Improving Food Safety at the United States Department of Agriculture

Find out how USDA ARS scientists use advanced separations technology to reduce food contamination risk to human health and the environment

17 Jul 2017

The Agricultural Research Service (ARS) is the U.S. Department of Agriculture's chief scientific in-house research agency. Yelena Sapozhnikova is an ARS research chemist working on improving analysis for contaminants in foods. SelectScience speaks to Yelena to learn about the use of gas chromatography and liquid chromatography in her research.

SS: Please could you confirm your name, job title and place of work?

YS: My name is Yelena Sapozhnikova, Ph.D., Research Chemist, United States Department of Agriculture, Agricultural Research Service, Wyndmoor, PA, USA.

SS: Please could you give us a brief overview of your job responsibilities and daily workload?

YS: My job responsibilities include developing innovative technologies for the detection of chemical contaminants in foods. I am conducting research designed to develop, evaluate, and transfer novel analytical methods for the detection of contaminants in foods to support regulatory agencies’ and industry needs. My research focuses on improving every aspect of sample preparation, including sample processing, extraction, cleanup, and instrumental analysis with gas chromatography (GC), liquid chromatography (LC), and mass spectrometry (MS) detection. The bottom line is how to make sample preparation, instrumental and data analysis more efficient, easier, and faster, while providing high quality accurate results for multi-class, multiresidue analysis.

Improving food safety

It is hard to overestimate the importance of accurate analysis

Dr. Yelena Sapozhnikova United States Department of Agriculture

SS: Could you describe the current projects that you are working on?

YS: My current research projects focus on improving chemical residue analysis in complex food samples, including high-throughput sample preparation, fast analytical separations (GC and LC), advanced MS detection, and method validation to advance the analysis, and, ultimately, improve food safety.

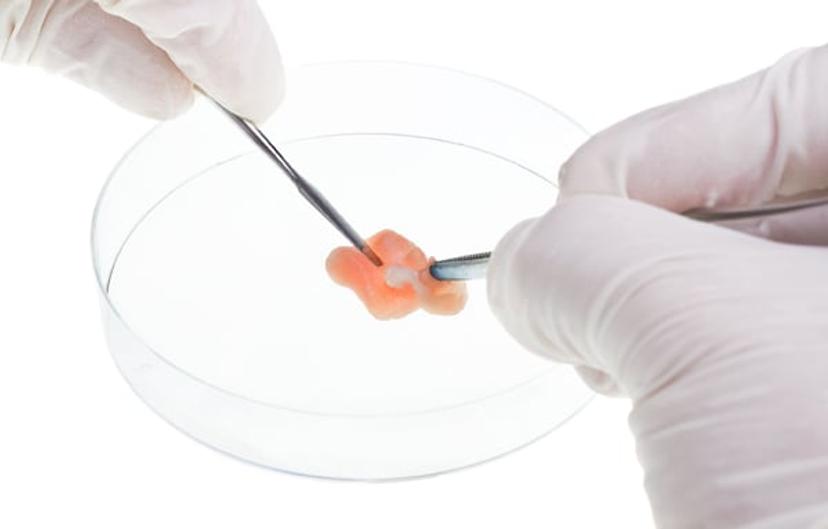

One project we are working on focuses on the validation of analysis of pesticides and persistent and emerging environmental contaminants in meats (chicken, pork and cattle) using batch QuEChERS extraction, automated mini-solid phase extraction (SPE) cleanup for removing interfering components from the complex meat extracts, followed by instrumental analysis using low pressure GC- (LPGC) and UHPLC-MS/MS in parallel. We have recently demonstrated that automated Instrument Top Sample Preparation (ITSP) with mini-SPE cleanup provides rugged and efficient cleanup for many food matrices. Now we are evaluating its application in the analysis of pesticides recommended by the U.S. Environmental Protection Agency for routine monitoring in meats. Our multi-class, multiresidue method covers approximately 300 contaminants (pesticides, and environmental and emerging contaminants) that can be analyzed from one sample simultaneously.

Both fast LPGC-MS/MS and UHPLC-MS/MS are utilized in parallel (10 min each) to cover as many chemical contaminants as possible, and 60 contaminants are analyzed by both instruments, providing an additional degree of confirmation using an orthogonal technique. Once the method is validated, we plan to transfer it to USDA’s Food Safety and Inspection Service (FSIS), which conducts routine monitoring of meats for pesticides. We also plan to use this new method for a market survey of contaminants in the US meats to generate data on their occurrence and levels.

In another exciting project, we are identifying chemicals migrating from food packaging materials (stretch plastic film/cling film) into packaged meats. Our goal is to identify and characterize contaminants with high potential of migration that can be of toxicological significance. Plastic films are made from polymeric materials, which are generally inert, and not expected to migrate into foodstuff. However, chemicals added to polymeric films to improve or alter their properties are potential candidates for migration. These include antioxidants, light stabilizers, plasticizers, thermal stabilizers, lubricants, antistatic agents, etc., plus non-intentionally added substances - chemical impurities, contaminants, and chemicals formed during degradation and/or reaction of added chemicals. We plan to develop a new analytical method for multi-residue analysis of food packaging contaminants, to help enhance food safety testing.

Testing food packaging chemicals enhances food safety

Sergey Ryzhov © 123rf.com

Utilizing sensitive analytical techniques

SS: How does the use of gas chromatography (GC) and mass spectrometry (MS) help you to achieve your research goals?

YS: GC with triple quadrupole tandem mass-spectrometry (GC-MS/MS) is currently the gold standard in quantitative analysis, and the most commonly used analytical technique in targeted analysis. We use it daily for the analysis of GC-amenable pesticides and environmental contaminants in foods. Modern MS instruments are very sensitive, and enable measurement of contaminants at or below their tolerance levels.

As I mentioned, in our current research project we cover approximately 300 analytes in one instrumental run, with >200 contaminants analyzed by GC-MS/MS. A typical GC run to separate >200 analytes commonly takes 40-45 minutes, but we use fast GC, utilizing low pressure (LP) vacuum outlet set-up, that enables chromatographic separation to occur in 10 minutes. The design of LPGC is very simple, and it can be implemented on nearly all GC-MS instruments. Compared to conventional GC analyses, which mostly use columns 30 m long with 0.25 mm internal diameter (i.d.) and 0.25 µm film thickness, LPGC utilizes short (10 -15 m), wide (0.53 mm i.d.) megabore columns with thick film (0.53 µm) operated under vacuum conditions, which speeds up the separation by reducing viscosity of the carrier gas, thereby leading to a higher optimal flow rate for the greatest separation efficiency. To keep the inlet at normal operating pressures, the analytical column is commonly coupled to a short, narrow uncoated restriction capillary that also acts as a guard column. Several vendors offer megabore analytical columns for LPGC, all of which we have evaluated in our LPGC studies. Moreover, some vendors already provide pre-connected custom columns of requested types and dimensions useful for LPGC.

In addition to greater speed, and the resulting higher sample throughput, LPGC provides other benefits, including lower detection limits, less chance of analyte degradation, reduced peak tailing, increased sample loadability, and more ruggedness. Unfortunately, though, very few laboratories take advantage of this technology in spite of obvious benefits. I have recently developed and taught a short course at the Pittcon 2017 meeting to encourage other scientists to benefit from the advantageous LPGC.

SS: What is the importance of monitoring food contamination and what impact do you hope your research will have?

YS: The monitoring of contaminants in food helps to enforce regulations, reduce incidents of unlawful applications of prohibited substances, and, ultimately, reduce risks to human health and the environment. With the ever-increasing global food trade, effective, accurate and affordable analytical methods for monitoring food contaminants become essential to routine testing. False-positive results in testing can be detrimental to food safety and costly to the food industry. It is hard to overestimate the importance of accurate analysis. Our research results in new, efficient, simple, and accurate analytical methods that regulatory government and commercial testing laboratories can readily use for routine analysis of contaminants in foods.

SS: Based on your experience in method development, do you have any advice for other scientists working in a similar field with the same technology?

YS: Follow new developments and make improvements to current methods whenever possible. New technologies develop very quickly, and we, as scientists, should always be at the cutting edge, adopting what is available to make analysis better, faster, and more efficient. Attend scientific meetings, educational seminars and webinars to learn new developments in the field, talk to other scientists and vendors to learn about the latest technologies.

Expert commentary provided by Ramkumar Dhandapani, GC Technical Manager for Phenomenex:

Modernization of chromatographic methods is very important both from an analyst’s perspective and from the consumer’s perspective. Use of modern separation techniques results in high resolution separation, short run time, reliable quantitation and eventually leads to high throughput analysis. Starting from sample preparation to analysis, there are a lot of steps that need detailed attention to achieve good chromatographic separation and sensitivity. The sample preparation process itself can be as simple as filtering the sample to remove particulates, or as complex as solid phase extraction (SPE).

Phenomenex offers a variety of sample prep solutions to meet the needs of the modern world. roQ QuEChERS has been one of the food industry’s standards for improved extraction of pesticides and effective removal of matrix from food samples. Advanced sample cleanup such as SPE offers cleaner extracts that eventually extend the analytical column and instrument’s lifetime. We have explored multi-residue analysis in various food matrices using various sample preparation techniques in combination with orthogonal instrumentation:

- Chlorinated Pesticides from Poultry Fat using Strata SPE and GC ECD

- Multi-Residue Pesticide Screening by GC-MS

- Comprehensive LC-MS/MS Analysis of over 180 Pesticides with a Kinetex® Biphenyl Core-Shell LC Column

- Multi-class antibiotics screening in meat using QuEChERS and LC-MS/MS

As a chromatographer, I believe that chromatographic separation of analytes on highly efficient column dimensions, followed by cutting-edge instrumentation, helps to accurately quantitate multi-class pesticide residues in a single run. With Zebron GC columns, the options are infinite as we have a variety of proven selectivities for pesticide analysis, multiple dimensions to suit customer’s separation needs and a column protection option with ZB-Guardian that is a seamless union of the guard column to the analytical column. At Phenomenex, we feel proud to contribute to food quality and safety testing by providing complete chromatographic solutions through sample preparation, LC, and GC products.