serving the cell and gene therapy industry

10 Jul 2023

Cell and gene therapy (CGT) is becoming a big business. It is still relatively young compared to the rest of the biologics industry, but the seminal work of Shinya Yamanaka in 2006 to generate induced pluripotent stem cells via cellular reprogramming laid the foundations for the growth in CGT that we observe today. Exciting new opportunities to bring life-saving treatments to the world are emerging as we move away from autologous therapies towards more allogeneic applications.

However, this brings new challenges, particularly in manufacturing, new standards, protocols, and processes are needed to render allogeneic therapies reliable and scalable. The latest innovations in upstream bioprocessing for CGT are eliminating the need for complex validation procedures, reducing regulatory burdens and accelerating manufacturing timelines. With the use of artificial intelligence and machine learning to optimize bioprocess parameters and predict outcomes, further innovations are just around the corner.

In this editorial, we speak with Lina Tao, Vice President of Eppendorf’s Bioprocess Unit based in North Rhine-Westphalia, Germany, who is in the forefront of bioprocessing innovation for CGT. A biologist by training, Tao ascended to her current role through marketing and sales positions and clearly knows a thing or two about delivering for customers in the CGT field.

Allogeneic therapies – riding the crest of a wave

Tao reminds us that the first stem cell-based therapy was clinically approved in 2009, marking a significant milestone in the development of CGT. As the field continues to evolve, she notes the shift from autologous to allogeneic therapies in which, healthy donor cells are modified to treat multiple patients, rather than tailoring treatments to each individual. This has had implications for bioprocessing, as Tao observes, “Traditionally, stem cell and CGT processes have been developed using 2D static systems which sufficed for research primarily focused on autologous applications,” she says. “But this allogeneic approach now brings new challenges as the processes need to be standardized and scalable,” she adds.

2D static processes utilize plates and flasks that do not provide enough capacity or the expansion capability to cultivate enough cells. And that is where Eppendorf’s bioreactor technology comes in.

Addressing bioprocessing challenges with Eppendorf solutions

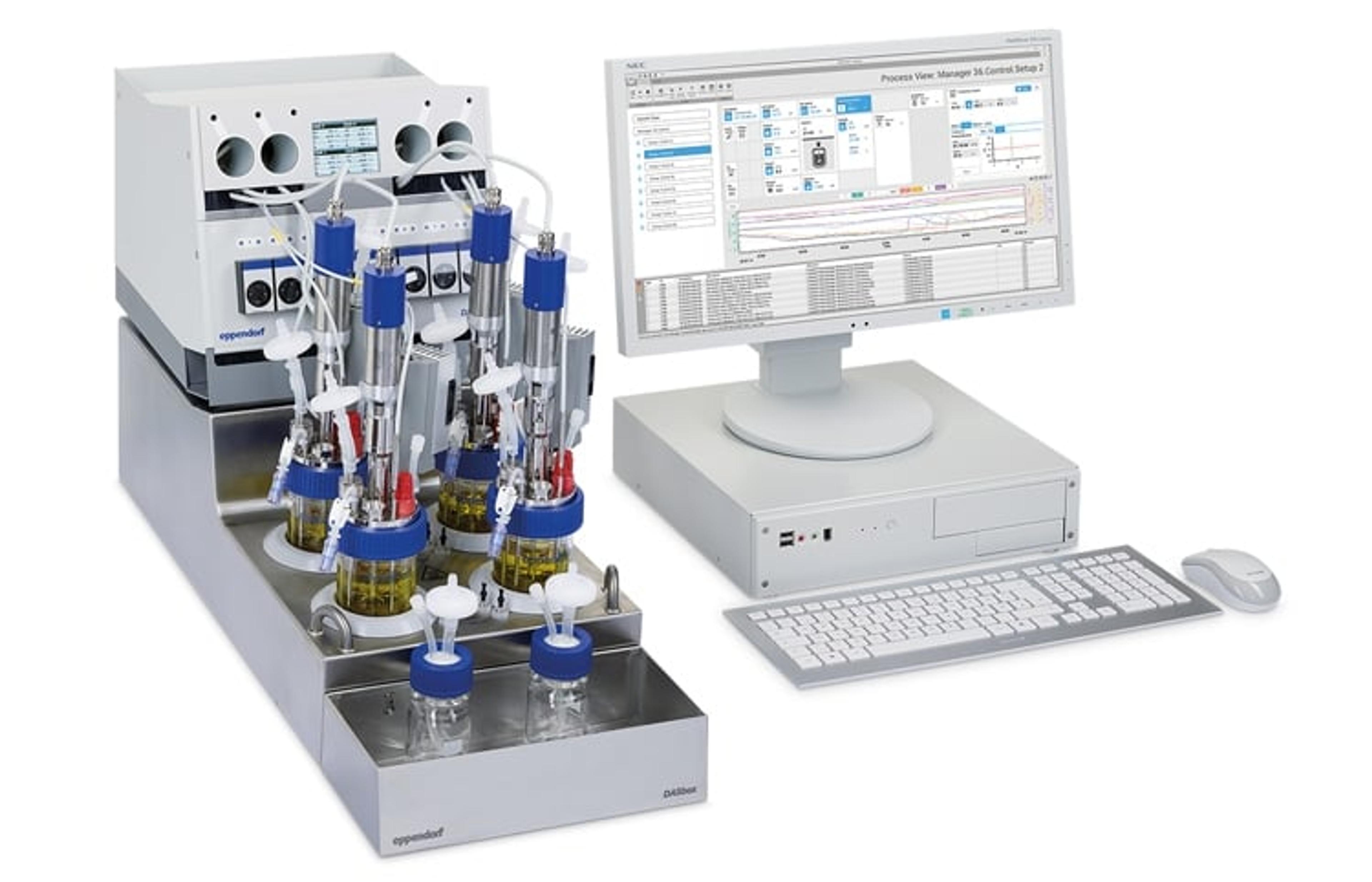

Eppendorf’s stirred-tank bioreactors are an ideal solution for scale-up, operating from a few milliliters up to around 50 liters with single-use solutions. “Processes can be tested in small volumes and the technology transfer from small to larger volumes is assisted by appropriate software solutions that calculate the parameter settings needed for a straightforward scale-up process,” Tao explains.

She further elaborates that the parallel control of multiple bioreactors in Eppendorf systems speeds up process development, fosters standardization, and saves costs – especially when single-use bioreactors such as the BioBLU® system are used, “Single-use bioreactors eliminate the need for time-consuming and costly cleaning and sterilization processes associated with traditional stirred-tank bioreactors,” Tao asserts. “This streamlines the workflow, reduces downtime between batches, and enables faster turnaround times for production,” she adds.

Single-use systems also eliminate the need for complex validation procedures, thereby reducing regulatory burdens, as Tao summarizes. “Overall, the adoption of single-use bioreactors in the CGT industry represents a transformative shift, offering improved efficiency, flexibility and cost-effectiveness, ultimately supporting the commercialization of life-changing therapies,” she says.

It is apparent that even shear stress-sensitive cells such as stem cells can be cultivated successfully in stirred-tank bioreactors, something that Eppendorf have been doing for more than a decade now. Their customers are now achieving yields of more than 35 million cells per milliliter.

3D-stirred bioreactors – a new ‘gold standard’?

3D-stirred bioreactors with single-use technology will become the new gold standard for CGT upstream bioprocesses.

Lina Tao

Eppendorf SE Bioprocess Unit

According to Tao, there are numerous reasons why 3D stirred-tank bioreactors offer advantages over traditional 2D cultivation platforms as well as other established cultivation systems, such as bags. The most obvious reason is the way in which they provide a more physiologically relevant microenvironment for culture, with improved mass transfer, nutrient distribution, and waste removal. They also allow for higher cell densities and can facilitate the production of more complex cell types for the development of advanced therapies. Add in single-use technology such as BioBLU and the advantages stack up even further, as Tao enthuses, “Overall, we believe that 3D stirred-tankbioreactors with single-use technology will become the new gold standard for CGT upstream bioprocesses due to their superior performance, versatility and ease-of-use,” she says.

Eppendorf Bioprocess offers a range of solutions for CGT manufacturing, from small-scale research and development to production scale. Tao explains, “Our bioreactors and systems such as the DASbox® or SciVario® twin provide flexible and customizable platforms for optimizing cell expansion and differentiation, as well as gene transfer and expression,” she says.

Allied to Eppendorf’s advanced analytics and monitoring tools (and single-use bioreactors), these technologies offer consistent and reproducible manufacturing.

Staying ahead of the game – a culture of innovation

Collaboration with our customers is an essential part of the Eppendorf DNA.

Lina Tao

Eppendorf SE Bioprocess Unit

According to Tao, her team at Eppendorf has many successful examples of collaborations that have advanced bioprocessing in the CGT field. “We collaborate with the leading scientists and key opinion leaders in the field to stay at the forefront of innovation. We take the approach of listening and understanding our customers’ challenges and pain points, and we aim to develop solutions to overcome these challenges and advance their development,” she asserts. In one such example, Tao worked with Dr. Robert Zweigerdt at the Hannover Medical School in Germany to develop a special 8-blade impeller, optimized for the cultivation of stem cells as aggregates. Using this with the DASbox controller, Zweigerdt achieved greater than 35 million cells per milliliter yield after just seven days of cultivation. Tao is therefore keen to point out that, “collaboration with our customers is an essential part of the Eppendorf DNA."

Eppendorf’s 70-year history in cell culture bioprocessing and more than a decade of experience in supporting the CGT industry underlines its credentials as a leader in bioprocessing technology development. In conclusion, Tao offers some tantalizing thoughts about what the near future may hold in bioprocessing, “We expect to see continued advancements in bioprocess automation, such as the use of artificial intelligence and machine learning to optimize process parameters and predict outcomes,” she enthuses.