Malvern Instruments Publishes Fresh Insights into Laser Diffraction Particle Sizing

Malvern Instruments has released two new articles detailing its work in engineering and emulsification

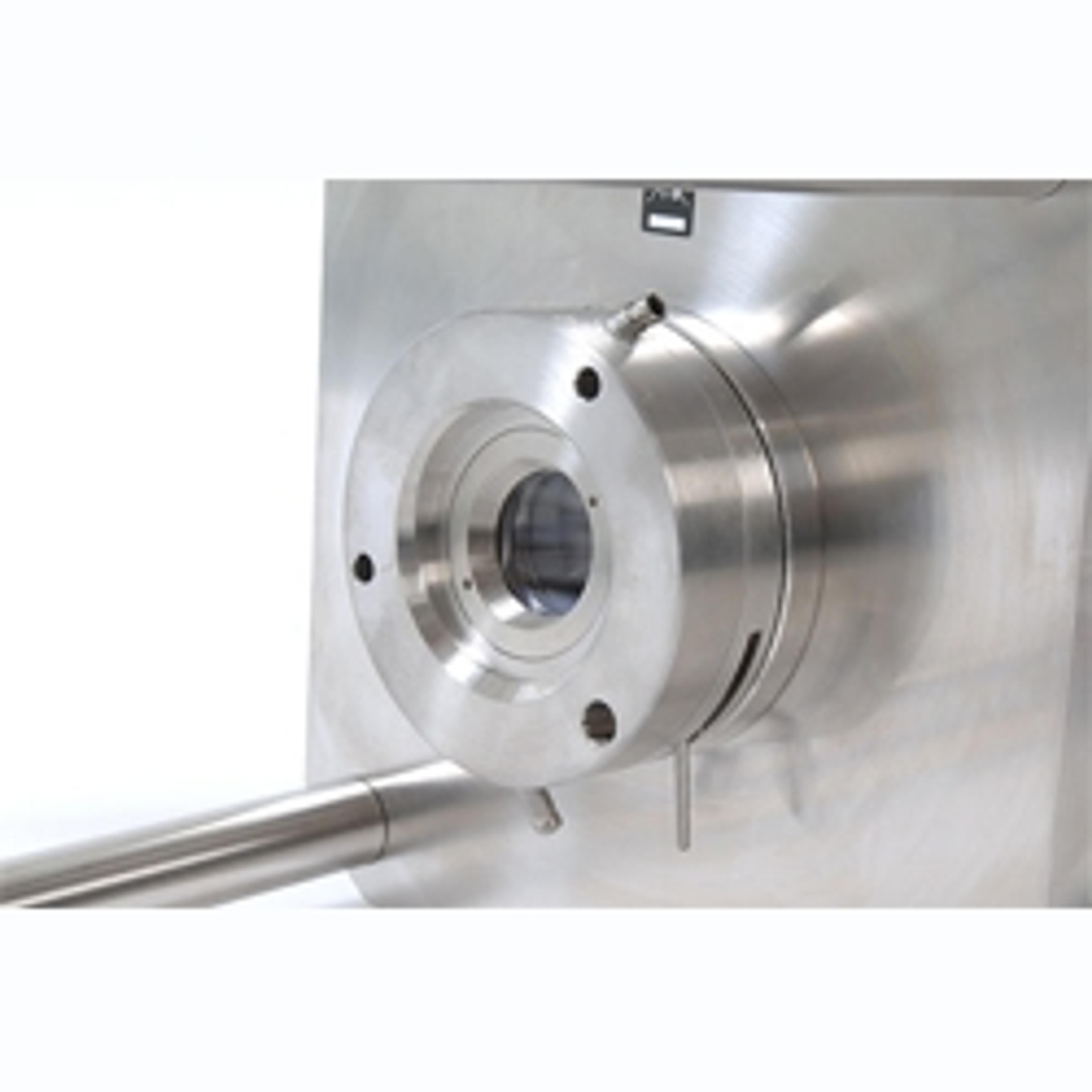

3 Sept 2017In the first article, Malvern Instruments look at how, from the starting point of an appropriate wet sensor, laser diffraction systems can be engineered to deliver to the needs of different process applications. It includes a case study involving the control of an emulsification unit for the production of oil and water emulsions illustrates what can be achieved and the benefits delivered.

Read the article here: Laser-diffraction Particle Sizing Pays Dividends for Wet-Process Monitoring

A second article details how Zementwerk Berlin GmbH & Co KG has been using Insitec on-line laser diffraction particle sizing by Malvern Instruments, to optimize cement production for more than a decade.

This collaborative article reviews the company’s experience of real-time particle sizing, examining the implementation of closed loop control and the economic benefits that advanced control strategies have delivered. These include an increase in plant throughput of 2%. The use of on-line analysis in the production of ‘environmentally friendly’ slag cements is a particular focus.

Read more here: Reviewing a Decade of Online Particle Sizing

Have you worked with any Malvern Instruments products? If so, write a review here!