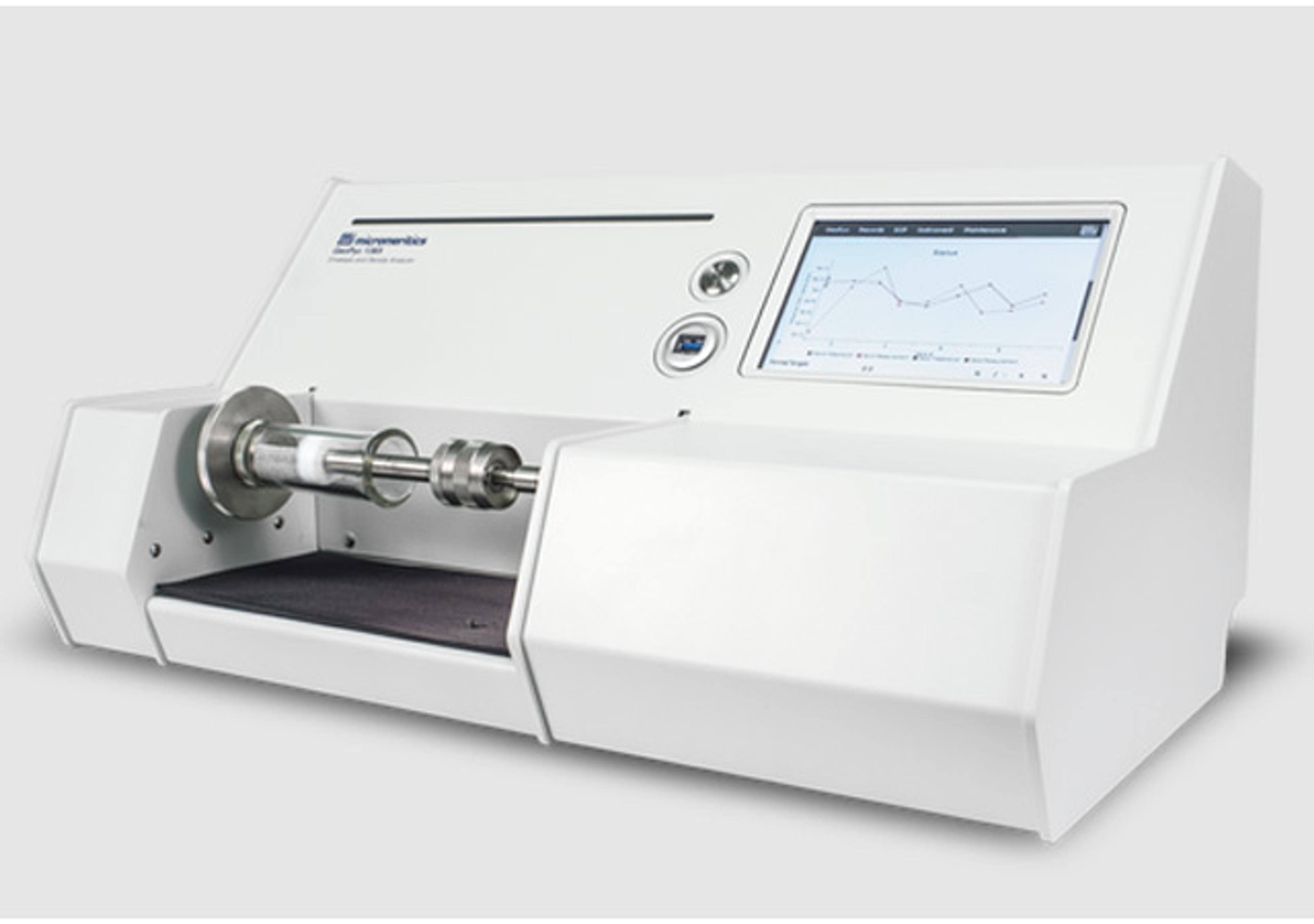

Insitec Dry Online Particle Size Analyzer

The industrially robust, technologically proven process particle size analyzer

Easy operation and reproducible result

Pharmaceutical

This is most widely use in pharmaceutical industry for determining particles size of raw material.

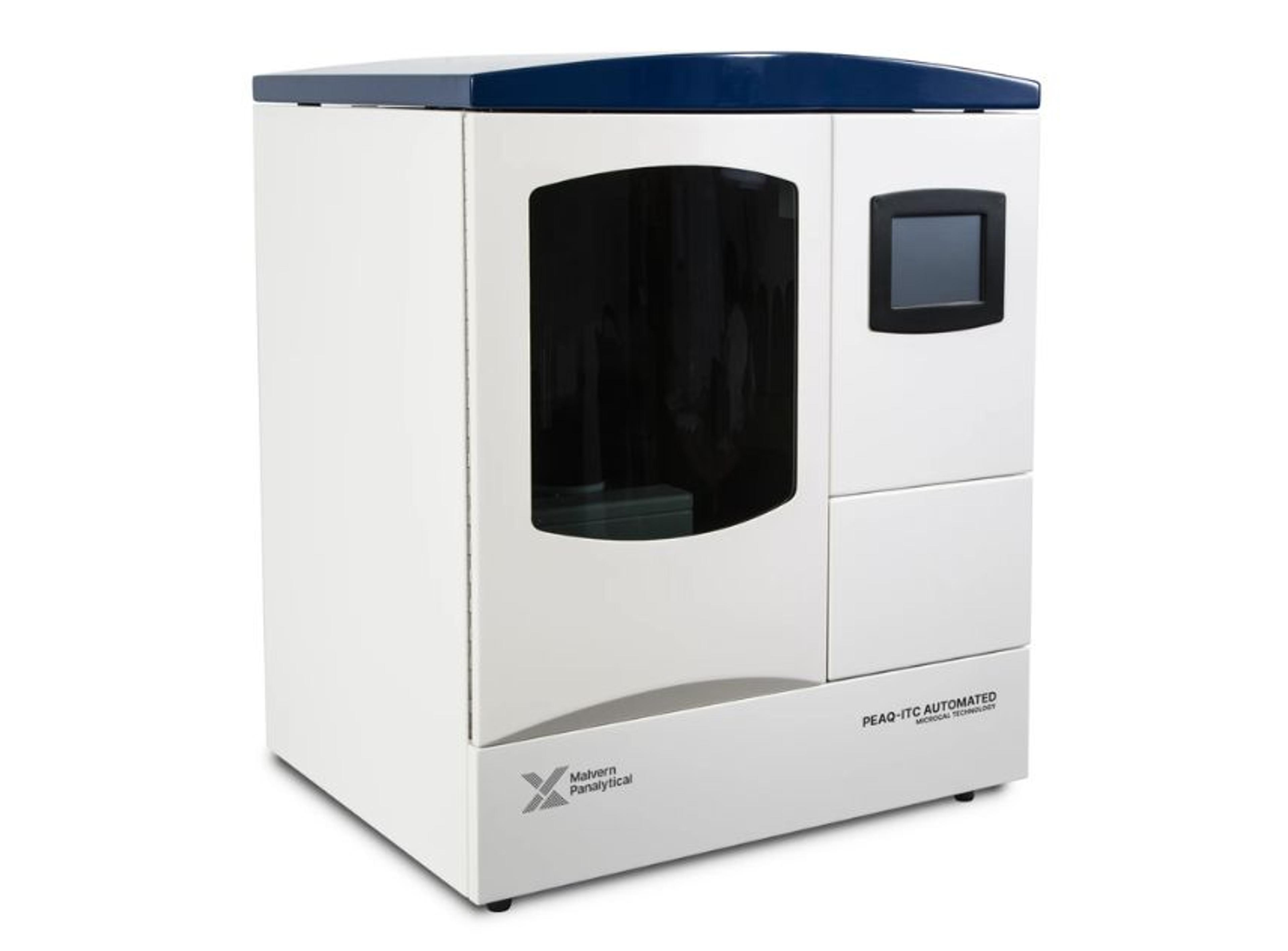

Review Date: 14 Apr 2023 | Malvern Panalytical

Very good instrument for wet analysis of the sample.

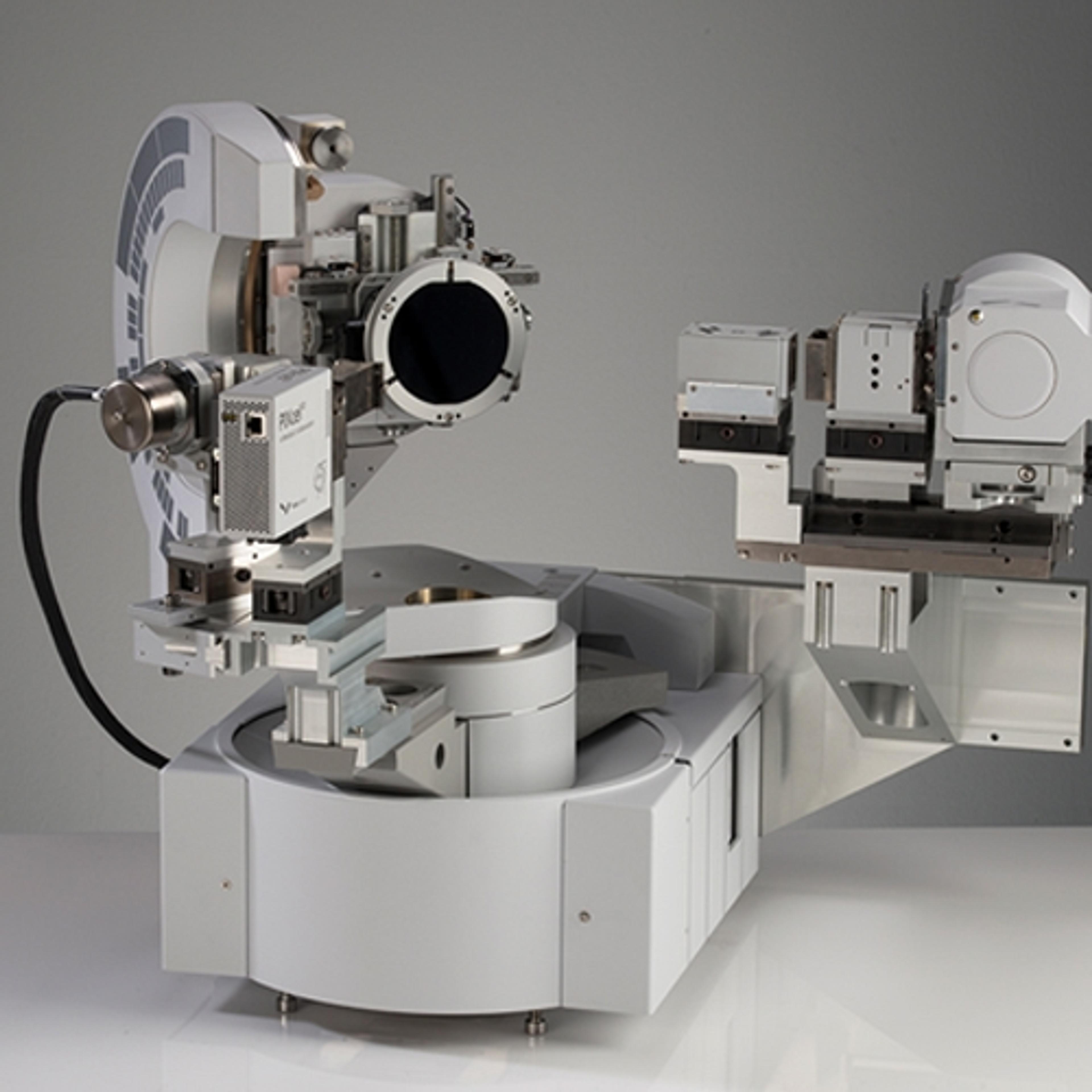

Particle Size Analysis

Good insturment for the particle size analysis. It gives excellent results.

Review Date: 1 Dec 2021 | Malvern Panalytical

Very valuable instrument that produces great results!

Analyze particle size of product

This instrument is used infrequently, but always produces desired results. It is a robust machine that needs little to no attention. Very easy to use.

Review Date: 24 Jan 2020 | Malvern Panalytical

Engineered to withstand the rigors of the process environment, Insitec Dry particle size analyzers use laser diffraction technology to measure particles in the size range 0.1 to 2500 µm. Insitec Dry can be configured to suit practically every dry particulate process, delivering real-time monitoring and control 24/7.

Insitec Dry is an ATEX/FM approved intrinsically safe laser diffraction online particle size analyzer for process monitoring in gas or dust zoned hazardous environments rated as zone 0,1 and 2 or 20, 21 and 22. The equipement is used to monitor and control processes ranging from abrasive bulk powders to foods, fine chemicals and pharmaceuticals with strict hygiene standards and subject to stringent regulatory control. To ensure representative sampling, process interfaces are tailored to meet custom needs whether pilot scale or hundreds of tonnes per hour.

All Insitec installations are tailored to the unique requirements of the application. They range from simple at-line, manually-fed systems to fully automated, validated on-line solutions for continuous monitoring and multivariate control. Malvern Panalytical works in partnership with its customers, providing expertise, hardware and software, where and when it’s needed. This ensures cost- effective, successful project implementation and a positive return on investment.

Insitec Dry Features:

- Base model hardware manufactured to GAMP5 standards and compatible with CIP/SIP requirements to meet specific manufacturing specifications.

- Easy to use software and fully automated operation to minimize training requirements and release operator time.

- Integration with existing control platforms to simplify development of automated control protocols.

- High reliability of >95% with little downtime, minimal maintenance and maximum ROI.