How to improve accuracy and consistency in cell culture research with the right filtration system

Nate Starbard, Thermo Fisher Scientific, discusses how to overcome common filtration challenges in the lab

26 Jul 2020

In this SelectScience interview, we hear from Nate Starbard, global product manager for laboratory filtration products at Thermo Fisher Scientific, about his team’s work to help overcome common filtration challenges. Starbard discusses how Nalgene Rapid-Flow filter units and bottle tops are enabling scientists working with cell cultures to trust the accuracy and consistency of their results through the COVID-19 crisis and beyond, and shares top tips for filtration success to ensure time is not wasted on failed experiments.

SS: Tell us a little about your role at Thermo Fisher Scientific

NB: I work with our various sales and customer support teams as well as internal research groups to make sure that our filtration portfolio is meeting our customer’s needs and that we are developing products to continue moving the market forward.

SS: What are some of the current trends in biopharmaceuticals and how is Thermo Fisher Scientific supporting customers working on these projects?

NS: Thermo Fisher Scientific is doing everything it can to support the current COVID-19 situation and while this is certainly forefront, we are not losing sight of both where the market was going prior to the pandemic and what permanent changes will result from it. Certainly, there will be a long-term increased focus on virus and vaccine research, particularly with recombinants, as well as additional work on rapid testing. The testing piece dovetails with what we were already doing with CRISPR and genomics. Thermo Fisher Scientific’s breadth and depth of both expertise and products means all of our various groups from laboratory essentials to microbiology to bioproduction are able to build upon and support one another to address whatever the market may need.

Science is moving too fast to lose time on failures or second-guessing results

Nate Starbard, Thermo Fisher Scientific

SS: What are the most important considerations for scientists working with cells?

NS: Consistency, accuracy of results, and most importantly - time. Scientists realize that the true cost of research is not in the devices or media they purchase but in the time to conduct their work and being able to have consistent, reliable results. Nothing is more costly than a contaminated experiment or poor results from not using a quality product for your filtration or any step of the process. Science is moving too fast to lose time on failures or second-guessing results.

SS: Tell us about Nalgene Rapid-Flow filter units and bottle tops – what are the key benefits to scientists working in biopharmaceuticals?

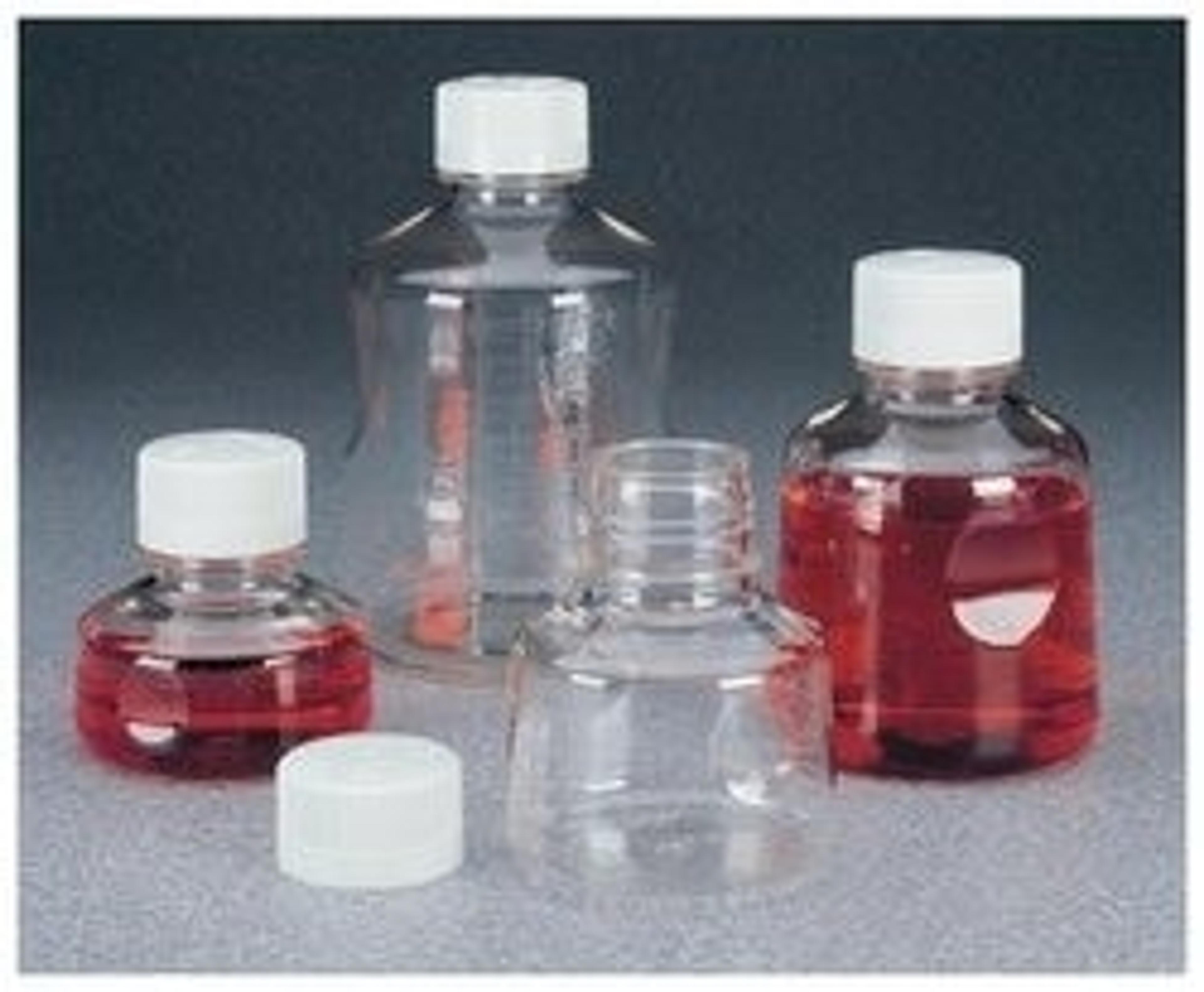

NS: Our Rapid-Flow devices have a number of features that allow them to process media and related fluids faster and with less chance of premature clogging than any competitive devices. In addition to the filter itself, the resins and receiver bottles used are built on the Nalgene family of labware which is celebrating its 70th birthday this year. Throughout that entire time, the brand has always exemplified quality, consistency, and has continued to evolve.

SS: What are some examples of projects your customers are working on using these products?

NS: Nalgene Rapid-Flow devices are used whenever customers are doing cell culture research. Cancer treatments and monoclonal antibodies have been a key focus for the past several years. Our devices also have some added benefits and extra certifications for stem cell and embryonic related work, where applications are very sensitive to the quality of products used for research.

Visit the SelectScience Biopharmaceuticals Special Feature for more on the latest methods and technologies

SS: What do you see for future trends in biopharma research?

NS: Specifically, with regards to vacuum filter units and bottle top filters, we continue to see the shift towards high cell density mammalian cultures. The increase in plant-based media has also highlighted the need for 0.1um devices to prevent mycoplasma contamination. These are both areas we are continuing to address.

SS: What are your top tips for selecting the right filtration products?

NS: Quality is always going to be number one. Again, the cost of a contaminated trial in terms of lost time or delayed results is going to be the most critical factor in what device is used. For me, right-sizing of devices is also an important aspect that is often overlooked, especially when dealing with hard to filter solutions. There is sometimes a tendency to use a larger device as insurance against clogging, however, using the smallest device that can reliably filter your volume reduces extractables, binding, and plastic waste. Not all filtration membranes or devices are created equal and so performance should be looked at during selection and not just the rated volume.

Learn more about how your choice of filtration device can impact overall performance in this application note, plus read the case study with virologist Dr. Ryan McNamara, Translational Fellow at UNC Chapel Hill and Lineberger Comprehensive Cancer Center.

Do you use Thermo Fisher Scientific products in your lab? Write a review today for your chance to win a $400 Amazon gift card>>